06-01-2012, 02:26 PM

06-01-2012, 02:26 PM

|

#11 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 710 Times in 458 Posts

|

Quote:

Originally Posted by EdKiefer

If you try an add very short runners with each cylinder having TB, this tends to opimize high rpm usage . If for example to modified a vehicle that has single TB with one plenum and long runners you will lose a lot of low end torque and throttle will be extremely sensitive . only way around will be extremely small TB.

|

Yah, I'd be looking at a 20 mm throttle bore if I were to be doing this to my truck. To my knowledge, that's in the realm of lawn mowers and similar small engines.

The big problem with this arises from trying to adapt it to the existing engine electronics. There is no more reliable vacuum source from which to do speed-density tuning (MAP and IAT). MAF engines should not have this problem, though.

A secondary problem arises from implementing engine idle. That's pretty much independent of whether the engine uses MAF or speed-density.

A tertiary problem arises from powering vacuum-dependent accessories, like power brakes and cruise control.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

06-01-2012, 03:41 PM

06-01-2012, 03:41 PM

|

#12 (permalink)

|

|

EcoModding Apprentice

Join Date: Jun 2010

Location: New York

Posts: 239

Thanks: 0

Thanked 17 Times in 15 Posts

|

right you will have to daisy chain vacuum tapes off each TB runner for MAP sensor and power brake booster if vehicle has one .

getting nice even idle will be big problem , same issues as with motorcycle engines .

What I would do is try an either find if your vehicle has a IM that has longer, thinner runners version available or if not maybe you can add a spacer (depending on how its made, multiple parts) to length runner length a bit.

this will lower sweet spot more for low to mid TQ which should help in eco conditions if car isn't already optimized for it .

|

|

|

|

06-01-2012, 04:47 PM

06-01-2012, 04:47 PM

|

#13 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 710 Times in 458 Posts

|

Yah, that's kind of a ram air effect. Air inside the runners would be accelerated toward the cylinder by the action of the intake stroke, and when the intake valve closes, the moving air would then stop against the closed valve. This would raise pressure right at the intake valve, and would lower pumping losses as the intake valve opens again. Longer runners allow the air to achieve a higher velocity than shorter runners.

Gee, so ram air turns out to be good for ecomodding after all... But only if the ram air is past the throttle!  |

|

|

|

06-01-2012, 10:18 PM

06-01-2012, 10:18 PM

|

#14 (permalink)

|

|

Master EcoModder

Join Date: Jan 2012

Location: United States

Posts: 1,756

Thanks: 104

Thanked 407 Times in 312 Posts

|

Quote:

Originally Posted by t vago

|

I think that was more for throttle response. Valvetronic technically can have even better response, but the extra moving parts are not reliable and efficient at high rpm. |

|

|

|

06-01-2012, 10:37 PM

06-01-2012, 10:37 PM

|

#15 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Quote:

Originally Posted by t vago

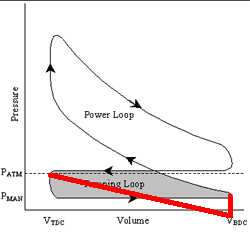

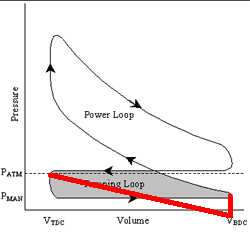

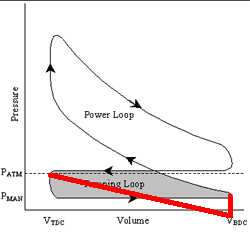

This will make the pumping loop look more like a triangle...

|

I wonder if this triangle would end up dipping lower to right side to make up for the lack of vacuum when the intake valve first opens to achieve the same cylinder vacuum when the intake valve closes.

If so, this would end up giving you the exact same pumping losses as with a single throttle body.

|

|

|

|

06-01-2012, 11:43 PM

06-01-2012, 11:43 PM

|

#16 (permalink)

|

|

The road not so traveled

Join Date: Jan 2010

Location: New Mexico

Posts: 680

Thanks: 18

Thanked 66 Times in 57 Posts

|

Quote:

Originally Posted by t vago

Yah, I'd be looking at a 20 mm throttle bore if I were to be doing this to my truck. To my knowledge, that's in the realm of lawn mowers and similar small engines.

The big problem with this arises from trying to adapt it to the existing engine electronics. There is no more reliable vacuum source from which to do speed-density tuning (MAP and IAT). MAF engines should not have this problem, though.

A secondary problem arises from implementing engine idle. That's pretty much independent of whether the engine uses MAF or speed-density.

A tertiary problem arises from powering vacuum-dependent accessories, like power brakes and cruise control.

|

Have all of the intakes pre throttles go to a single chamber the inlet to that chamber can have the MAF sensor.

They make an electric brake booster, it shouldn't be too hard to rig in as it is typically smaller than the vacuume based booster. |

|

|

|

06-01-2012, 11:46 PM

06-01-2012, 11:46 PM

|

#17 (permalink)

|

|

Master EcoModder

Join Date: Jan 2012

Location: United States

Posts: 1,756

Thanks: 104

Thanked 407 Times in 312 Posts

|

Quote:

Originally Posted by mechman600

I wonder if this triangle would end up dipping lower to right side to make up for the lack of vacuum when the intake valve first opens to achieve the same cylinder vacuum when the intake valve closes.

If so, this would end up giving you the exact same pumping losses as with a single throttle body. |

No vertical piece before compression. However, if there are less losses, then the temperature at the beginning of compression should be lower so the pressure is probably lower too. By how much is hard to say.

|

|

|

|

06-02-2012, 01:56 PM

06-02-2012, 01:56 PM

|

#18 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 710 Times in 458 Posts

|

Quote:

Originally Posted by mechman600

I wonder if this triangle would end up dipping lower to right side to make up for the lack of vacuum when the intake valve first opens to achieve the same cylinder vacuum when the intake valve closes.

If so, this would end up giving you the exact same pumping losses as with a single throttle body. |

Well, keep in mind that the right-most part of your line would never go below P(man).

The blue line represents would would happen, for a throttle that was just cracked (for instance, if part-throttle engine operation were attempted with too large a throttle body):

See how the blue line quickly drops from P(man) and drops almost to the bottom of the graph. This is because the piston is sucking in more air than the throttle can provide. As the piston slows down and goes to bottom dead center, the cracked throttle is able to provide enough air to lessen the vacuum.

This is how ITBs gained a reputation for having driveability problems, particularly with a lack of torque. At part-throttle operations just above idle, they actually do more pump work just to suck in air than with a normal single throttle/intake manifold setup. Worse yet, it's a non-linear function that describes how the pump work lessens as the throttle is progressively opened up. It becomes an engineering challenge to control throttle response at this point.

|

|

|

|

06-02-2012, 04:11 PM

06-02-2012, 04:11 PM

|

#19 (permalink)

|

|

...beats walking...

Join Date: Jul 2009

Location: .

Posts: 6,190

Thanks: 179

Thanked 1,525 Times in 1,126 Posts

|

...sounds like the inverse reason behind why Old Man Ferrari liked 12-cylinder race engines, because the smaller bores (though more of them) actually resulted in LOWER engine friction and "slung" mass at the higher RPM's that such engines could reach.

|

|

|

|

06-03-2012, 07:30 PM

06-03-2012, 07:30 PM

|

#20 (permalink)

|

|

Master EcoModder

Join Date: Jan 2012

Location: United States

Posts: 1,756

Thanks: 104

Thanked 407 Times in 312 Posts

|

Quote:

Originally Posted by t vago

Well, keep in mind that the right-most part of your line would never go below P(man).

The blue line represents would would happen, for a throttle that was just cracked (for instance, if part-throttle engine operation were attempted with too large a throttle body):

See how the blue line quickly drops from P(man) and drops almost to the bottom of the graph. This is because the piston is sucking in more air than the throttle can provide. As the piston slows down and goes to bottom dead center, the cracked throttle is able to provide enough air to lessen the vacuum. |

Thanks for the pretty picture

Valve timing would affect the effectiveness of this as well, of course.

If only we could move to continuous profile camshafts...they are mighty expensive to machine so I hear, but they give low friction high rpm operation, and even less pumping loss than Valvetronic/Valvematic/etc. at part load. Ferrari has them but has them set up more for optimal torque across the rev range, and I hear they have reliability issues due to wear.

|

|

|

|

|