(Update from last time - the rectangular LEDs aren't very bright. I'm going to try pointing cylindrical LEDs straight at the logo instead.)

The project progresses!

I had a friend cut out the main hunks of plexiglass on his work laser. I tried cutting the .22" thick acrylic on the 25 watt laser, but it just wasn't powerful enough to do it without significant smoke, melting, and other issues. He offered just to cut it for me, so I e-mailed him my Adobe Illustrator file and went from there.

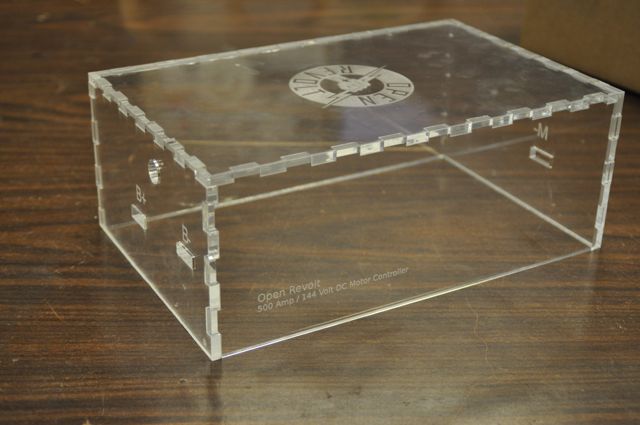

I got the cut pieces back the other day and test fit them. Laser-cut fit was fantastic! Parts went together just like a jigsaw puzzle!

I did sand off the very bottom edge of the one end, as it hit wierd on the heat sink. I also trimmed part of the board on the controller because it stuck out a bit. Heck, the whole controller is sort of out of square!

I put the cut pieces into the laser and engraved the Open Revolt logo into the middle. (Took about 45 minutes - 30% power, 3-passes....)

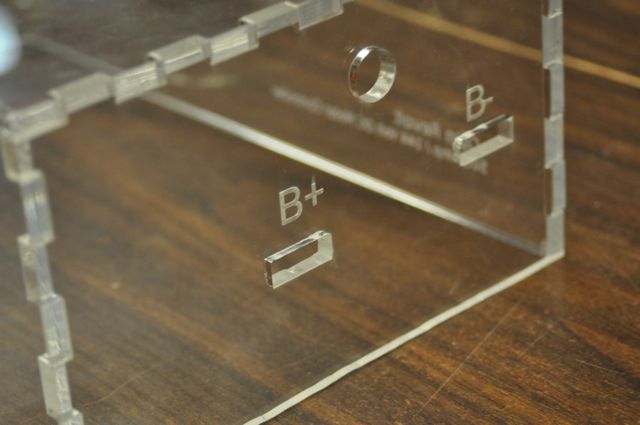

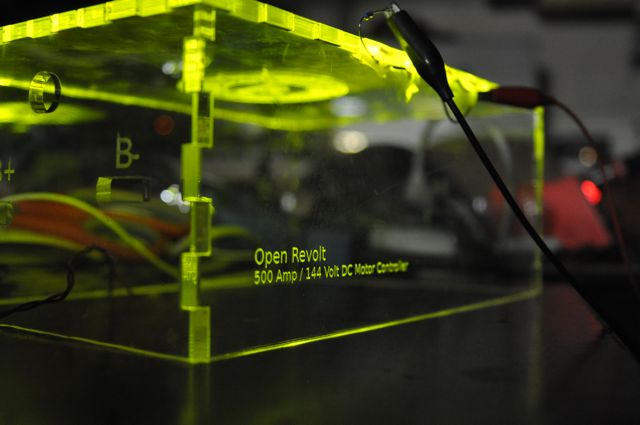

I then engraved the bus bar marks on the ends and "Open Revolt Motor Controller" on the one side.

I've glued the case together as much as I dare to right now. Since bus bars stick out both ends, the whole case does NOT just set over the top of the controller - the end caps have to slide on OVER the bus bars. I decided to glue the top, two sides, and the M- ends. That leaves the end with the B+/B- loose. I should be able to put on that piece and then slide everything else on from the M- end.

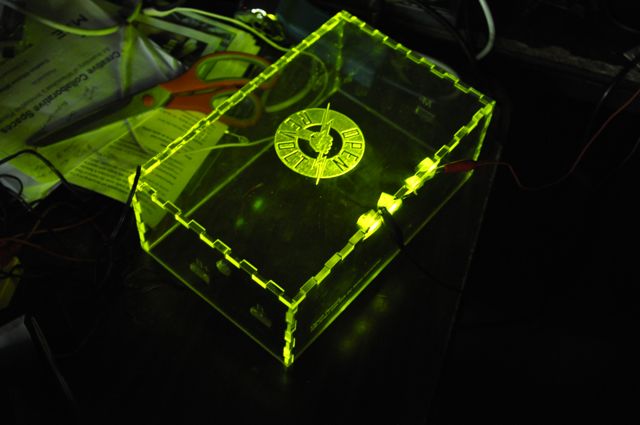

I also got to play around with some LEDs. The etching looks AMAZING when edge-lit with LEDs, but only in the dark.... With the lights on, it barely reads.

After fiddling with the LEDs a bit, and talking with some of the guys, I decided that I need to use some other, higher power, LEDs. I have also been trying to figure out from the start HOW to attach LEDs to the case and MAKE THEM LOOK GOOD! LEDs usually use a resistor for every two or three LEDs on a 12V system. So, I need at least 4 LEDs, 2 resistors, and some bits of wire, (all with my icky-looking soldering skills) mount them to the case AND make them look good!

Some green LEDs that I found were actually pretty small - about 1/8" in diameter. It seems that I could drill a hole in the case, and point them right into there. Except that plexiglass is so brittle, and the holes would be really close to the edge!

I did some test drill in some scrap material, and found that I could cleanly drill a hole that the LED would fit in.

However, I still do NOT want to wreck my nice end cap that somebody else was nice enough to laser-cut for me!

So, here's what I'm leaning towards right now.....

I will cut ANOTHER piece of plexiglass, drill the holes for the LEDs in that, and then glue it to the end cap when all done.

That way, if I mess up, so what. I can make another. Also, I was thinking that maybe I make a spacer and sandwich together that piece of plexi with a cover, so that it covers the resistors and LED power wiring. Might give it a nice finished look, and the "LED Section" will be a stand-alone, removable unit.