06-23-2009, 09:43 PM

06-23-2009, 09:43 PM

|

#1801 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Hey Royal! That would be great! I have the drawings of the bus bars, but they were chosen based on the free copper bars I got from wherewolf (on ecomodder, not a real werewolf). I think there are a few modifications necessary. I'll try to come up with what it would be in general. Drawings for the heat spreader, and for the bus bars. Thank you!

Thank you, Watt-A-Mezz! Now, if anyone wants to buy them from Digikey and have them shipped here, I can send that person over $17.00 from Paypal to offset the cost of the caps. When I add the poly caps, that will increase the ripple current by 5 amps per poly cap, so maybe that would make everything fine with the 470uF caps?

I think I'm going to use the 470uF caps with 3 of the polypropylene caps, which add about 15 amps of ripple current ability.

Last edited by MPaulHolmes; 06-24-2009 at 12:31 AM..

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

06-24-2009, 02:58 AM

06-24-2009, 02:58 AM

|

#1802 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2009

Location: Maine

Posts: 26

Thanks: 0

Thanked 1 Time in 1 Post

|

Quote:

Originally Posted by MPaulHolmes

I think I'm going to use the 470uF caps with 3 of the polypropylene caps, which add about 15 amps of ripple current ability.

|

Paul, what size are those polypropylene caps? that,s a lot of ripple current per cap; Ive been looking at aluminum caps at over 1000MFD to get that level of ripple current absorption. |

|

|

|

06-24-2009, 03:07 AM

06-24-2009, 03:07 AM

|

#1803 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

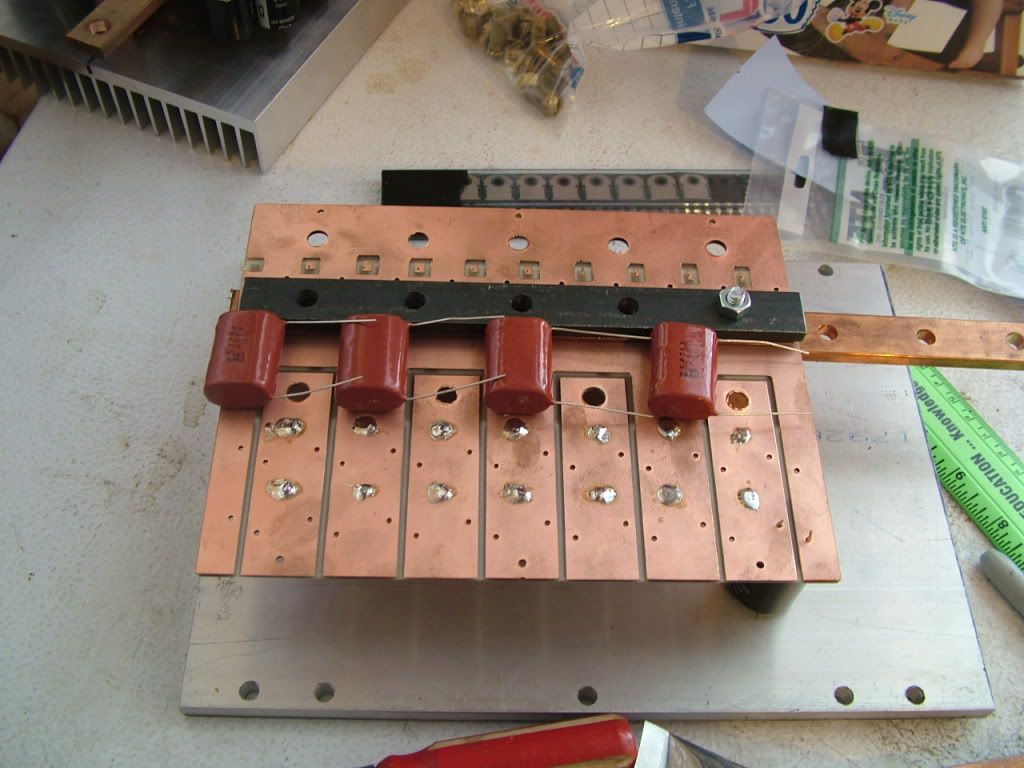

They are 4uF 250v (tiny, huh! But they look huge!). Their esr is very small, and they are excellent at absorbing voltage spikes. I don't know why they increase the ripple current so much. Maybe because they smooth out the spikes, it makes it easier on the aluminum electrolytic caps. Here's a picture of 4 of them:

|

|

|

|

06-24-2009, 12:34 PM

06-24-2009, 12:34 PM

|

#1804 (permalink)

|

|

Joe

Join Date: Feb 2009

Location: phx

Posts: 260

Thanks: 0

Thanked 48 Times in 38 Posts

|

Quote:

Originally Posted by MPaulHolmes

I don't know why they increase the ripple current so much.

|

Not sure if you were really looking for an answer, but this is what i've gleaned from discussions on the EVtech and EVDL.

I think it has to do with temperature - too much heat generation causes the temperature of the caps to rise which decreases their expected life. lower ESR means lower heat generated, so you can pull more amps from it.

Apparently one of the reasons using many smaller caps have a higher combined ripple current rating than one large cap is because the larger surface area. More surface area means the caps are easier to cool. cooler operation means more ripple current capability.

Like you, I've decided to add a couple of low ESR caps (film, i think) to my charger design. i'm still in the process of laying everything out on a PCB, but i hope to have results soon! |

|

|

|

06-24-2009, 01:04 PM

06-24-2009, 01:04 PM

|

#1805 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Hey Joe! You are doing PCB layout! awesome! This is so exciting!

I got the money necessary for the fancy caps for Ben's controller from wherewolf and watt-a-mezz! Yes! No compromises on this one, Ben! (well, the aluminum heat spreader. hehe)

Thank you wherewolf and watt! I'm going to order them from Digikey. Also, the 2 control boards came last night! I need to add a couple components today to the boards, like voltage spike suppression diodes to protect the mosfets' gates.

|

|

|

|

06-24-2009, 01:20 PM

06-24-2009, 01:20 PM

|

#1806 (permalink)

|

|

Joe

Join Date: Feb 2009

Location: phx

Posts: 260

Thanks: 0

Thanked 48 Times in 38 Posts

|

Quote:

Originally Posted by MPaulHolmes

Hey Joe! You are doing PCB layout! awesome! This is so exciting!

|

I agree! i figured the cutting board and web-o-wire mess was way too amateur. now that my components are pretty much nailed down, I think we can be a little more professional! |

|

|

|

06-24-2009, 01:26 PM

06-24-2009, 01:26 PM

|

#1807 (permalink)

|

|

EcoModding Lurker

Join Date: Feb 2009

Location: MO

Posts: 37

Thanks: 0

Thanked 3 Times in 2 Posts

|

Quote:

Originally Posted by MPaulHolmes

|

No music to go along with your capacitor conga line?

|

|

|

|

06-24-2009, 03:17 PM

06-24-2009, 03:17 PM

|

#1809 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2009

Location: Maine

Posts: 26

Thanks: 0

Thanked 1 Time in 1 Post

|

Quote:

Originally Posted by MPaulHolmes

They are 4uF 250v (tiny, huh! But they look huge!). Their esr is very small, and they are excellent at absorbing voltage spikes. I don't know why they increase the ripple current so much. Maybe because they smooth out the spikes, it makes it easier on the aluminum electrolytic caps.

|

Wow that's impressive for such a small uF.

Something I am confused by; I would think that ESR and ripple capacity would directly correlate to each other for the same ratings on voltage and MFD capacity, but looking at numerous data sheets, it seems that they don't?

I must be missing something here.

I think you are right though about the spikes, I think that these are better suited to handle squelching the high frequency harmonic ringing from switching, and the higher capacity aluminum caps are better suited for smoothing the ripple from the root switching frequency.

Now I am rethinking about my capacitor order for my set up.

I am curious, is there a guide line for a ratio between controller current capacity and its capacitor bank ripple capacity and it's total MFD capacity? th would be so helpful.

I have a felling that I am going over board on MFD capacity and maybe a little low on ripple capacity. |

|

|

|

06-24-2009, 07:06 PM

06-24-2009, 07:06 PM

|

#1810 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

|

|

|

|

|