naturalextraction, Thanks for your thread!!!

I have learned a ton from you and your project. Keep up the great work and I hope you will be back here with more information?

Because of you I have now started building a waste solvent system on my Talon project. I have over 500 gallons of free waste solvent for my testing.

Most of my waste solvent is made up of Toluene, around 60 to 75 %. So I'm building a pre-heating system. After studying the Honda Mc Laren F1 turbo race cars of the mid to late 80's I decided to run my IAT temps around 158*F and fuel temps around 176*F for fuel atomization? These temps will change once I start testing based on my waste solvent system will only make up 25% or less of total fuel mass?

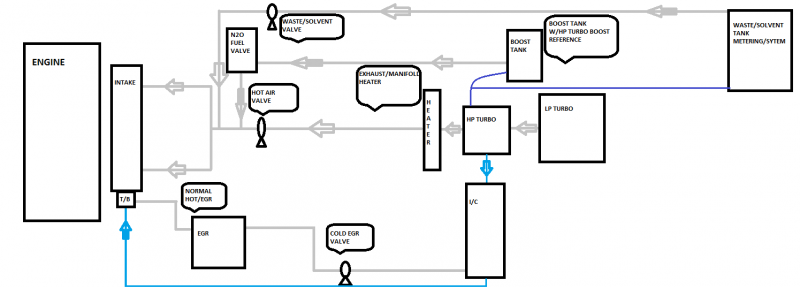

My new Hot/Cold EGR, Waste Solvent Flow Chart.

Modes:

1)Normal. Both systems disabled

2)High Heat, Light Load

3)Hot EGR only, Light to Medium Load

4)Hot EGR, High Heat, Light Load

5)Cold EGR, Light to Medium Load

6)Normal Waste Solvent Light Load

7)High Heat, Waste Solvent, Light Load

8)Hot EGR Waste Solvent, Light Load

9)Hot EGR, High Heat, Waste solvent, Light Load

10)Cold EGR, High Heat, Waste Solvent, Light Load

11)Cold EGR, Waste Solvent, High to Medium Load

12)Boost Tank, Extreme High Load

Anyway keep us informed on your project!!!