11-07-2021, 08:37 PM

11-07-2021, 08:37 PM

|

#151 (permalink)

|

|

Master EcoModder

Join Date: Nov 2020

Location: The Pas, Manitoba

Posts: 319

Thanks: 427

Thanked 147 Times in 113 Posts

|

4 lug, 100mm bolt pattern. I think that’s 4/100 PCD? Hm. I decided to cancel on the purchase as the tires are really old. Would rather just stick with free options for now. I figure I’ll probably end up using the 13s as they have brand new tires.

Agreed on safety. I keep getting obsessed with a e-trike project, but the lack of weight makes such a ride height really sketchy. You’re forced to go low, and that means poor viz. The weight of the FUV would likely make it more stable. Single wheel drive is definitely suboptimal, but as I’m the guy to build rather than buy, it’s my best option. Is the FUV 2WD?

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-07-2021, 09:53 PM

11-07-2021, 09:53 PM

|

#152 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,340

Thanks: 8,346

Thanked 9,110 Times in 7,523 Posts

|

I'm surprised, I thought Hondas were on 104mm, 110mm or something odd. That's the same as VWSuperbeetle, Type III and Golf. The next relevant items are bolt diameter (12mm?) and offset.

145/65-15 -- 22.42" (569.5) 155-50/15 -- 21.1 (536)

https://www.tacomaworld.com/tirecalc...5r15-155-50r15

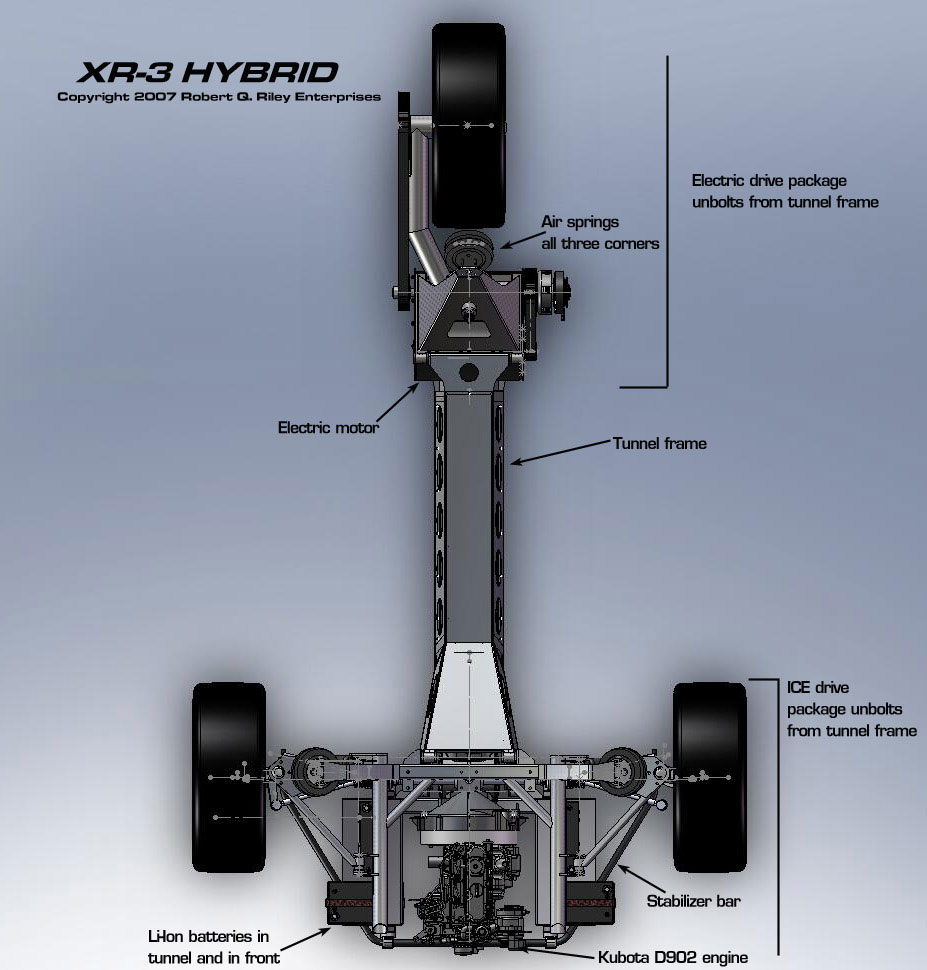

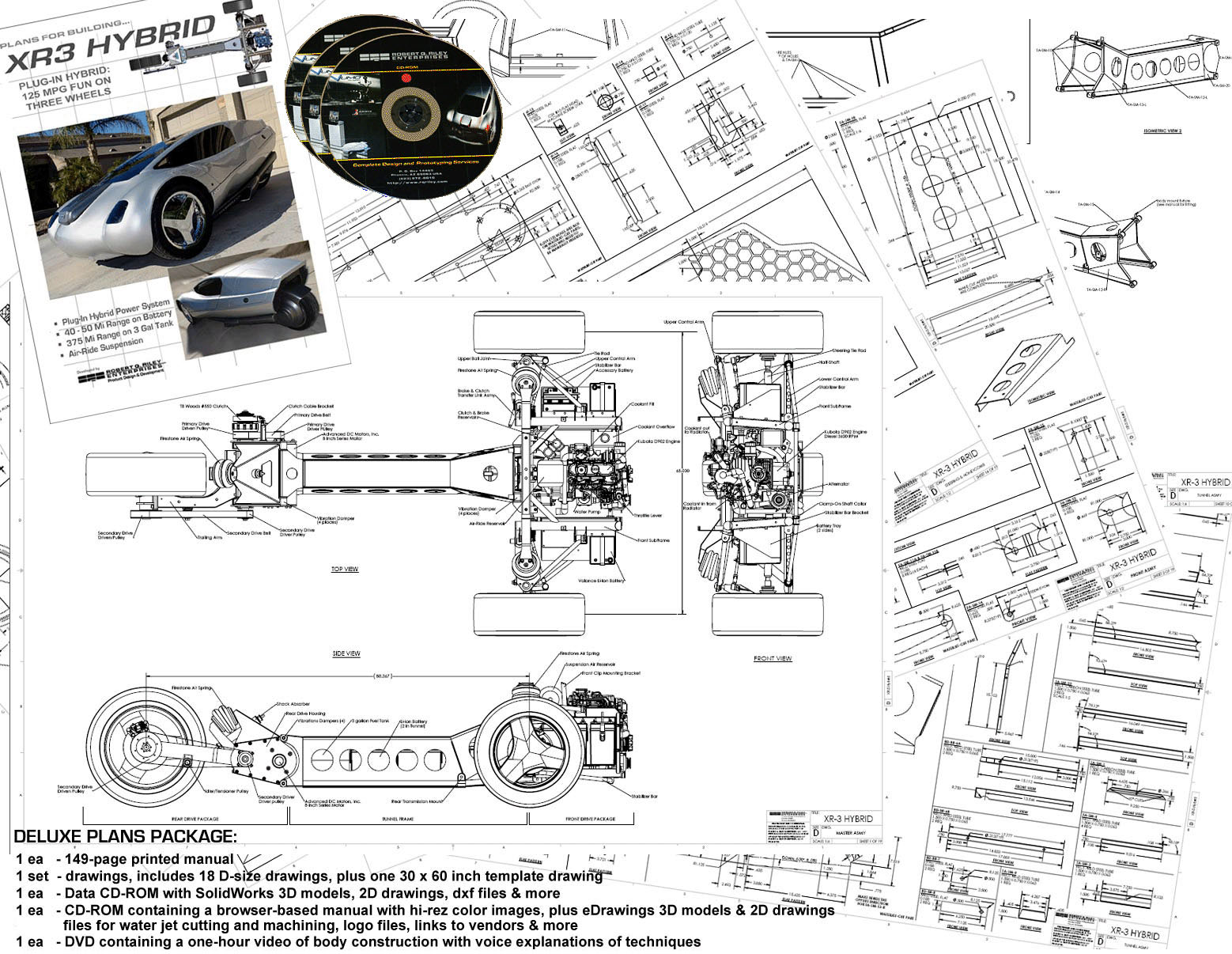

FUV is two-wheel drive with twin motors and the differential in software. It's sorted better than anything one-off. If you're interested though, something in between would be the Robt. Q. Riley X-3. https://rqriley.hostcentric.com/xr3.htm

It could be one- two- or three-wheel drive as an EV or hybrid.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

Last edited by freebeard; 11-07-2021 at 10:05 PM..

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

11-07-2021, 11:50 PM

11-07-2021, 11:50 PM

|

#153 (permalink)

|

|

Moderator

Join Date: Feb 2012

Location: Urbana, IL

Posts: 1,939

Thanks: 199

Thanked 1,807 Times in 943 Posts

|

Quote:

Originally Posted by freebeard

Theoretical friction is independent of the weight

|

Where did you get this idea? It's proportional to the load (more accurately, the normal force) acting on the tire. |

|

|

|

11-08-2021, 01:08 AM

11-08-2021, 01:08 AM

|

#154 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,340

Thanks: 8,346

Thanked 9,110 Times in 7,523 Posts

|

High school. Maybe they were wrong. Maybe it was weight transfer. All I remember is that drag racers falsified high school physics every weekend.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

11-08-2021, 11:02 AM

11-08-2021, 11:02 AM

|

#155 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,506

Thanks: 24,517

Thanked 7,436 Times in 4,817 Posts

|

high school physics

In order for them to properly address drag racing, they would have had to get into differential equations.

F = M X A just wouldn't have cut it.

Today, one can probably purchase the software.

You'd need the coefficients.

Chassis dynamometer data.

You'll never get R-R data from Goodyear race division. You'd think their Majestic-12.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

11-08-2021, 02:28 PM

11-08-2021, 02:28 PM

|

#156 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,340

Thanks: 8,346

Thanked 9,110 Times in 7,523 Posts

|

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

11-08-2021, 03:16 PM

11-08-2021, 03:16 PM

|

#157 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,506

Thanks: 24,517

Thanked 7,436 Times in 4,817 Posts

|

sliding friction

Quote:

Originally Posted by freebeard

|

I'm not a fan, and haven't looked at it since Kenny Bernstein was on top.

At that time, winning was all about the clutch.

There was no way to just hook 7,000-horsepower to the drive wheels.

They were running 32-stages of clutch engagement over the 1/4-mile, not really locking up until almost the finish line.

Burnouts heated the tires for grip.

Slippage would keep the rpms in the desired power band.

Weight transfer helped traction.

Wheelie-bars would help prevent over-rotation.

At some point they wanted the front wheels back on the track in order to steer.

As the wrinkle-walls grew in diameter from centrifugal force, the 'gearing' would be changing.

Air had to be clean enough for parachute deployment.

Really good brakes.

Delta-RR.

Delta-aero.

Really complicated orchestration of events.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following 2 Users Say Thank You to aerohead For This Useful Post:

|

|

11-22-2021, 01:59 PM

11-22-2021, 01:59 PM

|

#158 (permalink)

|

|

Master EcoModder

Join Date: Nov 2020

Location: The Pas, Manitoba

Posts: 319

Thanks: 427

Thanked 147 Times in 113 Posts

|

Well, I figure I’m just gonna use this thread as a build thread. The thread name is misleading, so maybe I’ll figure out how to change it soon.

Here’s some pics of the car as of late:

https://ecomodder.com/forum/attachme...1&d=1637606301

https://ecomodder.com/forum/attachme...1&d=1637606301

https://ecomodder.com/forum/attachme...1&d=1637606860

Some of these are sideways, sorry about that. I might switch over to my photography camera and laptop to upload better images. Proud of my work on the new front bumper, though  . It was gray originally and decimated in a crash, but I got it for $10 and used zip ties/a soldering iron to weld the whole thing back together. Painted it for ~$80, clear coated for ~$20.

One of these images shows the side view of the rear windshield. This is with the front end jacked up, which would make the rear angle even steeper. It seems quite good to me, not perfect but I’m sure there’s good enough flow over it. You can notice the radius along the width of the rear windshield. I plan to tuft test the rear and see for myself.

I’m currently learning how to do/doing the engine swap. I have another D16Y8 engine for it. I could have shot for a more efficient (HX) engine but I got this one for $400 and it’s in good enough condition, so meh. Once I get this in, I’m going to start fixing up little problems in the car, then move to testing some aero mods using cardboard/duct tape.

Edit: Anybody ever try ABS plastic sheet? Julian Edgar used it on several vehicles and it seems robust. Coroplast is cheap and super lightweight, but it didn’t hold up well on my car, and looked very rough. I want something tougher without breaking the bank.

Last edited by JacobLeSann; 11-22-2021 at 02:20 PM..

Reason: P.S.

|

|

|

|

11-22-2021, 03:21 PM

11-22-2021, 03:21 PM

|

#159 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,340

Thanks: 8,346

Thanked 9,110 Times in 7,523 Posts

|

Quote:

|

The thread name is misleading, so maybe I’ll figure out how to change it soon.

|

Petition the mods. It's the only way.

Quote:

|

I want something tougher without breaking the bank.

|

Polymetal. 1/10th the weight of plywood at twice the cost. I look for scraps at the recyclers, it's used by sign shops.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.Impossible is just something we haven't done yet. -- Langley Outdoors Academy

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

11-22-2021, 03:24 PM

11-22-2021, 03:24 PM

|

#160 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,506

Thanks: 24,517

Thanked 7,436 Times in 4,817 Posts

|

ABS sheet

Most automakers use it under their vehicles and in the wheel houses.

It's typically pre-conditioned, then vacuum-molded, while air-clamped over a hollow pattern ( which can be wood ) riddled with bleed holes, directly after leaving an electric oven.

After cooled, sent to a trim fixture where a pin-router removes any excess material or cuts open NACA inlets ( as AUDI uses ), etc..

It doesn't have much strength as a flat panel. Corrugations can be formed in for rigidity. Or strengthening structures hot-air-weld-bonded to the 'unseen' portion.

I'm unsure where an individual would purchase it. It's a commercial / industrial product, sold by the pound by a jobber. There might be a business card and minimum purchase order requirement for procurement.

We used to have a marine plastics manufacturer in the area, which gave me a complete tour of their facility and all operations, who volunteered to allow me to purchase small amounts and 'rent' their facilities for after hours production of my own, if I'd supply my own tooling.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

|