09-04-2010, 06:30 PM

09-04-2010, 06:30 PM

|

#31 (permalink)

|

|

Pokémoderator

Join Date: Dec 2007

Location: Southern California

Posts: 5,864

Thanks: 439

Thanked 532 Times in 358 Posts

|

Hello -

Is "lots of DFCO" a good place for a PCV oil catch can thingy? Or will it "not help much"?

CarloSW2

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

09-09-2010, 01:01 PM

09-09-2010, 01:01 PM

|

#32 (permalink)

|

|

Legend in my own mind

Join Date: Apr 2008

Location: Homestead, Fl.

Posts: 927

Thanks: 2

Thanked 14 Times in 13 Posts

|

With regards to my scangauge not reading 9999 when Engine Off Coasting;

As mentiuoned earlier, it is likely a problem with my scangauge ... After reading through this I changed one of my settings to read GPH and when the car is off and the key is in the ON position I still reads .02 GPH usage instead of 0.00 when the car engages the DFCO while cruising in gear ...

Oh well, at least I found my problem ...

Thanks guys ...

__________________

Thx NoCO2; "The biggest FE mod you can make is to adjust the nut behind the wheel"

I am a precisional instrument of speed and aeromatics

If your knees bent in the opposite direction......what would a chair look like???

|

|

|

|

09-09-2010, 01:08 PM

09-09-2010, 01:08 PM

|

#33 (permalink)

|

|

Master EcoModder

Join Date: Jul 2010

Location: Belgium

Posts: 4,683

Thanks: 178

Thanked 652 Times in 516 Posts

|

Quote:

Originally Posted by trikkonceptz

Oh well, at least I found my problem ...

|

Maybe if you set the cutoff value a bit higher it'll work ?

__________________

Strayed to the Dark Diesel Side

|

|

|

|

09-09-2010, 02:00 PM

09-09-2010, 02:00 PM

|

#34 (permalink)

|

|

Pokémoderator

Join Date: Dec 2007

Location: Southern California

Posts: 5,864

Thanks: 439

Thanked 532 Times in 358 Posts

|

trikkonceptz -

Quote:

Originally Posted by trikkonceptz

With regards to my scangauge not reading 9999 when Engine Off Coasting;

As mentiuoned earlier, it is likely a problem with my scangauge ... After reading through this I changed one of my settings to read GPH and when the car is off and the key is in the ON position I still reads .02 GPH usage instead of 0.00 when the car engages the DFCO while cruising in gear ...

Oh well, at least I found my problem ...

Thanks guys ...

|

Can you do me a favor and tell me what your RPM and MAP are when the car is off and the key is in the ON position? The reason I ask is that when my key is in the ON position, I still see 61 RPM. That leads me to believe that the SG thinks the engine is still running, however slightly. The 61 RPM could be an error in the sensor at 0 RPM (likely), or some kind of failsafe non-zero value reported by the ECU/PCM to avoid divide-by-zero errors (not likely, otherwise why not 1 RPM for that case).

CarloSW2 |

|

|

|

09-09-2010, 02:19 PM

09-09-2010, 02:19 PM

|

#35 (permalink)

|

|

Legend in my own mind

Join Date: Apr 2008

Location: Homestead, Fl.

Posts: 927

Thanks: 2

Thanked 14 Times in 13 Posts

|

Quote:

Originally Posted by cfg83

trikkonceptz -

Can you do me a favor and tell me what your RPM and MAP are when the car is off and the key is in the ON position? The reason I ask is that when my key is in the ON position, I still see 61 RPM. That leads me to believe that the SG thinks the engine is still running, however slightly. The 61 RPM could be an error in the sensor at 0 RPM (likely), or some kind of failsafe non-zero value reported by the ECU/PCM to avoid divide-by-zero errors (not likely, otherwise why not 1 RPM for that case).

CarloSW2

|

Will do, I will try it on my way home and I will post my results as soon as I can ...

__________________

Thx NoCO2; "The biggest FE mod you can make is to adjust the nut behind the wheel"

I am a precisional instrument of speed and aeromatics

If your knees bent in the opposite direction......what would a chair look like???

|

|

|

|

|

The Following User Says Thank You to trikkonceptz For This Useful Post:

|

|

09-09-2010, 08:49 PM

09-09-2010, 08:49 PM

|

#36 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

I would talk to Linear Logic about your display errors. It sounds to me like a problem with the conversions of the raw data into decimal values.

When I tune an ECM I normally program in aggressive DFCO values as possible. DFCO does create a lot of engine braking, though it is possible to reduce this down to a minimum by setting the DFCO IAC steps to the maximum value of 255. This reduces the engine vacuum during coast-down DECEL, but be aware that if you have a manifold pressure sensor it is often used as one of the threshold parameters for the DFCO logic routine. That means that if you reduce engine vacuum too much after DFCO is initiated, then it will just kick back out of DFCO. There is a hysteresis that will keep DFCO from pulsing on and off.

Also, there is a parameter to unlock the TCC when DFCO is activated, which will reduce the amount of time that you can keep DFCO on. I like to keep the TCC locked and the lower limit TCC threshold as low as possible to prevent unlocking during coast-down.

I always run filters on my PCV system, but during DFCO most of the oiling will be coming from the intake valve guides and past the piston rings.

I will try to post some of the calibration and code for DFCO that is used in my 1991 Chevy truck.

__________________

#####################################

|

|

|

|

09-09-2010, 09:07 PM

09-09-2010, 09:07 PM

|

#37 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

DFCO strategy

This is about 95% of the calibration and algorithm concerning DFCO in one particular ECM.

Quote:

;---------------------------------------------

; DFCO DECELERATION FUEL CUT-OFF 4 LINE TABLE

;---------------------------------------------

LD2E3 FCB 56 ; 1400 RPM, FUEL CUT-OFF, UPPER LIMIT 2500

LD2E4 FCB 40 ; 1000 RPM, FUEL CUT-OFF, LOWER LIMIT 1200

LD2E5 FCB 18 ; 18 MPH, FUEL CUT-OFF, UPPER LIMIT

LD2E6 FCB 15 ; 15 MPH, FUEL CUT-OFF, LOWER LIMIT

LD2E7 FCB 8 ; 22.5 Kpa, S/D MAP DECEL FUEL Cut-Off Thresh, Lower ((X * 0.3125)+20)

LD2E8 FCB 64 ; 40.0 Kpa, S/D MAP DECEL FUEL Cut-Off Thresh, Upper ((X * 0.3125)+20)

LD2E9 FCB 255 ; 3188 RPM/12.5, RPM DIFF DECREMENT (decel rate) THRESH To disable DFCO

LD2EA FCB 255 ; 79.7 Kpa, S/D MAP DIFF INCREMENT THRESH to disable DFCO (X * 0.3125)

LD2EB FDB 0464 ; 7.07 msec, Fuel PW IF EXITING DFCO BY RPM, OR Park/Neut PW * 65.536

LD2ED FCB 160 ; 2 sec REQ FOR DFCO

LD2EE FCB 32 ; 400 Msec AFTER DFCO FOR BPW

LD2EF FCB 240 ; 3 secs MIN TIME BETWEEN DFCO (Sec * 80)

LD2F0 FCB 14 ; 5% MAX TPS FOR DECEL FUEL Cut Off

LD2F1 FCB 96 ; 0.375 MULTIPLIER FOR BPW IN DFCO EVERY 12.5 msec LOOP (sub'd, not mult)

LD2F2 FCB 128 ; 75c/167f, LINEAR COOLANT THRESHOLD TO DISABLE DFCO

__________________________________________

LD5D3 FDB 40 ; 40 Steps, ADDED TO IAC WHEN DFCO IN EFFECT (single byte)

__________________________________________

D87A: LD87A LDAA L0021 ; GET LINEAR COOLANT

D87C: CMPA LD2F2 ; COMPARE A TO (75c/167f, DISABLE DFCO BELOW COOLANT THRESHOLD)

D87F: BCC LD884 ; IF COOLANT GT THRESH, BRANCH TO $D884 (DO DFCO CHECKS)

D881: JMP LD946 ; JUMP TO $D946 (TURN DFCO OFF)

;---------------------------------

D884: LD884 LDAA L000F ; GET STATUS, b4=1= (IN PARK/NEUT)

D886: BITA #$10 ; TEST b4 (IN PARK/NEUT?)

D888: BNE LD8B5 ; IF b4 BRANCH TO $D8B5 (EXIT FUEL DFCO ROUTINE)

D88A: LDAB L0009 ; GET STATUS WORD

D88C: BITB #$24 ; TEST b5,b2

D88E: BNE LD89F ; IF b5,b2 BRANCH TO $D89F

D890: LDAA L0049 ; GET CURRENT TPS

D892: CMPA LD2F0 ; COMPARE TO 5% MAX TPS FOR DECEL FUEL Cut Off

D895: BCS LD89F ; IF TPS LT 5% BRANCH TO $D89F (SKIP DFCO UPDATE)

D897: LDAA L0003 ; GET STATUS WORD FOR DFCO

D899: ORAA #$10 ; SET b4, IN FUEL DFCO

D89B: STAA L0003 ; UPDATE STATUS WORD FOR DFCO

D89D: BRA LD8CB ; BRANCH ALWAYS TO $D8CB

;---------------------------------

D89F: LD89F LDAA L0020 ; GET OLD RPM/12.5

D8A1: SUBA L001F ; SUBTRACT FILTERED RPM/12.5 (OLD - CURRENT FILTERED)

D8A3: BCS LD8AA ; IF RPM INCREASING, BRANCH TO $D8AA

D8A5: CMPA LD2E9 ; COMPARE TO RPM/12.5, 3188 RPM DIFF To disable DFCO (Decel rate)

D8A8: BHI LD8B5 ; IF DIFF RPM GT CALIBRATION, BRANCH TO $D8B5 (EXIT DFCO ROUTINE)

D8AA: LD8AA BITB #$48 ; TEST b6 & b3, L0009

D8AC: BNE LD8E2 ; IF b6,b3, BRANCH TO $D8E2

D8AE: LDAA L0032 ; GET DIFF MAP (S/D MAP)

D8B0: CMPA LD2EA ; COMPARE TO 100 kpa MAP INCREASE TO DISABLE DFCO

D8B3: BLS LD8D0 ; IF MAP INCREASE LT THRESH TO DISABLE, BRANCH TO $D8D0 (CONTINUE DFCO CHECKS)

;=================================================

; HERE TO EXIT DECEL FUEL CUT/0FF (DFCO)

;=================================================

D8B5: LD8B5 LDAA L00A0 ; GET POST DFCO TIMER

D8B7: BEQ LD8CB ; BRANCH IF TIMER = 0

D8B9: LDD L0096 ; GET BPW, ASYN

D8BB: ADDD LD2EB ; ADD FUEL PULSE WHEN EXITING DFCO, 7.07 Msec BY RPM < OR Park/Neut

D8BE: BCC LD8C3 ; BRANCH IF NO OVERFLOW

D8C0: LDD #$7FFF ; GET USE MAX VALUE

D8C3: LD8C3 STD L0096 ; UPDATE BPW, ASYN

D8C5: LDAA L000D ; GET STATUS WORD

D8C7: ORAA #$80 ; SET b7

D8C9: STAA L000D ; UPDATE STATUS WORD

D8CB: LD8CB CLR L00A0 ; CLEAR POST DFCO TIMER

D8CE: BRA LD937 ; BRANCH ALWAYS TO $D937

;---------------------------------

D8D0: LD8D0 LDAA L0026 ; GET S/D MAP

D8D2: LDAB L0008 ; GET STATUS WORD FOR DFCO

D8D4: CMPA LD2E7 ; COMPARE MAP TO DFCO MAP Thresh, Lower, 22.5 Kpa

D8D7: BCS LD8E2 ; IF S/D MAP LT DFCO MAP THRESH LOWER, BRANCH TO $LD8E2 (DO OTHER CHECKS)

D8D9: BITB #08 ; TEST b3, (IN DFCO ALREADY?)

D8DB: BEQ LD937 ; IF NOT b3, BRANCH TO $LD937 (TURN DFCO OFF)

D8DD: CMPA LD2E8 ; COMPARE MAP TO DFCO MAP Thresh, Upper, 45 Kpa

D8E0: BCC LD937 ; IF MAP GT DFCO MAP THRESH UPPER, BRANCH TO $LD937 (TURN DFCO OFF)

;=================================================

; Limits for FUEL CUT-OFF In decel (DFCO)

; 1000/1400 RPM 4-LINE TABLE 15/18 MPH

;=================================================

D8E2: LD8E2 LDX #$D2E3 ; POINT TO 4 LINE TABLE DFCO PARAMS

D8E5: LDAB L0008 ; GET STATUS WORD

D8E7: BITB #$08 ; TEST BIT 3 (IN DFCO ALREADY?)

D8E9: BEQ LD8EC ; IF NOT B3, BANCH TO $LD8EC (NO DFCO, CHECK RPM LIMIT UPPER)

D8EB: INX ; INCREMENT REGISTER X BY ONE (IN DFCO, CHECK RPM LIMIT LOWER)

D8EC: LD8EC LDAA L001C ; GET RPM/25

D8EE: CMPA 0,X ; COMPARE RPM TO 1000/1400 RPM HYSTERESIS

D8F0: BLS LD8B5 ; IF RPM LT 1000/1400 LIMIT, (EXIT DFCO)

D8F2: LDAA L0034 ; GET FILTERED VSS MPH/1

D8F4: CMPA 2,X ; COMPARE TO 15/18 MPH

D8F6: BCS LD8B5 ; IF MPH LT 15/18 MPH, (EXIT DFCO)

;=================================================

; CHECK DECEL FUEL CUT/OFF TIMER (DFCO)

;=================================================

D8F8: LDAA L00A1 ; GET DFCO TIMER

D8FA: BNE LD934 ; IF NOT TIMED OUT, BRANCH TO $D934 (DECREMENT TIMER, TURN DFCO OFF)

D8FC: LDAB LD2EF ; GET CALIB 3 Secs MIN BETWEEN DFCO

D8FF: LDAA L0003 ; GET STATUS WORD

D901: BITA #$10 ; TEST b4, (IN FUEL DFCO?)

D903: BEQ LD90B ; IF NOT b4, BRANCH TO $D90B

D905: ANDA #$EF ; CLEAR b4

D907: STAA L0003 ; UPDATE STATUS WORD

D909: STAB L009F ; UPDATE BETWEEN DECEL FUEL C/0 TIMER

D90B: LD90B CMPB L009F ; COMPARE TO BETWEEN DECEL FUEL C/0 TIMER

D90D: BLS LD914 ; IF LOWER OR SAME, BRANCH TO $D914

D90F: INC L009F ; INCREASE DECEL FUEL C/0 TIMER

D912: BRA LD946 ; BRANCH ALWAYS TO $D946 (TURN DFCO OFF)

;---------------------------------

D914: LD914 LDAB L0008 ; GET STATUS WORD

D916: ORAB #8 ; SET b3,

D918: STAB L0008 ; UPDATE STATUS WORD

D91A: LDAA LD2EE ; GET CALIBRATION, 400msec AFTER DFCO FOR BPW

D91D: STAA L00A0 ; UPDATE POST DFCO TIMER (AFTER DFCO TIL PW)

D91F: LDAA L000D ; GET STATUS WORD

D921: ORAA #$10 ; SET b4, (DECEL ENLEANMENT IN EFFECT)

D923: STAA L000D ; UPDATE STATUS WORD

D925: LDAA L009E ; GET DECEL FUEL MULTIPLIER

D927: SUBA LD2F1 ; SUBTRACT ( A - CALIBRATION, 10.2% MULT FOR BPW IN DFCO)

D92A: BCC LD92D ; IF DECEL FUEL MULT GT CALIBRATION, BRANCH TO $D92D (DO NOT RESET MULT)

D92C: CLRA ; CLEAR A REGISTER (RESET DECEL MULTIPLIER TO ZERO)

D92D: LD92D STAA L009E ; UPDATE DECEL FUEL MULTIPLIER

D92F: JSR LD839 ; GOSUB $D839 (POINT TO BPW SYNC, AND DO CALC)

;---------------------------------

D932: BRA LD9A4 ; BRANCH ALWAYS TO $D9A4

D934: LD934 DECA ; DECREMENT DECEL FUEL TIMER

D935: BRA LD93A ; BRANCH ALWAYS TO $D93A

;---------------------------------

D937: LD937 LDAA LD2ED ; GET 2 Sec REQ FOR DFCO

D93A: LD93A STAA L00A1 ; DECEL FUEL CUT/OFF TIMER

D93C: CLR L009F ; CLEAR BETWEEN DECEL FUEL CUT/OFF TIMER

D93F: LDAA L00A0 ; GET POST DFCO TIMER

D941: BEQ LD946 ; IF TIMED OUT, BRANCH TO $D946 (SKIP DECREASE POST DFCO TIMER)

D943: DEC L00A0 ; DECREASE POST DFCO TIMER

D946: LD946 LDAA L0008 ; GET STATUS WORD

D948: ANDA #$F7 ; CLEAR b3 (TURN DFCO OFF)

D94A: STAA L0008 ; UPDATE STATUS WORD

D94C: LDAA #255 ; LOAD A REGISTER WITH MAX VALUE (255)

D94E: STAA L009E ; UPDATE DECEL FUEL MULTIPLIER

D950: LDD L004D ; GET FILTERED TPS (TWO BYTES) INTO D

D952: ASLB ; REGISTER Bx2

D953: ADCA #0 ; REGISTER A ROUND OFF

D955: BCC LD958 ; IF NO OVERFLOW, BRANCH TO $D958

D957: DECA ; DECREMENT A REGISTER

D958: LD958 SUBA L0049 ; SUBTRACT (A FILTERED TPS - CURRENT TPS)

D95A: BCS LD99E ; IF A LT CURRENT TPS, BRANCH TO $D99E (TPS INCREASING, TURN DECEL OFF)

D95C: CMPA LD2E0 ; COMPARE DIFF TPS TO 1% TPS, DECEL ENLEAN INCREMENT THRESH

D95F: BLS LD99E ; IF DIFF TPS LT 1% DECEL THRESH, BR TO $D99E(NOT DECREASING ENOUGH FOR DECEL)

D961: LDD L002F ; GET FILTERED MAP (TWO BYTES) INTO D

D963: ASLB ; REGISTER Bx2

D964: ADCA #0 ; REGISTER A ROUND

D966: BCC LD969 ; IF NO OVERFLOW, BRANCH TO $D969 (DON'T DECREMENT A)

D968: DECA ; DECREMENT A REGISTER

D969: LD969 SUBA L0026 ; SUBTRACT (A, FILTERED MAP - CURRENT S/D MAP)

D96B: BCS LD99E ; IF A LT S/D MAP, BRANCH TO $D99E (MAP INCREASING, TURN DECEL OFF)

D96D: CMPA LD2E1 ; COMPARE DIFF MAP TO 2.5 Kpa S/D MAP DIFF DECREMENT THRESH FOR DECEL ENLEAN

D970: BLS LD99E ; IF DIFF LT 2.5 THRESH, BRANCH TO $D99E (NOT DECREASING ENOUGH FOR DECEL)

D972: LDAB LD2E2 ; GET 0.375 ENLEAN MAP FACTOR (Mult .375 * DIFF MAP for calc)

D975: MUL ; MULTIPLY A x B = D

D976: LDAB L009D ; GET DECEL COOLANT FACTOR

D978: MUL ; MULTIPLY A x B = D

D979: ASLD ; REGISTER Dx2

D97A: BCS LD982 ; IF OVERFLOW, BRANCH TO $D982

D97C: ASLD ; REGISTER Dx2

D97D: BCS LD982 ; IF OVERFLOW, BRANCH TO $D982

D97F: ASLD ; REGISTER Dx2

D980: BCC LD984 ; IF NO OVERFLOW, BRANCH TO $D984 (DON'T USE MAX VALUE)

D982: LD982 LDAA #255 ; USE MAX VALUE

D984: LD984 NEGA ; INVERT

D985: BEQ LD99E ; IF ZERO, BRANCH TO $D99E (TURN DECEL ENLEAN OFF)

D987: LDAB L000D ; GET STATUS WORD

D989: ORAB #$10 ; SET b4, (TURN ON DECEL ENLEAN)

D98B: STAB L000D ; UPDATE STATUS WORD

D98D: STAA L0058 ; UPDATE PROP DURATION, Secs

D98F: LDX #L0096 ; POINT TO L0096 & L0097 BPW, ASYNC

D992: JSR LFBB9 ; GOSUB $FBB9 (FUEL OUT ROUTINE)

;------------------------------------

D995: STD L0096 ; UPDATE L0096 & L0097, BPW, ASYNC

D997: LDAA L0058 ; GET PROP DURATION, SECs

D999: JSR LD839 ; GOSUB $D839 (POINT TO BPW SYNC, AND DO CALC)

;------------------------------------

D99C: BRA LD9A7 ; BRANCH ALWAYS TO $D9A7

;------------------------------------

D99E: LD99E LDAA L000D ; GET STATUS WORD

D9A0: ANDA #$EF ; CLEAR b4 (TURN DECEL ENLEAN OFF)

D9A2: STAA L000D ; UPDATE STATUS WORD

D9A4: LD9A4 LDX #L00AB ; GET L00AB & L00AC BPW, SYNC INTO X

D9A7: LD9A7 LDAA L00B2 ; GET BATTERY COMPENSATION MULTIPLIER INTO A

D9A9: JSR LFBB9 ; GOSUB $FBB9 (FUEL OUT ROUTINE)

;------------------------------------

|

__________________

#####################################

|

|

|

|

09-10-2010, 10:47 AM

09-10-2010, 10:47 AM

|

#38 (permalink)

|

|

Legend in my own mind

Join Date: Apr 2008

Location: Homestead, Fl.

Posts: 927

Thanks: 2

Thanked 14 Times in 13 Posts

|

OK as requested I checked my RPM and MAP data while Engine Off Coasting.

My RPM's drop to 0 once the engine shuts off, as far as the MAP reading .... well that must not report through my OBT port because it remained blank with no reading whether the car is running or OFF. So sorry about that one ..

The only one that still puzzles me is the GPM that reads .02 while the car is off and key is on. I have to assume that is the only thing keeping the mileage from going to 9999 while EOCing.

Good luck with your quirky SG ..lol

__________________

Thx NoCO2; "The biggest FE mod you can make is to adjust the nut behind the wheel"

I am a precisional instrument of speed and aeromatics

If your knees bent in the opposite direction......what would a chair look like???

|

|

|

|

09-10-2010, 11:54 AM

09-10-2010, 11:54 AM

|

#39 (permalink)

|

|

oldschool

Join Date: May 2010

Location: Illinois

Posts: 184

Thanks: 21

Thanked 35 Times in 25 Posts

|

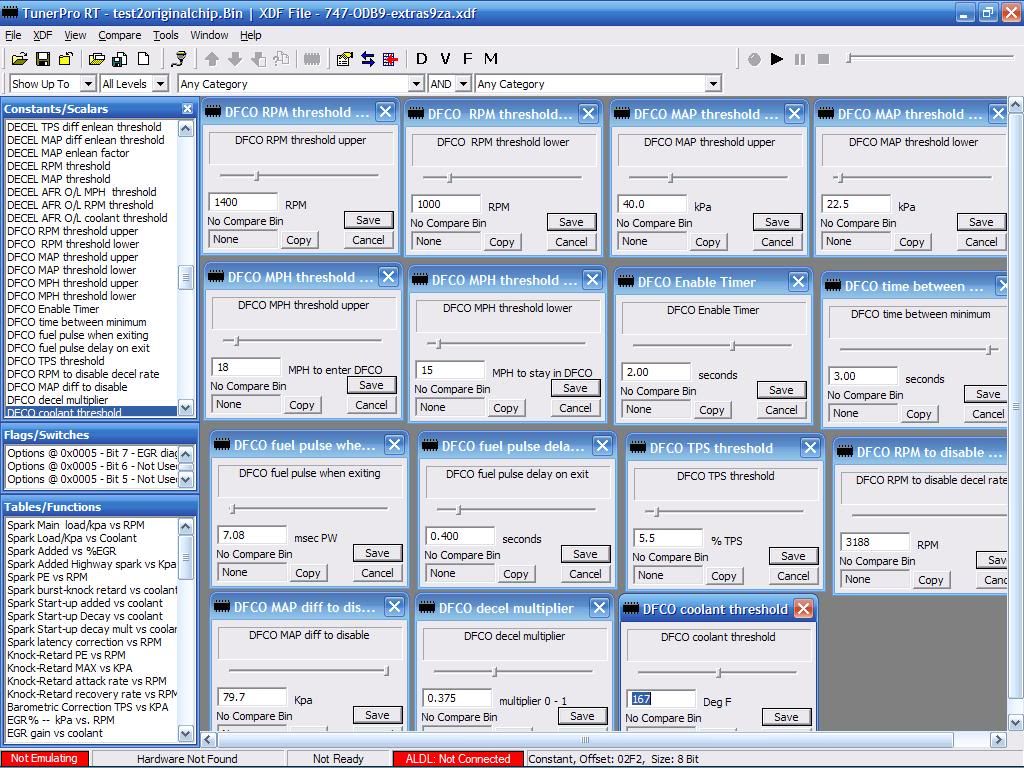

Here is a screen-shot of some of the (stock) DFCO calibrations on my 1991 Chevy Truck.

link for larger photo:

http://i702.photobucket.com/albums/w...FCOscreen1.jpg

Note that the factory calibrations shown are not very aggressive at all, and during normal driving conditions it is rare for DFCO to engage.

Also, DFCO and DECEL-enleanment are two completely different things.

DECEL-enleanment commands leaner than stoich AFRs during most deceleration conditions, but only functions when in open-loop mode.

Though it is very wasteful of fuel, closed-loop mode maintains a 14.6:1 AFR during deceleration conditions unless DFCO is engaged.

__________________

#####################################

|

|

|

|

|

The Following User Says Thank You to Olympiadis For This Useful Post:

|

|

09-13-2010, 10:04 PM

09-13-2010, 10:04 PM

|

#40 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

no map sensor ?

...."OK as requested I checked my RPM and MAP data while Engine Off Coasting.

My RPM's drop to 0 once the engine shuts off, as far as the MAP reading .... well that must not report through my OBT port because it remained blank with no reading whether the car is running or OFF. So sorry about that one .."....

the car may not be a speed density system

it may use a MAF sensor as the primary load sensor

in which case

it would not report MAP value in

Generic OBD2 which is all you get with Scangauge2

|

|

|

|

|