03-22-2017, 08:32 AM

03-22-2017, 08:32 AM

|

#31 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,032

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Quote:

Originally Posted by teoman

I had the idea that the EGR valve might be a good place to inject the steam.

|

IIRC in spark-ignited engines the EGR is actually more functional than in Diesel engines, since it allows a small part of the crude hydrocarbons usually released along the exhaust stream to recirculate. But presumably if you can make it run leaner enough to decrease the HC emissions to a minimum the EGR valve seems to be a good spot to inject the steam, since the it would be able to provide a cooling effect to the pistons in a way similar to what a richer mixture would.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

03-22-2017, 08:47 AM

03-22-2017, 08:47 AM

|

#32 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 710 Times in 458 Posts

|

Quote:

Originally Posted by teoman

Why would it fill up with water?

|

For the same reason that it's possible to boil water in a paper cup.

That piping you're using is not going to be at a uniform temperature. At the very least, due to the constant flow of air past your EGR entry point, that is going to be at intake air temperature. The steam you create is going to condense downstream of the boiling point where the copper pipe is wrapped around your exhaust manifold, and unless you managed to place your exhaust above your intake, your piping will eventually fill up with hot water.

But, hey, I could be wrong. |

|

|

|

|

The Following User Says Thank You to t vago For This Useful Post:

|

|

03-22-2017, 09:40 AM

03-22-2017, 09:40 AM

|

#33 (permalink)

|

|

Master EcoModder

Join Date: Jan 2017

Location: Istanbul

Posts: 1,245

Thanks: 65

Thanked 225 Times in 186 Posts

|

Unfortunately I do not fully follow.

The my idea is to keep all copper in tontact with exhaust manifold, with just the ends pointing slightly up (about 5 cm, a number I generated from my ass). So all copper is about exhaust temperature.

The input side has about 10 cm of silicone hose (same method of specification generation). The output side has about 30-40 cm of silicone hose that has an ID of 0.8mm. Not much water will gather there. I have such hose coming to me for a soft robotics project. So i thought why not. If it is a small ID, the steam will exit with a high velocity helping mixing. The length will give a bit of resistance to the flow, so i can increase pressure ever so slightly, raising the boiling temp of the water.

I just do not see where the water that will accumulate in the pile will come from. The amount of water as we calculated above is about 2.4 liters per hour.

If i introduce air flow to the pipe, the expansion of the steam will not be unidirectional, it will also try to expand in the direction where i introduce the said airflow.

Once the car stops, there will be steam in the silicone hose (negligeable) and some in the copper pipe. Which will condense when the car cools down. But it will re evaporize when engine starts. We are still talking about just a couple of drops. If it were not for the corrosive effect of the water, the 2 drops would in fact be beneficial to the functioning of the system because once it reevaporates, the system is recharged with steam which will be pushed to the intake with the next injector pulse. (Otherwise the first injector pulse generates steam which displaces the hot air in the pipe and hose in to the intake).

But please correct me if i am wrong.

.

|

|

|

|

03-22-2017, 09:55 AM

03-22-2017, 09:55 AM

|

#34 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 710 Times in 458 Posts

|

Quote:

Originally Posted by teoman

Unfortunately I do not fully follow.

The my idea is to keep all copper in tontact with exhaust manifold, with just the ends pointing slightly up (about 5 cm, a number I generated from my ass). So all copper is about exhaust temperature.

The input side has about 10 cm of silicone hose (same method of specification generation). The output side has about 30-40 cm of silicone hose that has an ID of 0.8mm. Not much water will gather there. I have such hose coming to me for a soft robotics project. So i thought why not. If it is a small ID, the steam will exit with a high velocity helping mixing. The length will give a bit of resistance to the flow, so i can increase pressure ever so slightly, raising the boiling temp of the water.

I just do not see where the water that will accumulate in the pile will come from. The amount of water as we calculated above is about 2.4 liters per hour.

If i introduce air flow to the pipe, the expansion of the steam will not be unidirectional, it will also try to expand in the direction where i introduce the said airflow.

Once the car stops, there will be steam in the silicone hose (negligeable) and some in the copper pipe. Which will condense when the car cools down. But it will re evaporize when engine starts. We are still talking about just a couple of drops. If it were not for the corrosive effect of the water, the 2 drops would in fact be beneficial to the functioning of the system because once it reevaporates, the system is recharged with steam which will be pushed to the intake with the next injector pulse. (Otherwise the first injector pulse generates steam which displaces the hot air in the pipe and hose in to the intake).

But please correct me if i am wrong.

.

|

Good luck with your apparatus. I look forward to seeing it working. |

|

|

|

03-22-2017, 09:56 AM

03-22-2017, 09:56 AM

|

#35 (permalink)

|

|

Master EcoModder

Join Date: Jan 2017

Location: Istanbul

Posts: 1,245

Thanks: 65

Thanked 225 Times in 186 Posts

|

Quote:

Originally Posted by cRiPpLe_rOoStEr

IIRC in spark-ignited engines the EGR is actually more functional than in Diesel engines, since it allows a small part of the crude hydrocarbons usually released along the exhaust stream to recirculate. But presumably if you can make it run leaner enough to decrease the HC emissions to a minimum the EGR valve seems to be a good spot to inject the steam, since the it would be able to provide a cooling effect to the pistons in a way similar to what a richer mixture would.

|

Diesels can run at whatever AFR they please. Gasoline fueled engines have to maintain a constant air to fuel (or oxygen to fuel) ratio. If you push in less o2 by means of pumping gas with no o2 (exhaust) then you can inject less fuel when power is not needed. So EGR has a bit of an advantage to control emissions and it can have a significant effect on fuel consumption.

I like that injection point. However looking at random pictures of my fancy intake manifold, it does not seem to mix uniformally with the intake air. But i could be completely wrong.

Last edited by teoman; 03-22-2017 at 10:03 AM..

|

|

|

|

03-24-2017, 03:00 AM

03-24-2017, 03:00 AM

|

#36 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,032

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Quote:

Originally Posted by teoman

Diesels can run at whatever AFR they please. Gasoline fueled engines have to maintain a constant air to fuel (or oxygen to fuel) ratio.

|

As long as there is a provision to cool the piston, a gasser can also run leaner at the expense of higher NOx emissions. |

|

|

|

03-25-2017, 05:40 AM

03-25-2017, 05:40 AM

|

#37 (permalink)

|

|

Master EcoModder

Join Date: Jan 2017

Location: Istanbul

Posts: 1,245

Thanks: 65

Thanked 225 Times in 186 Posts

|

Quote:

Originally Posted by cRiPpLe_rOoStEr

As long as there is a provision to cool the piston, a gasser can also run leaner at the expense of higher NOx emissions.

|

Water is supposed to help with the NOx problem. |

|

|

|

03-25-2017, 09:20 AM

03-25-2017, 09:20 AM

|

#38 (permalink)

|

|

Master EcoModder

Join Date: Jan 2017

Location: Istanbul

Posts: 1,245

Thanks: 65

Thanked 225 Times in 186 Posts

|

I am sourcing more materials.

Come to think of this, i may not be using a 100 psi bilge pump but a much cheaper windshield washer pump. I do not need the high pressure as atomization (small water droplets in this case, why they call it that i have no idea as it does not have anything to do with any fuel injector) will not play a part on the injector frontier. The vaporization will take care of that.

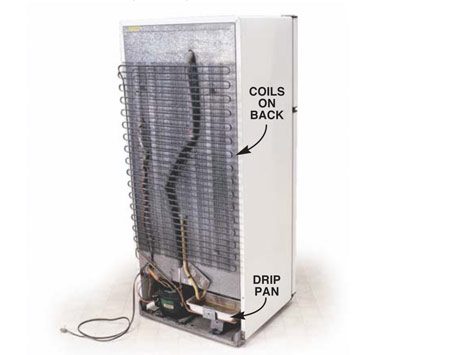

I had an old fridge that i discarded, but i saved some components for later on. I have the aluminium coil in the back that i intend on using for this project.

Will heat kill it off? |

|

|

|

03-25-2017, 02:28 PM

03-25-2017, 02:28 PM

|

#39 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,032

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Quote:

Originally Posted by teoman

Water is supposed to help with the NOx problem.

|

It does help with the NOx issue. |

|

|

|

03-26-2017, 07:01 AM

03-26-2017, 07:01 AM

|

#40 (permalink)

|

|

Master EcoModder

Join Date: Jan 2017

Location: Istanbul

Posts: 1,245

Thanks: 65

Thanked 225 Times in 186 Posts

|

I found another paper.

"In this study, the effects of steam injection at different injection rates on the evaluations of performance parameters and emissions of a gasoline engine have been investigated. Electronically controlled steam injection method has been used to inject the steam into the engine. The optimum steam ratio has been determined as 20% of fuel mass (S20) in terms of performance and emission parameters. Steam injected gasoline engine has been modeled by using zero-dimensional two-zone combustion model for optimum steam ratio at full load condition. The obtained results have been compared with conventional gasoline engine in terms of performance and NO, CO, CO2, HC emissions. The results of theoretical combustion model agree with experimental data quite well. In the experimental results, it is seen that the engine torque and the effective power increase up to 4.65% at 3200 rpm, specific fuel consumption reduces up to 6.44% at 2000 rpm. There is 40% average reduction in NO emissions at 2800 rpm and it is 31.5% in HC emissions at 2000 rpm. "

The calculated mass more or less agrees with our previous calculations.

https://www.researchgate.net/publica...gnition_engine

Steam has been obtained by means of exhaust waste heat from waste heat boiler. Steam in the waste heat boiler, which is kept in the form of saturated water with conditions of 3 bar and 133.5 C, was injected with injectors which are positioned at the back of intake valve in the manifold.

I wonder how much of this due to the increase in temperature and how much is due to the water.

Anyhow, it appears that %6 is the maximum improvement i can expect from this system which is not bad at all.

Last edited by teoman; 03-26-2017 at 07:52 AM..

|

|

|

|

|