05-06-2016, 06:37 PM

05-06-2016, 06:37 PM

|

#51 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,404

Thanks: 24,471

Thanked 7,410 Times in 4,800 Posts

|

nest

Quote:

Originally Posted by freebeard

Could you turn the underbody upside down and nest it underneath the upper body?

|

If I got as far as a hollow shell for the upper body there'd be a slim chance that when 'stacked',their vertical height would fit in under the garage roof in the same bay.

But I'm not optimistic enough to believe that I'll get any further along than a male plug for any of these body parts.

As 'solid' structures,with all the internal bulkheads/stringers/formers/foam/Bondo/ 'n glass,there won't be any space inside them,excepting the bottom,which will have holes to accept the four wheels.

To make everything hollow would require 2-extra generations of fabrications:Mold and wet layup.

If it was going to be a 'real' vehicle it would be worth the effort,but not for a wind tunnel model-only build.

As it is,the parts will have just enough clearance to fit in the bed without chafing one another over the 5,000+ mile journey and still leave me room to sleep inside the rig,which I'll need to do for most of the trip.(Layne offered to store the model for me after testing but I won't be passing through Ogden on the way back from the west coast).

I'll have to leave the more exotic builds to the thousandaires and millionaires.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

05-06-2016, 09:40 PM

05-06-2016, 09:40 PM

|

#52 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,992

Thanks: 8,226

Thanked 9,000 Times in 7,434 Posts

|

I'm for formless construction.

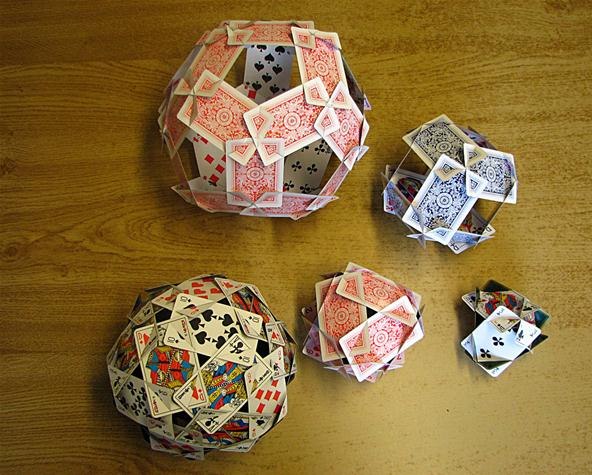

I'll use playing cards as an example. Take a stack of cards and cut slits in the corners. Lay them out contiguously in the shape desired. Tighten them up, lapping the edges and pinwheeling the corners. Your shape may dictate some cards lap more or less than others.

A rough male form like an eggcrate is sufficient, but if the edges are calculated with sufficient accuracy then it can all be done with math. Else the lower form could stay in place, but the upper one would need to be hollowed out. How high on the body will the split be?

I'm thinking about offering up all my illiquid capital to help a niece with her legal woes. Maybe I can take a bus to Utah and spectate.

|

|

|

|

|

The Following 2 Users Say Thank You to freebeard For This Useful Post:

|

|

05-07-2016, 01:48 PM

05-07-2016, 01:48 PM

|

#53 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,404

Thanks: 24,471

Thanked 7,410 Times in 4,800 Posts

|

formless

Quote:

Originally Posted by freebeard

I'm for formless construction.

I'll use playing cards as an example. Take a stack of cards and cut slits in the corners. Lay them out contiguously in the shape desired. Tighten them up, lapping the edges and pinwheeling the corners. Your shape may dictate some cards lap more or less than others.

A rough male form like an eggcrate is sufficient, but if the edges are calculated with sufficient accuracy then it can all be done with math. Else the lower form could stay in place, but the upper one would need to be hollowed out. How high on the body will the split be?

I'm thinking about offering up all my illiquid capital to help a niece with her legal woes. Maybe I can take a bus to Utah and spectate.

|

I'm afraid that the stress of trying to learn a new technique like that would probably push me over the edge of sanity.I walk a fine line as it is.

The laser stereolithography would do this,but I don't think that I qualify as a candidate.

Adam Smith said to build it at home unless outsourcing was cheaper.That would be in the tens of thousands of dollars,so it looks like more home brew for me.

If you can make it out to Ogden,dinner's on me.Gary found a local Mexican joint that,while not the Salt Flats Cafe,does have a pretty tasty dish!

Also,you might think of some things to test for at the tunnel that my pea brain evades.

Three heads are better than one!

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

05-08-2016, 01:21 PM

05-08-2016, 01:21 PM

|

#54 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,992

Thanks: 8,226

Thanked 9,000 Times in 7,434 Posts

|

Quote:

I walk a fine line as it is.

|

So say we all. |

|

|

|

05-19-2016, 01:45 AM

05-19-2016, 01:45 AM

|

#55 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,992

Thanks: 8,226

Thanked 9,000 Times in 7,434 Posts

|

I may or may not have a car running in September; but I have a chassis for a 1/3 scale model! Pic can follow after I find my USB cable.

It's a control bar off a sailboard. Made of 1 1/4" aluminum tube; 80" long by 23" wide. max camber is somewhere about 35%. Fineness ratio is 3.65:1. Perfect for the model of my 21ft motorhome.

I took it into the office at the recyclers and asked for a price. They looked it over and said $10, and I took a Veteran's discount. When I got it home and took a bunch of paracord off, there was a $20 price on it nobody had seen. Score.

Two crossbars for axles. Two triangular scraps of ABS I already had are just big enough for bellypan material.

Edit: An example from a how-to page to help with the playing card analogy:

http://mathcraft.wonderhowto.com/how-to/make-platonic-solids-out-playing-cards-0130512/

http://mathcraft.wonderhowto.com/how-to/make-platonic-solids-out-playing-cards-0130512/

Last edited by freebeard; 05-19-2016 at 02:57 AM..

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

05-19-2016, 01:57 PM

05-19-2016, 01:57 PM

|

#56 (permalink)

|

|

Cyborg ECU

Join Date: Mar 2011

Location: Coastal Southern California

Posts: 6,299

Thanks: 2,373

Thanked 2,174 Times in 1,470 Posts

|

Quote:

Originally Posted by freebeard

|

With the right materials (perhaps more rigid that playing cards), good calculations (which could be hard without experience), and a good process with resin and fiberglass, a modder could make some unusual and effective compound curves for aero features using this interlocking cards technique, no? Idle wondering. Cool edit though.

__________________

See my car's mod & maintenance thread and my electric bicycle's thread for ongoing projects. I will rebuild Black and Green over decades as parts die, until it becomes a different car of roughly the same shape and color. My minimum fuel economy goal is 55 mpg while averaging posted speed limits. I generally top 60 mpg. See also my Honda manual transmission specs thread.

|

|

|

|

05-19-2016, 07:01 PM

05-19-2016, 07:01 PM

|

#57 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,992

Thanks: 8,226

Thanked 9,000 Times in 7,434 Posts

|

My wondering isn't idle, it's rampant.

The Platonic solids were done with interpenetrated cards (to show off a bit?). If each had a small slit in each corner and they were glued or spot welded along the edges, that would produce a continuous surface. In lieu of calculations, I can just pick dimensions off the 3D model in the picture. Any two points are measurable.

Rather than fiberglass, highly-tempered aluminum sheet that would never form a compound curve would be my choice. For fiberglass, I'd go inflatable. |

|

|

|

|

The Following 2 Users Say Thank You to freebeard For This Useful Post:

|

|

05-20-2016, 05:31 PM

05-20-2016, 05:31 PM

|

#58 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,992

Thanks: 8,226

Thanked 9,000 Times in 7,434 Posts

|

Found the cable.

ABS is marked for cutting. And the search is on for a presentable set of 10" wheels. |

|

|

|

|

The Following 2 Users Say Thank You to freebeard For This Useful Post:

|

|

06-25-2016, 01:24 PM

06-25-2016, 01:24 PM

|

#59 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,404

Thanks: 24,471

Thanked 7,410 Times in 4,800 Posts

|

mini update

*2-weeks ago I bought a gallon of Tractor and Implement paint on sale ($25) at Tractor Supply.It's an enamel system which can be reduced for spraying,and has a catalytic hardener available as well.

*This last Wednesday I went to Mineral Wells a day early,to take advantage of the Senior,10%-off discount at Sutherland's.

I got enough aluminum valley flashing (25-ft X 24") and edging to do half the truck.

And some 3M blue tape.

We've lost our 'low' temperatures and I don't foresee any opportunity to do much in the way of composites.It'll be wood skeleton and aluminum skin 'n lots of pop rivets.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

06-25-2016, 04:29 PM

06-25-2016, 04:29 PM

|

#60 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,992

Thanks: 8,226

Thanked 9,000 Times in 7,434 Posts

|

Youtube can show you how to make a spot welder out of an old microwave oven. With a 2-3' throat you could spot weld the whole thing. It would go faster than all that drilling and riveting (once the spot welder is made).*

Absent a female mold, the composite would require a lot more finish work than aluminum. Will it all be painted white?

_______

I've got 3 toddler bike wheels, and I'm thinking about something like all-thread or a threaded rod for the front axle. Maybe frame it with welding rod and fill with luan paneling triangles finished with aluminum tape.

You can see in the pic at Permallnk #59 there are removable straight sections before the rounded tail. Do you think I should Vee them together and drop the rounded section? A cut and two holes and I can make them any length for a fineness ratio between 3.14 and 3.72. Isn't 3.79 optimal?

*Maybe you should ignore that, will you be riveting aluminum to steel and/or wood?

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

|