Hey Alvin! It's only the new software that does the new way of blinking fast when there's a problem. I can mail you a chip if you want.

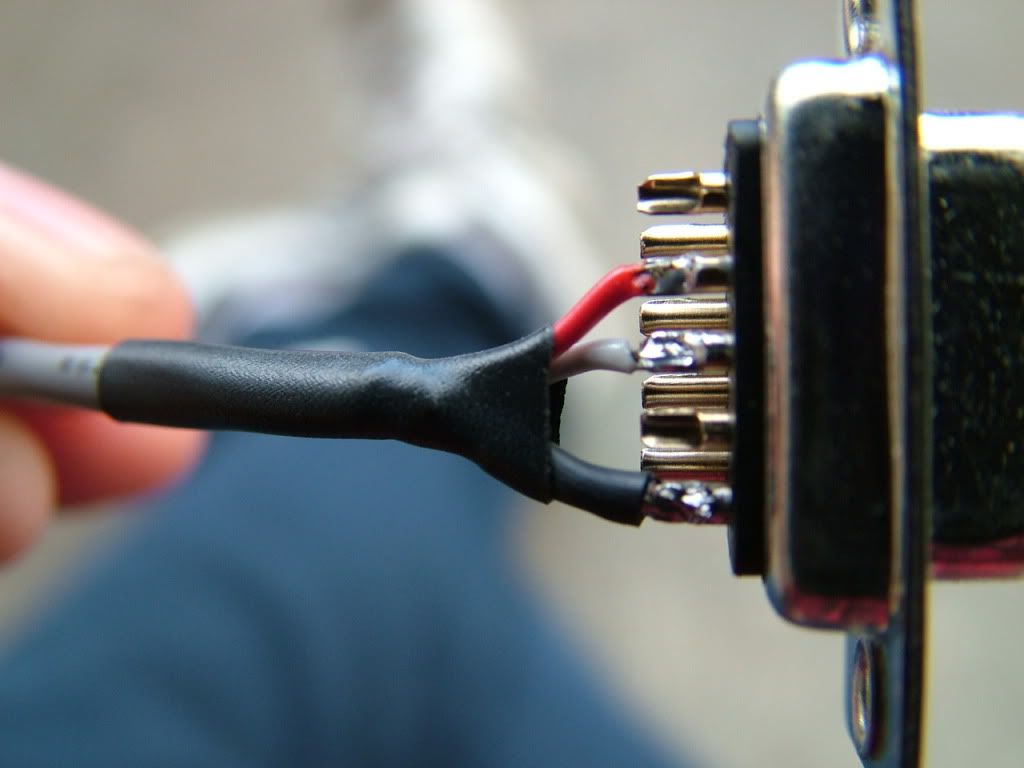

To make use of the reprogrammability, you would need a serial plug like the following:

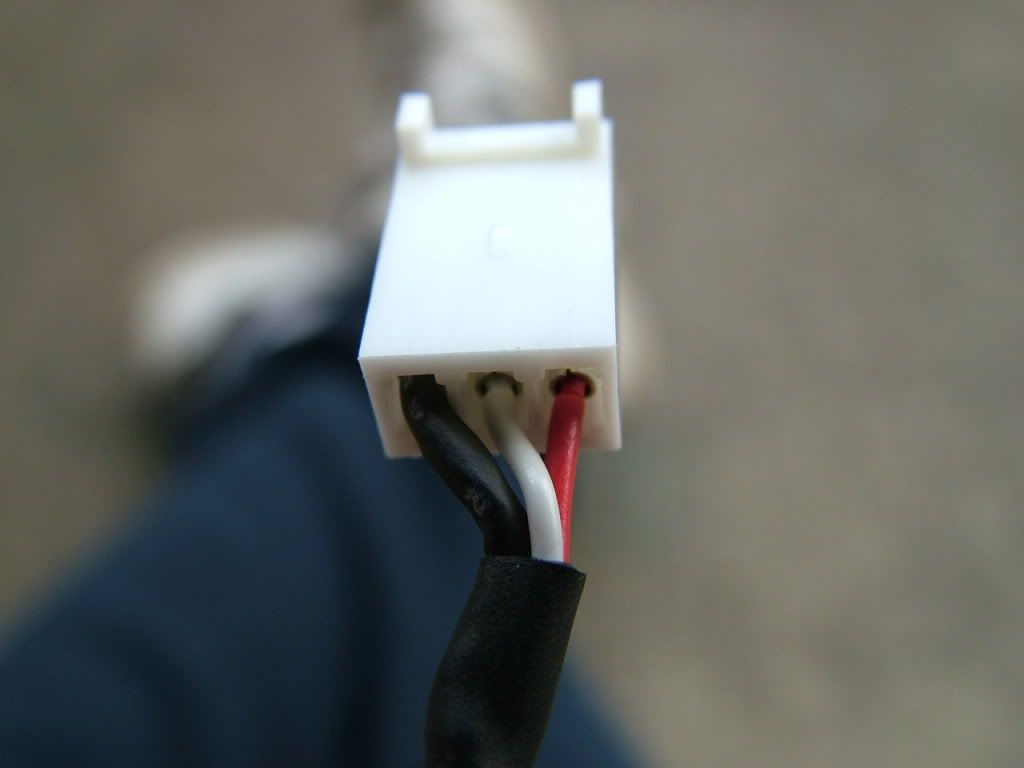

Here's how the other end should look (that goes into the control board):

It's easier just to solder the 3 wires right into the control board though. I think the serial plug thing (it probably should be female) is maybe $0.50 or so at an electronics store. It's really annoying soldering the stupid wires onto those little soder cups. It's easiest to first fill up those little cups on the serial plug, and then push the wire onto the solder. Then the wire melts right onto the little cup.

It might be around the 25th of this month before we get it mailed out. (payday hehe)