12-27-2010, 05:43 PM

12-27-2010, 05:43 PM

|

#461 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

I attached the bus bars, and soldered all of the mosfets and added all the gate resistors and what else... It's funny all the little details that I'm finding by actually putting it together that I never noticed before.

I also drilled the mounting board for the control board. Now I just need to wait for those 2" female on each end metal spacers to arrive. The power board is underneath. Then 2 inches up, there's the mounting board, and then about 1/4" above that there's the control board. Another irritating thing is the stupid piece of metal I'm using for the baseplate isn't wide enough for mounting the current sensors. I'm not sure what I'll do about that. It's just a prototype though. I guess sitting in the garage is good eough for testing.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

12-27-2010, 08:03 PM

12-27-2010, 08:03 PM

|

#462 (permalink)

|

|

EV guy

Join Date: Sep 2008

Location: Ann Arbor MI

Posts: 4

Thanks: 0

Thanked 0 Times in 0 Posts

|

Great work Paul!

I finally had a chance to read the whole thread and study the schematics, holidays are good for something!

A few questions:

- What LEM part are you using?

- Are there schematics and BOM for the mosfet power boards somewhere?

Thanks!

|

|

|

|

12-27-2010, 10:34 PM

12-27-2010, 10:34 PM

|

#463 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

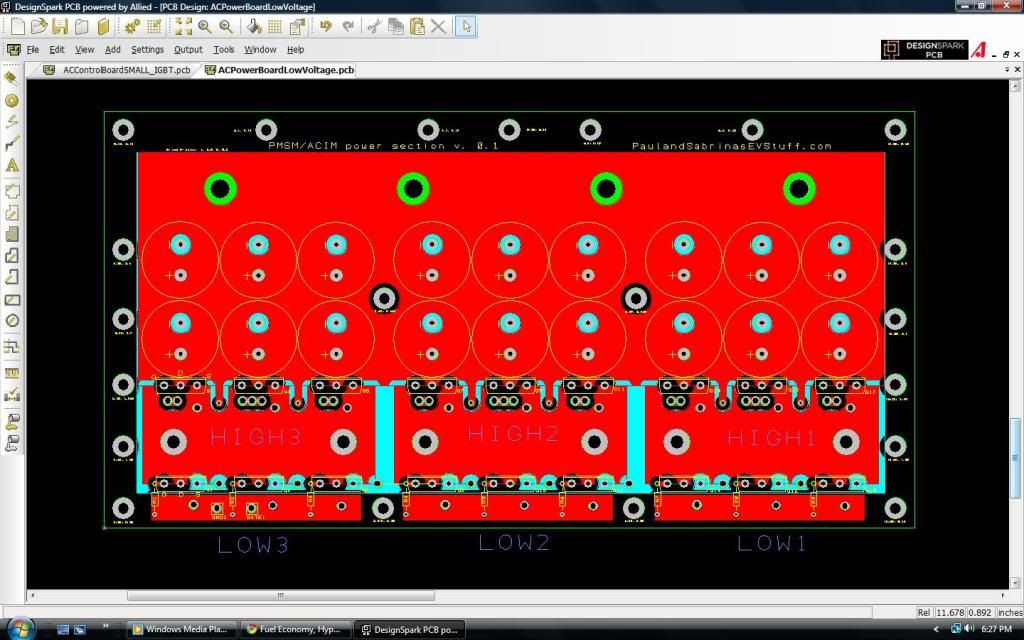

Hi Erik! I just made the power board layout without a schematic. I know that's not good practice though. Here's a picture of it:

Let's take phase 3 for example. B+ is the top plane of the board. B- is the bottom plane of the board. B+ and B- bars are on top and bottom of board respectively. Right at the top. B+ and B- share the same 4 holes. B- goes out the upper left side, and B+ goes out the upper right side. So, first you hit the bus capacitors. Then you hit the 3 high side mosfets. Then the 3 low side mosfets. The extra holes under the 3 high side mosfets are just there to add the gate resistors. They should really be on a separate board, and I"m going to make that change next time. The mosfets lay flat underneath the power board, against a base plate. I need to get some pictures of the assembly.

By the way, you are welcome to the files. I used DesignSpark, which is free, and can generate Gerber files. Oh ya, and I'm just using some LEM Hass 50-s sensors for low power tests (less than 50 amps per phase) and the higher power tests I'll use LEM Hass 300-s, which will have a limit of 300 amps per phase.

Last edited by MPaulHolmes; 12-28-2010 at 12:00 AM..

|

|

|

|

12-28-2010, 03:32 PM

12-28-2010, 03:32 PM

|

#464 (permalink)

|

|

EV guy

Join Date: Sep 2008

Location: Ann Arbor MI

Posts: 4

Thanks: 0

Thanked 0 Times in 0 Posts

|

Thanks Paul!

So I see 18 of IXFK230N20T. What max phase current do you think this setup will handle? How far do you de-rate the voltage and current limits? And what part number for the bus caps? Is the driver circuit for the mosfet setup the same as on the schematics for the IGBT version?

Perhaps I should explain my interest, at the risk of being long-winded. I'm chief engineer at a company making electric motorscooters and motorcycles. We're using BLDC hub motors, 5kw continuous, 12kw or more intermittent. Right now we're purchasing controllers, but we're not very happy with them. So I'm searching for alternatives and thinking about make versus buy decisions. Now, we have a theoretical 400 amp phase current rating, but only for 20 seconds. Less than 200 amps continuous. 120v nominal, 144v max. Mosfets not IGBTs.

So my first objective is to get a handle on a BOM cost for your controller, sized for our application, that I can show to the "suits" to show that the idea has potential. My second objective is to "follow along" and learn from your project. I already know lots of things that can go wrong with big inverters! :-) And the possible longer-range goal might be to build something similar. I expect that along the way I would contribute both financially and technically to the project.

So that's where I'm coming from. Is there anything I can do to help, while I'm catching up on this whole project?

- Erik K

|

|

|

|

12-28-2010, 05:20 PM

12-28-2010, 05:20 PM

|

#465 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Hi Erik! According to the datasheet for the mosfets, the legs are good for 160amp, and the actual mosfet is good to 230amp (ya right). So, I was thinking that with good heatsinking, they might take 100 amps each for some amount of time that is to be determined. I'm using the TO-264 package, but the TO-247 plus package has the same ratings. The big black bus capacitors are these:

EET-ED2D102CA Panasonic Electronic Components Aluminum Electrolytic Capacitors - Snap In.

It's the same ones that I have been using in the DC motor controller. I'm also using some metal polypropylene caps right at the mosfet legs (from B+ on the high side to B- on the low side):

Digi-Key - 495-2918-ND (Manufacturer - B32674D4225K)

There are a few quirks during assembly that I have encountered so that the power board should be tweaked a bit.

I think 144v is safe with these 200v components because people have been using 200v components at 144v nominal on the DC controller (so really like 150's), and it seems to be working well.

I've added voltage monitoring to the DC board, and will add to the AC board too. That will make regen safer. You can have the AC control board files. It's through-hole, so the dang thing is big. I need to convert it to surface mount. Change whatever you want. It's a little overkill right now. There are 6 isolated DC-DCs, but you really could get away with only four I think. 3 high side, and 1 for the 3 low side ones.

Last edited by MPaulHolmes; 12-28-2010 at 05:31 PM..

|

|

|

|

12-28-2010, 06:48 PM

12-28-2010, 06:48 PM

|

#466 (permalink)

|

|

EV guy

Join Date: Sep 2008

Location: Ann Arbor MI

Posts: 4

Thanks: 0

Thanked 0 Times in 0 Posts

|

Thanks Paul!

That all makes sense.

I don't need board files yet, need to understand the design better (and sell it to the suits, er, fit it in the budget) before building anything.

How many microseconds does it take the over-current limit to activate?

I haven't studied the software, is there code to predict current limits and adjust on time to avoid over-current? Some way to adjust it or have it learn about different motors?

I guess I should dive into the code, BLDC motors are a bit different to drive than ACIM. Simpler in some ways, but still different. The code posted on the wiki is reasonably up to date?

How easy have you found the Microchip code to work with? I've done a lot of PIC work but never DSPic. Have you had to write a lot, or is it still mostly the Microchip example code?

Thanks again!

|

|

|

|

12-28-2010, 07:15 PM

12-28-2010, 07:15 PM

|

#467 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Oh man, testing is getting close now!

In practice with the DC controller, the hardware overcurrent protection never comes on, because the PI loop has been tuned nicely, so that the current chases the throttle position. And max throttle is set to 500 amps (well 505) in software with zero current overshoot. If there were overshoot, the LEM response time would be between 1 us and less than 5us, depending on the severity of the current jump. There's also a low pass filter before the hardware overcurrent, which has an RC time constant of something like 1/50000 sec I think. I'll have to check that because I forgot what R and C I used. The nice thing is, you could eliminate that, or make it as fast as you want. The rest of the hardware overcurrent circuit is very quick. Just a couple nand gates, which have response times of a few nanoseconds.

In the case of the AC or PMSM, it's looking at each of the 3 phases, and if any one of them goes out of bounds, all the pwm channels are disabled until the naughtiness has ceased. I believe the response time will be similar. Also, I think that hardware overcurrent won't be very necessary once the field oriented control gets working nicely, because then it's basically just like a DC controller. I_field chases zero (hurray for permanent magnets), and I_torque chases throttle position, just like the DC good old days. Well, there's field weakening that you can add, where you set I_field negative to fight against the magnets to spin it faster.

So, Less than 5 uS if there's no low pass filter before the hardware overcurrent part.

I forgot that there was even wiki code. I have no idea how recent it is. I have some code on my computer that runs the AC controller with the V/Hz = constant (actually, V = constant because I had such low voltage testing). I'll upload it again once I do a little testing.

I've never done any PIC programming. Only atmega8 and atmega168, and then dsPIC30F. It was truly annoying to get everything initialized with the dsPIC, but once all the bits are set, it's just C and everything is the same, so it's not bad. And the dsPIC is pure motor control. Everything you want a microcontroller to do for running a motor, it does naturally.

Last edited by MPaulHolmes; 12-30-2010 at 03:02 PM..

|

|

|

|

12-28-2010, 08:44 PM

12-28-2010, 08:44 PM

|

#468 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

OK, I need male spade connectors. Dang it! I was just at HOme Depot! Stupid idiot! Bye! I just ahve to connect the dang blasted throttle. Makes me mad.

|

|

|

|

12-29-2010, 03:55 PM

12-29-2010, 03:55 PM

|

#469 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Oh yes, the software on the wiki is definitely out of date. It's almost completely different from the Microchip code. Only one part is the same, and that's where you are doing the space vector pwm part, where you figure out how much pwm to set for each channel, based on where all the vectors are. My version is all C, and microchip's is assembly. Microchip also used floating point I believe, whereas I used fixed point integer multiplying. The goal was to have code be easier to follow, and not to learn pic assembly. haha. I've only done assembly language on regular computers.

It's all wired up now! Well, there's no fuse, but there's a contactor that can break 2000 amps. I have a slow blow fuse in the car that's rated for 300 amps, but the wiring I'm using is only good for 50 amps barely, so I didn't see a point in a fuse, but maybe I should.

Now the debugging of a ton of totally untested field oriented control code on a PMSM motor! I've never used the encoder before, so I hope it works like it should. Man, I think this part is going to be a challenge. Nothing like a DC controller. But I have the serial port all ready to go, and I'm going to need to see all that stuff going on. ya!

|

|

|

|

12-29-2010, 05:57 PM

12-29-2010, 05:57 PM

|

#470 (permalink)

|

|

Master EcoModder

Join Date: Sep 2009

Location: Ireland

Posts: 734

Thanks: 26

Thanked 304 Times in 171 Posts

|

Paul you need a fuse. Cos if you die who's gonna supply me with pcbs ?

__________________

Now, Cole, when you shift the gear and that little needle on the ammeter goes into the red and reads 2000 Amps, that's bad.

www.evbmw.com

|

|

|

|

|