07-24-2013, 01:45 PM

07-24-2013, 01:45 PM

|

#461 (permalink)

|

|

Master EcoModder

Join Date: Dec 2008

Location: Southern WI

Posts: 829

Thanks: 101

Thanked 563 Times in 191 Posts

|

Quote:

Originally Posted by NeilBlanchard

The wood glue soaks right into the fiberglass fabric, quick as you like. I'll be testing these samples for strength.

|

Neil,

I tested foam samples with both epoxy and Elmer's Glue about two years ago. Unfortunately I can't remember if I posted the results here, but I believe so.

The Elmer's Glue samples were 25% weaker in bending than the epoxy samples.

Jim.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

07-24-2013, 01:49 PM

07-24-2013, 01:49 PM

|

#462 (permalink)

|

|

Master EcoModder

Join Date: Dec 2008

Location: Southern WI

Posts: 829

Thanks: 101

Thanked 563 Times in 191 Posts

|

Quote:

Originally Posted by Rokeby

.....I'm not convinced that your plans to use a wood glue/fiberglass laminate is a good idea....

|

I don't want Neil to learn all the bad stuff I did about using water based adhesives on a road going, water soaked vehicle.

Even snow in the winter will prove to be a formidable opponent to face! It *will* attack any weak point in the bonding of materials. Please don't make the same mistakes I did.

I *still* have issues with the water based light weight spackling, that keeps bubbling up from the heat of the sun. And this is three years after initial construction.

Don't compromise your excellent design on arbitrary cost constraints. It will start out beautiful and stay that way with the proper build techniques.

It's all posted in my tail build.

Jim.

Last edited by 3-Wheeler; 07-24-2013 at 02:00 PM..

|

|

|

|

07-24-2013, 08:20 PM

07-24-2013, 08:20 PM

|

#463 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: idaho

Posts: 282

Thanks: 0

Thanked 96 Times in 74 Posts

|

There is a way to save some money on resin when using a foam or other substrate that isn't compatible with polyester resin.

Apply a couple of coats of epoxy resin first. Spraying it on will get the smoothest coverage. You have to be 100% certain to get full, hole free coverage with the epoxy.

For big projects, use only the laminating resin until the final coat, then spray on a thin coat of finishing resin. The finishing resin contains a wax that floats to the top, sealing it from air so the surface will cure. Don't need this if you're vacuum bagging - or you can cover the resin with some type of plastic sheeting that won't bond to it.

There's a "universal" type with less wax but if you leave it too long it has to be washed with acetone to get more resin to bond to it, and the results can be iffy.

|

|

|

|

07-25-2013, 10:50 AM

07-25-2013, 10:50 AM

|

#464 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

I can buy fiberglass easily and cheaply, and glass is very strong. It is a material that will biodegrade, as well.

The vapor of epoxy is something I don't want to deal with. I cannot use polyester because of the foam I used. The Titebond III glue I am using is water*proof* even though it is water based.

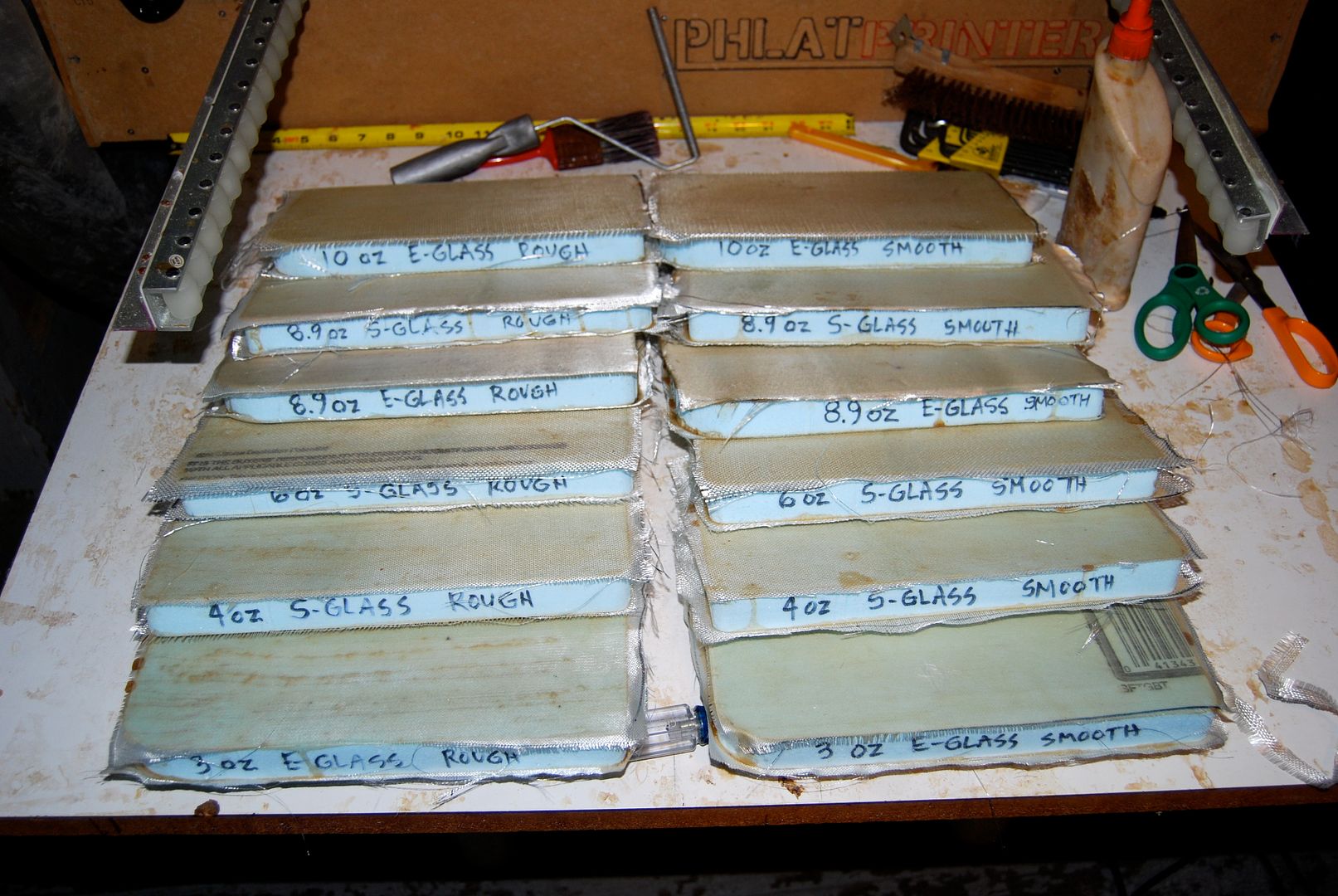

The ridged roller I used to press the fabric into the glue, and the wire brush I used to roughen the foam are in the background:

As you can see above, the printing on the foam is quite visible right through the dried fiberglass surface. Which is a neat trick, since the fabrics are not transparent, and neither is the liquid glue.

This is the 10oz E-glass smooth foam sample:

Last edited by NeilBlanchard; 07-25-2013 at 11:11 AM..

|

|

|

|

07-26-2013, 01:10 AM

07-26-2013, 01:10 AM

|

#465 (permalink)

|

|

EcoModding Lurker

Join Date: Sep 2010

Location: saint louis

Posts: 88

Thanks: 0

Thanked 4 Times in 3 Posts

|

you want the fiberglass to follow the uneven surface, the closer it follows the surface, the less excess adhesive, the stronger the structure. the proper way to address this is to smooth the foam before you glass it, as you want to lay all your glass at the same time in each section to get the best strength out of it possible.

why won't you listen to all the people telling you the ways wood glue is a bad idea? we all know from first hand experience what the right methods/materials are. your wood glue heats up when it bends? what do you think will happen around the suspension and motor mounts, anything put under constant forces? it will heat up and flex more, and more (your words), and more (the warmer it gets, the more it will flex, the more it flexes, the warmer it will get, on and on), until it gets so hot it will fail. this has fail stamped all over it, but you won't listen to the experienced professionals trying to tell you all the ways this is a bad idea. it may work fine for your tests, but in the real world, on structural areas of the car, this is a bad idea.

|

|

|

|

07-26-2013, 04:08 AM

07-26-2013, 04:08 AM

|

#466 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: idaho

Posts: 282

Thanks: 0

Thanked 96 Times in 74 Posts

|

The glue will be too flexible, especially for places where you need the structure to be very stiff. As you noted, the glue flexes and the more it flexes, the more flexible it gets until it fails.

Polyester and epoxy resins flex but not as much as wood glue AND they are much more resistant to failure from repeated small amounts of flexing. The resins made for reinforcing fiber materials have been formulated specifically for uses like your vehicle.

The only way I can see the glue working is if you build a metal frame connecting all the suspension and drivetrain mounting points so the foam coated with glue and glass won't have to support all the heavy bits that are constantly in motion at various frequencies. The body can then mainly support itself and low stress or very low vibration loads like the passengers and the batteries.

The batteries could be a problem. How does the glue, glass and foam composite stand up to a heavy load just sitting on it for a long period of time? Compound shapes will be stronger than a simple, flat "plank" shape. Of course the bottom of the battery holding areas has to be flat. A copy of a section of the battery compartment, finished how it'll be in the completed vehicle, would be a good test article to load up with batteries or weighted boxes the size of batteries.

Let sit for a period of time, in a spot where it will experience a variety of environmental conditions, especially hot temperatures. If the bottom doesn't deform then you've a design that can at least withstand long term static loading.

PVA glue loses strength at elevated temperature. I've tried to find a graph for the Titebond line but so far have only found what happens at 150F. Titebond III loses half its strength at that temperature, so I'd assume it has a pretty steep drop as temperature climbs. What happens to it at 100F? How hot will the motor get?

Another issue with PVA is bonding of it to dried PVA. Differences Between Titebond Glues | The Wood Whisperer

If you don't want to spray a coat of epoxy on the foam to protect it from the polyester resin, you can roll and brush it. A skim coat of an epoxy based body filler would give the foam a smoother surface, reducing the amount of epoxy resin required.

West System tested polyester gel coat over epoxy and found that when the epoxy was properly cured and the surface prepared, the polyester formed a very strong bond to the epoxy. WEST SYSTEM | Projects | Fiberglass Boat Repair and Restoration - Polyester over epoxy

The better you do the finish work on this body, the easier it will be to use it as a plug to make molds. Using polyester resin for the molds on a plug coated in wood glue that loses 50% strength at 150F could be a disaster since polyester resin can get pretty hot while curing. |

|

|

|

|

The Following User Says Thank You to Galane For This Useful Post:

|

|

07-26-2013, 04:15 AM

07-26-2013, 04:15 AM

|

#467 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: idaho

Posts: 282

Thanks: 0

Thanked 96 Times in 74 Posts

|

The glue will be too flexible, especially for places where you need the structure to be very stiff. As you noted, the glue flexes and the more it flexes, the more flexible it gets until it fails.

Polyester and epoxy resins flex but not as much as wood glue AND they are much more resistant to failure from repeated small amounts of flexing. The resins made for reinforcing fiber materials have been formulated specifically for uses like your vehicle.

The only way I can see the glue working is if you build a metal frame connecting all the suspension and drivetrain mounting points so the foam coated with glue and glass won't have to support all the heavy bits that are constantly in motion at various frequencies. The body can then mainly support itself and low stress or very low vibration loads like the passengers and the batteries.

The batteries could be a problem. How does the glue, glass and foam composite stand up to a heavy load just sitting on it for a long period of time? Compound shapes will be stronger than a simple, flat "plank" shape. Of course the bottom of the battery holding areas has to be flat. A copy of a section of the battery compartment, finished how it'll be in the completed vehicle, would be a good test article to load up with batteries or weighted boxes the size of batteries.

Let sit for a period of time, in a spot where it will experience a variety of environmental conditions, especially hot temperatures. If the bottom doesn't deform then you've a design that can at least withstand long term static loading.

PVA glue loses strength at elevated temperature. I've tried to find a graph for the Titebond line but so far have only found what happens at 150F. Titebond III loses half its strength at that temperature, so I'd assume it has a pretty steep drop as temperature climbs. What happens to it at 100F? How hot will the motor get?

Another issue with PVA is bonding of it to dried PVA. Differences Between Titebond Glues | The Wood Whisperer

If you don't want to spray a coat of epoxy on the foam to protect it from the polyester resin, you can roll and brush it. A skim coat of an epoxy based body filler would give the foam a smoother surface, reducing the amount of epoxy resin required.

West System tested polyester gel coat over epoxy and found that when the epoxy was properly cured and the surface prepared, the polyester formed a very strong bond to the epoxy. WEST SYSTEM | Projects | Fiberglass Boat Repair and Restoration - Polyester over epoxy

The better you do the finish work on this body, the easier it will be to use it as a plug to make molds. Using polyester resin for the molds on a plug coated in wood glue that loses 50% strength at 150F could be a disaster since polyester resin can get pretty hot while curing. |

|

|

|

07-26-2013, 05:55 AM

07-26-2013, 05:55 AM

|

#468 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,032

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Choosing unsuitable materials to build a car's structural element is like a suicidal attempt.

|

|

|

|

07-26-2013, 07:48 AM

07-26-2013, 07:48 AM

|

#469 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2012

Location: 21244

Posts: 8

Thanks: 0

Thanked 0 Times in 0 Posts

|

I'm no structural engineer by any means, but I've been checking out this thread every day for a year now, and I ahve to admit that I'm in mini panic mode after everyone's comments about the glue you plan on using. I really think you're idea to create a kickstarter campaign is a good one. you could easily raise enough money to use the proper materials and bring this amazing project to life without carrying the entire financial burden yourself. i'm sure there are plenty of people on here that could help you make a video about the Carben to help sell the kickstarter. I know I'd be willing to help in any way that I could

I just don't want to see the carben fail at this point after watching your vision come to life over the past year!

|

|

|

|

07-26-2013, 08:29 AM

07-26-2013, 08:29 AM

|

#470 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,032

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Quote:

Originally Posted by bbennett2

I just don't want to see the carben fail at this point after watching your vision come to life over the past year!

|

I'll have to second that. It would be such a pity if you wasted an outstanding project because of an unsuitable material.

|

|

|

|

|