This might be a little premature to post, but as I thought someone may have an idea or spot a problem I might be overlooking, maybe now is the time before everything gets locked in place. I created a thread a few days ago with the idea, but there seemed to be no interest. I feel the system really has a chance at succeeding, but we'll see where it goes whether it's failure or success.

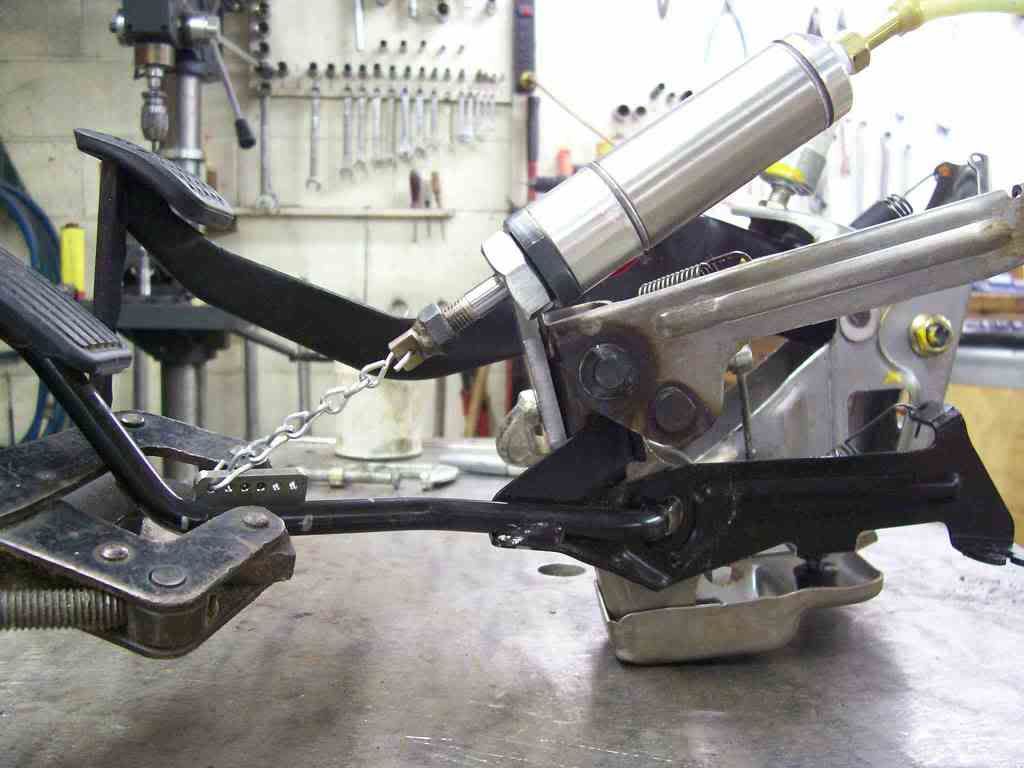

The basic objective is that the driver feels an increasing resistance in the throttle pedal with increasing manifold pressure, therefore without monitoring a manifold pressure gauge one should be able to "feel" the load of the engine in the pedal feedback. In theory, you should be able to take a constant rate spring and apply a constant pressure to the gas pedal and the pedal should ride where it wants to retaining a constant manifold pressure throughout the entire rpm range. This will aid in preventing inefficient manifold pressure conditions and increase economy significantly in the city for the untrained ecohead.

Not only could this benefit the economy crowd, but for the "go fast" nut as well in the name of traction control especially in non-linear torque curves as in boosted engines.

There were several constraints that had to be worked around as well as guesswork. At present, the pedal should increase pressure by 5 lbs of force at ambient MAP. I have no idea what that will be in reality during regular driving whether it fatigues the foot or isn't noticeable at all. I can make another hinge pin and step up a cylinder size if necessary, but hopefully it doesn't come to that.

I'll post progress or antiprogress as the system matures.