08-28-2014, 05:55 PM

08-28-2014, 05:55 PM

|

#1031 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,154

Thanks: 8,277

Thanked 9,039 Times in 7,470 Posts

|

Quote:

|

I need to learn how to post pics around here. I could post some scribbles that would help illustrate these babbles...

|

Please do. Just look for an icon of a landscape with a yellow sky at the top of the message box. The real trick is having the picture to post. If you sketch on paper and have a smart phone/digital camera, lay it on a kitchen counter (kitchens have good lighting) and hold the phone/camera against the bottom of a cabinet to simulate a tripod.

How about a fourth possibility: Install in a lightweight, aerodynamic body where it will be understressed and hook up the heat sensor to see if additional cooling is needed.

After the gearset is subjected to Isotropic Superfinishing?

|

|

|

|

|

The Following 2 Users Say Thank You to freebeard For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

08-28-2014, 07:03 PM

08-28-2014, 07:03 PM

|

#1032 (permalink)

|

|

Permanent Apprentice

Join Date: Jul 2010

Location: norcal oosae

Posts: 523

Thanks: 351

Thanked 318 Times in 215 Posts

|

This might seem silly, but... my wife came home and complained about various coworkers (politics) and I really got thinking how fortunate I am and what a great group of "coworkers" you folks are.

Here's a pic test; it's a relatively small (memory) size picture:

d'oh! I need to post it someplace online first.....  I'll get it just hang on . .

Oh, by the way, monitoring if the electric pump is working isn't a bad option. I mean it would be possible to monitor both oil pressure and temperature as well as the motor's stator temperature. However, if the oil pressure drops and the temperature starts to increase I would think it would require an *** immediate *** stop & fix.

Last edited by e*clipse; 08-29-2014 at 03:38 AM..

Reason: try adding pic, then remove extra "IMG" tags, then change "guy" 'cause there are more contributers, and everyone's welcome!

|

|

|

|

|

The Following 3 Users Say Thank You to e*clipse For This Useful Post:

|

|

08-28-2014, 08:03 PM

08-28-2014, 08:03 PM

|

#1033 (permalink)

|

|

Master EcoModder

Join Date: Sep 2010

Location: Saskatoon, canada

Posts: 1,488

Thanks: 746

Thanked 565 Times in 447 Posts

|

Quote:

Originally Posted by e*clipse

Oh, by the way, monitoring if the electric pump is working isn't a bad option. I mean it would be possible to monitor both oil pressure and temperature as well as the motor's stator temperature. However, if the oil pressure drops and the temperature starts to increase I would think it would require an *** immediate *** stop & fix.

|

You can monitor a bunch of stuff. This list is my personal, off-the-top-of-my-head, cheap and easy order:

1 - the current used by the motor when *ACTUALLY* pumping. This is an interlock to the controller that will not allow the car to move if the pump is not working.

2 - a sensor (analog or just a switch) in the line that shows oil flow but wastes some of the pump capacity, again as an interlock to the controller

3 - measure the temperature of the part that needs cooling/lubrication and have both an alarm value and a shutdown value that again, shuts down the controller

1 - a Hall effect sensor can give a signal to a simple comparator that feeds Good/Bad to the controller; maybe $20 for OK parts.

1 - or if there is an overall car controller you can go analog and use a setpoint, and deadband, and all that good stuff. Less money if there is already a car controller and a display - maybe $10?

2 - flow switch already is Good/Bad signal, ready for the controller. Flow switches are not that reliable, but the small size means you can use hydraulic sensors. Maybe $50 or so

3 - temperature sensor would have to be non-contact. An IR sensor pointing at the part, that can be soaked in oil ... perhaps a bit of a challenge. But it is the best protection since you are detecting (likley) the highest part that needs oil, and also determining if the oil cooling is being effective. If the motor temperature is a good indication of oil circulating - that's easy to do.

I don't like flow sensing. It's great when it works, but it's a bit of a pain to calibrate. Pressure is easier to calibrate but does not show flow by itself. Temperature is awesome with RTDs and Thermocouples - no calibration! Current sensing is not very accurate, on average, but can be checked with a clamp-on meter and is close enough to give you information ... like if the pump is MOVING oil.

Just my 2 cents. |

|

|

|

|

The Following 2 Users Say Thank You to thingstodo For This Useful Post:

|

|

08-28-2014, 08:12 PM

08-28-2014, 08:12 PM

|

#1034 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

e*clipse! I was thinking the exact same thing! We are seriously one heck of a team of fellow collaborators! And We never have any TPS reports to fill out (office space).

I post photos to photobucket using my cell phone, then click on the "share links" IMG, and then paste it here:

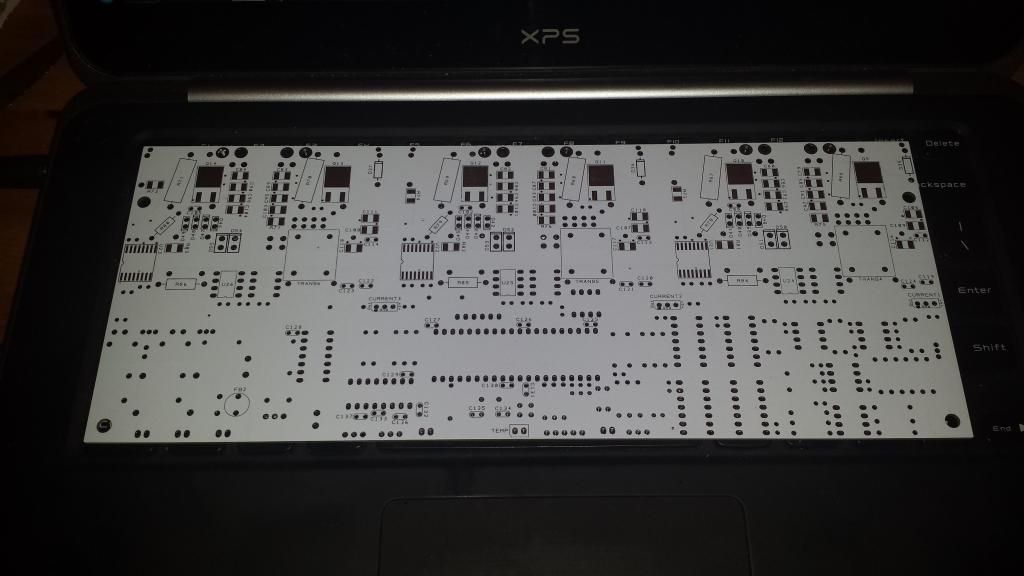

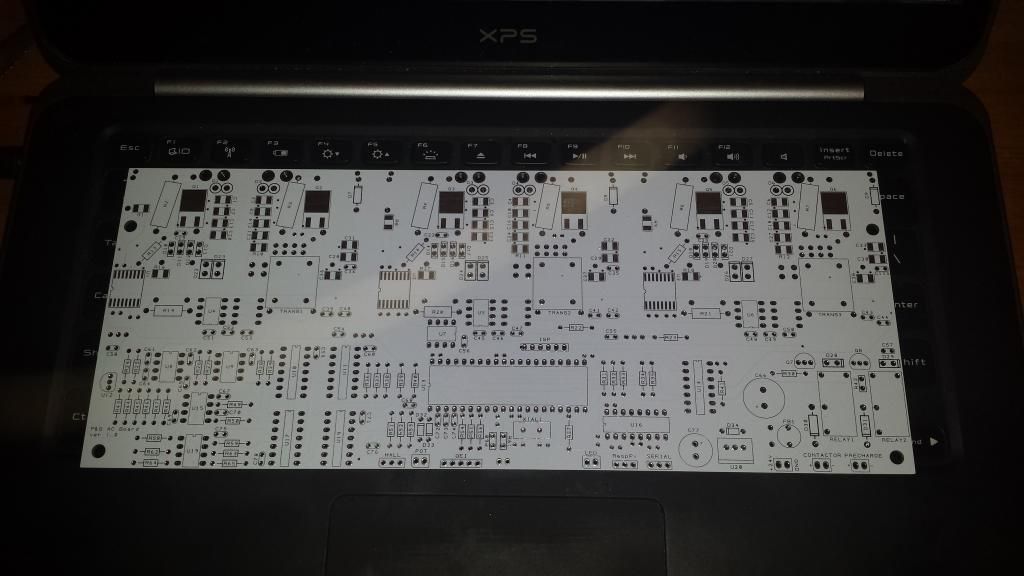

The control/driver boards arrived a couple days early! This is the back:

And this is the front:

Now I just need to order the control board parts. I had made a saved cart, or so I thought, but it has ceased to exist. Very mysterious.

I also got an encoder attached to the bigger AC motor that turned up. I discovered that VHB tape isn't very sticky in 120degF weather. The stupid encoder was glued to the flat aluminum plate thing that I attached to the motor, centered perfectly with a centering tool, and then when I touched it, it moved, totally losing center. It was fully assembled and not unassemblable. So, I gave it a push and eyeballed it, and gosh darn it, if that thing isn't centered, then I'm a monkey's uncle. Then I glued around the edges of the encoder to the back plate using some epoxy. It's stuck now. It should work OK.

Last edited by MPaulHolmes; 08-28-2014 at 08:17 PM..

|

|

|

|

|

The Following 3 Users Say Thank You to MPaulHolmes For This Useful Post:

|

|

08-29-2014, 12:12 AM

08-29-2014, 12:12 AM

|

#1035 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,154

Thanks: 8,277

Thanked 9,039 Times in 7,470 Posts

|

e*clipse -- We haven't talked about politics, that's for The Lounge. I'm a social anarchist.

Good job. The extra IMG tags tells me the post looked like:

Code:

[IMG][IMG]mypic.jpeg[/IMG][/IMG]

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

08-29-2014, 03:01 AM

08-29-2014, 03:01 AM

|

#1036 (permalink)

|

|

Permanent Apprentice

Join Date: Jul 2010

Location: norcal oosae

Posts: 523

Thanks: 351

Thanked 318 Times in 215 Posts

|

Um, It seems I could ramp up some stuff about the Toyota MGR that might be useful for folks around here, but honestly is not related to AC controller stuff. I really don't want to pollute Paul's thread, and their might be enough stuff to warrent a thread of it's own.

What do you guys think?

|

|

|

|

|

The Following 2 Users Say Thank You to e*clipse For This Useful Post:

|

|

08-29-2014, 03:33 AM

08-29-2014, 03:33 AM

|

#1037 (permalink)

|

|

Permanent Apprentice

Join Date: Jul 2010

Location: norcal oosae

Posts: 523

Thanks: 351

Thanked 318 Times in 215 Posts

|

Thanks for the helpful list, Thingstodo!

I was thinking that a 3 phase motor might be more reliable than a brushed dc motor (to power the pump) Would you find this true? Perhaps a really simple sensorless-type controller could be used? I suppose if a 3-phase motor is used, the controller could give an "everythings working" ok signal. Also, could a **very rough** hall-effect type sensor be used for a minimal 3-phase control? I mean, theoretically, no control at all is needed, just a rotating magnetic field. If the hall effect sensor detected that the rotor wasn't turning even though the magnetic field was, then perhaps the pump is jammed?

Next to knowing if the pump is turning, a pressure gauge/switch would be pretty simple. I agree that knowing there is pressure does not mean there's flow. Example: high pressure in front of a clogged filter.

I also agree that monitoring temperature (accurately) can be pretty easy. I just got a PID controller for my espresso machine, and setting up the temperature sensor was extremely easy.

So a combination of pressure gauge an temperature sensor would be quite effective in verifying that an oil system is working. Minimum pressure at a specific point along with a maximum temperature at another point in the system would verify operation.

So, perhaps with the right monitoring and a reliable power source, and external pump would not hurt the system reliability.

- E*clipse

Quote:

Originally Posted by thingstodo

You can monitor a bunch of stuff. This list is my personal, off-the-top-of-my-head, cheap and easy order:

1 - the current used by the motor when *ACTUALLY* pumping. This is an interlock to the controller that will not allow the car to move if the pump is not working.

2 - a sensor (analog or just a switch) in the line that shows oil flow but wastes some of the pump capacity, again as an interlock to the controller

3 - measure the temperature of the part that needs cooling/lubrication and have both an alarm value and a shutdown value that again, shuts down the controller

1 - a Hall effect sensor can give a signal to a simple comparator that feeds Good/Bad to the controller; maybe $20 for OK parts.

1 - or if there is an overall car controller you can go analog and use a setpoint, and deadband, and all that good stuff. Less money if there is already a car controller and a display - maybe $10?

2 - flow switch already is Good/Bad signal, ready for the controller. Flow switches are not that reliable, but the small size means you can use hydraulic sensors. Maybe $50 or so

3 - temperature sensor would have to be non-contact. An IR sensor pointing at the part, that can be soaked in oil ... perhaps a bit of a challenge. But it is the best protection since you are detecting (likley) the highest part that needs oil, and also determining if the oil cooling is being effective. If the motor temperature is a good indication of oil circulating - that's easy to do.

I don't like flow sensing. It's great when it works, but it's a bit of a pain to calibrate. Pressure is easier to calibrate but does not show flow by itself. Temperature is awesome with RTDs and Thermocouples - no calibration! Current sensing is not very accurate, on average, but can be checked with a clamp-on meter and is close enough to give you information ... like if the pump is MOVING oil.

Just my 2 cents.

|

|

|

|

|

08-29-2014, 06:07 AM

08-29-2014, 06:07 AM

|

#1038 (permalink)

|

|

Dreamer

Join Date: Nov 2013

Location: Australia

Posts: 350

Thanks: 95

Thanked 214 Times in 151 Posts

|

With the oil system i would say that oil flow, oil pressure, pump turning, pump current etc. really wouldn't be necessary. They all add up to the same thing, an Indication that the drive motor needs to be stopped.

A simple temperature monitor on the motor would give an indication of all those other failure modes. The motor temperature goes up higher than expected from current load, passes a set threshold and then warns the driver.

Maybe a gradual power reduction as the temperature got more and more away from expected values. As auto shut down of the motor could be dangerous depending on the current driving situation.

The temperature sensor would also tell you if you are able to drive at a greatly reduced load in order to get yourself home. Sort of like an ICE engines limp home mode (grumble mode).

These extra sensors would be helpful in fixing the problem but once you are able to start looking at repairing the problem you presumably would have the time to measure many of these things directly or at least diagnose them.

|

|

|

|

|

The Following 2 Users Say Thank You to Astro For This Useful Post:

|

|

08-29-2014, 05:12 PM

08-29-2014, 05:12 PM

|

#1039 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,154

Thanks: 8,277

Thanked 9,039 Times in 7,470 Posts

|

I'm off to muck around downtown right now, but before Monday I will have started a thread in this subforum titled, probably, Pre-Build Thread Questions. It will lead off with questions I have about recharging infrastructure, in-car systems security, battery/supercap options, packaging of the Open Revolt controller/power boards and such like. And rants about the awesome hidden power of Open Sourcing the software development.

I'd like to see a thread called How To Hot-Rod the Lexus 3rd Member. How long does it take to tear down and reassemble. Step-by-step pics. What it looks like installed in the donor vehicle.

For now though—I'd want to rely on the stock temp output, and then characterize the performance after the following on the gearset parts:

Magnaflux to insure reliability

Cryogenic tempering to deter wear

Isotropic Superfinishing to control temperature and increase gearset efficiency |

|

|

|

|

The Following 2 Users Say Thank You to freebeard For This Useful Post:

|

|

08-29-2014, 06:32 PM

08-29-2014, 06:32 PM

|

#1040 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Mouser parts ordered. Priority shipping. About $138 per board in quantity 2.

|

|

|

|

|

The Following User Says Thank You to MPaulHolmes For This Useful Post:

|

|

|