Paul,

Ever since i saw the copper sheet connecting the IGBT's to the Ring cap i have thought why not use something more solid.

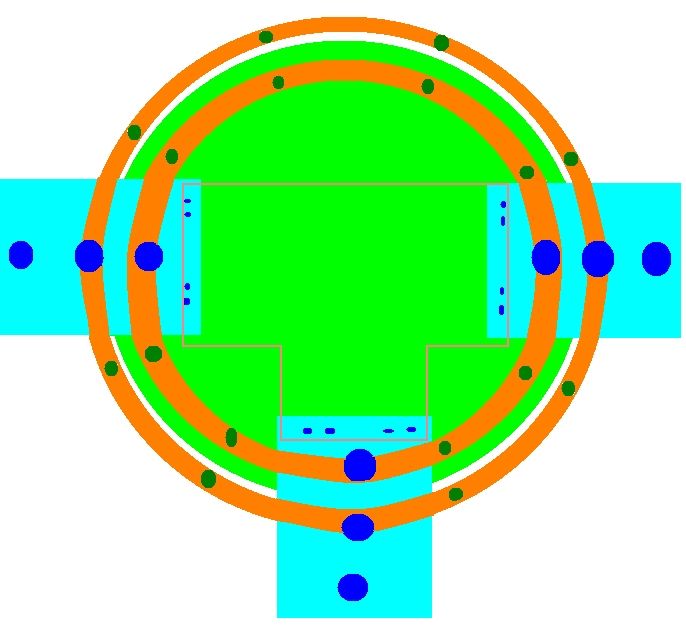

Apologies for the terrible sketch.

I thought two concentric copper rings could be used instead. The material could be thick enough to provide some mechanical strength to the IGBT to ring cap connection. Maybe 4mm thickness or so?

Also with the driver PCB under the ring cap the whole controller enclosure could be about one third smaller.

In the sketch the IGBT's (blue) mount to the base heatsink, then the two rings of copper (orange) bolt to them, then the ring cap (green) mounts on top of the rings.

The thickness of the ring material could be increased to provide more mechanical strength and the inside/outside diameters of the rings changed to provide increased current flow area.

Hopefully the polarities work out ok, i was just basing it off of some of the photos of the controller not the schematic.

The positioning of the IGBT's could be moved a bit to allow for a rectangular PCB.

Or the IGBT's at East and West could be moved to SE and SW making the output connections easier as long as the current flows still work out ok. I just set them at east west and south so that they remained square to each other.

Using the rings would also give much larger clearances between conductors. The rings could be powder coated if required (not where the bolts go though) to increase the electrical insulation.

The PCB has all the space to the north that it can be expanded into if required to make getting at the low voltage connections easier.

What do you think?