11-25-2007, 09:11 PM

11-25-2007, 09:11 PM

|

#131 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

07-18-2006, 08:00 Pm

DAX suggests:

Quote:

|

Whatever kind of coupler you come up with, I would consider getting it case hardened

|

Thanks - that's a new term to me. (case hardened)

In order of most to least common, I'd say people use taper locks (on the external keyed motor shaft) connected to a flange that the clutch plate is then bolted to (or they retain the flywheel and normal clutch action).

After that, people use "Lovejoy" connectors.

After that, they make up whatever seems to works. (That'll be us.)

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-25-2007, 09:11 PM

11-25-2007, 09:11 PM

|

#132 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

07-19-2006, 10:23 Pm

Ivan located a scrap piece of 3/4 in aluminum the right size for the adapter plate. Price: free!

---

And as if I don't have enough projects, I've been itching to make a trailer for my beater 10-speed (which I spend more time on than in my car in the summer). Half the time I fire up the car these days, it's to bring something down to the boat that's too big to carry in my knapsack on the beater bike. Which tells me: time to get a bike trailer.

I have all the junk needed to make something like this ... including the electric motor... so it could also be a "pusher trailer".

Details: http://www.electric-bikes.com/bidwell.htm |

|

|

|

11-25-2007, 09:12 PM

11-25-2007, 09:12 PM

|

#133 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

07-21-2006, 04:32 Pm

Adapter plate cut!

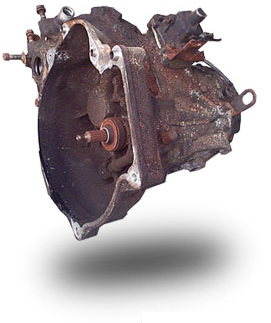

It's ready to become the meat in the sandwich between this...

... and this ...

Next step is to drill the bolt holes in the plate, then figure out how the heck we're going to join the shafts of the tranny & motor...

---

(Also bought some electrical conduit to make a bike trailer frame this weekend... probably won't electrify it right away, but that's the goal...)

|

|

|

|

11-25-2007, 09:13 PM

11-25-2007, 09:13 PM

|

#134 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

07-22-2006, 08:55 Pm

Made the frame for my bike trailer today. The plan is it will eventually become an electric pusher trailer.

It's bigger than the one in the pic above - partly because the motor I have is about 5x the size of the one shown, and partly because I want to be able to carry more stuff than you can fit in the little bin on that one.

But it's smaller than those kid-towing trailers you often see around. When it's totally finished, the frame will fit something about the size of a full size cooler ... and an electric motor.

Just have to figure out how the hitch will work. And what kind of material to use for the "bed". I don't want to use diamond plate due to the added weight and expense. This is another ForkenSwift approach: cheap, cheap, and, oh yes, cheap.

My expenses so far: $7.50 for a rusty kids bike - for the wheels & dropouts; $10 for 20 feet of electrical conduit for the frame; not counted: oxy-acetylene & 2 brazing rods; misc bits & pieces out of Ivan's parts bin).

Anyone have any ideas what I could use for the bed that's cheap (or free) & light? Some kind of thick plastic? Something fiberglass? Some kind of sturdy metal grid/mesh? Hmmm...

|

|

|

|

11-25-2007, 09:14 PM

11-25-2007, 09:14 PM

|

#135 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

SVOboy replies...

Quote:

|

You could cut an old cooling tray (like for baking) down to size, prolly pick one up from a junk sale or thrift store for cheap.

|

That's a good idea - and it made me think of another one: a grill from an oven (the racks inside, you know?). |

|

|

|

11-25-2007, 09:21 PM

11-25-2007, 09:21 PM

|

#136 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

07-24-2006, 08:10 Pm

I may have a lead (pardon the pun) on a cheap ForkenSwift battery pack.

A friend of my neighbour works as a contractor for the local cable company. He said they recently ordered new 12v batteries for all their remote power supplies (grey boxes on phone poles), and then decided to change to a different power supply... which uses a different battery.

So, if you can believe it, they have already taken over 100 of these brand new, unused batteries to the recyclers. $160 new ... couple of bucks as scrap.

They are almost certainly the wrong type of battery for an electric vehicle, but for a first pack, they'll be great, even if they don't last very long. He says they're a gel electrolyte, and about the same size as a standard car battery.

I told him I'd like at least 8 (for a 48V pack), and possibly more... for the car, boat & other stuff.

Fingers crossed...

|

|

|

|

11-25-2007, 09:22 PM

11-25-2007, 09:22 PM

|

#137 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

08-14-2006, 12:14 Pm

First, as promised, the bike trailer I made. Attached to the back of my beater bike, which I normally put more kilometers on than my car in an average non-winter week.

Trailer not yet electrified (and minus a bed)...

Click to zoom. Tricycle for scale. |

|

|

|

11-25-2007, 09:26 PM

11-25-2007, 09:26 PM

|

#138 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

08-14-2006, 12:21 Pm

Second: back to the ForkenSwift.

After a too-long delay, Ivan and I spent an hour on it this morning. Hopefully the inertia will carry it along a little more regularly now that we've started on it again...

The adapter plate is now drilled and attached to the transaxle (the Blackfly's old transaxle - which is, of course, identical to the one in the blue ForkenSwift which will ultimately be used).

So we're officially at the most critical engineering stage: choosing a motor/transmission input shaft coupler design, and implementing it.

The parts we have to work with are the splined male hydraulic pump shaft (fits into the motor shaft), and the splined "hub" of the clutch plate that fits on the tranny input shaft.

One option that I know has been used is adapting a Lovejoy connector to mate those 2 (dissimilar) parts:

http://www.lovejoy-inc.com/jawtypecouplings.htm |

|

|

|

11-25-2007, 09:27 PM

11-25-2007, 09:27 PM

|

#139 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

08-14-2006, 01:37 Pm

Quote:

|

Originally Posted by SVOboy

How much did it cost for the tranny adapter plate?

|

It was gratis for the metal. Scrap. Ivan cut it & we drilled it. |

|

|

|

11-25-2007, 09:28 PM

11-25-2007, 09:28 PM

|

#140 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

Quote:

|

Originally Posted by SVOboy

*getsangry*

Dude, that's awesome. that crap cost like 900 dollars for hondas. Make me one so I can use my tranny with the new L12!

|

Make yer own! The material wouldn't have cost much - $60-70 CDN pesos, had we had to cough up the cash. Aluminum (the stuff we got, anyway) is very easy to work (soft).

We could have bought one from an EV supplier for roughly $150 US.

Quote:

|

Yeah, I guessssss. Not gonna fool with serious fab work until I go EV.

|

|

|

|

|

|