01-30-2012, 02:00 AM

01-30-2012, 02:00 AM

|

#31 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Contactor

I won an eBay auction today for an SW-200 contactor with a 12V coil. A never used part from a stalled EV project. The specs I can find are 250A continuous, 360A peak and 1500A rupture. This one has the "blowouts", whatever that means. Sounds awesome, whatever it is. $42 including shipping. I'm pretty happy about that!

Here is my current battery "array" in the garage, all nine floodies hooked together in parallel on a 2A charge, sitting at 13.3V. The AGMs are not hooked up because they don't self discharge like floodies do.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

02-22-2012, 04:09 AM

02-22-2012, 04:09 AM

|

#32 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

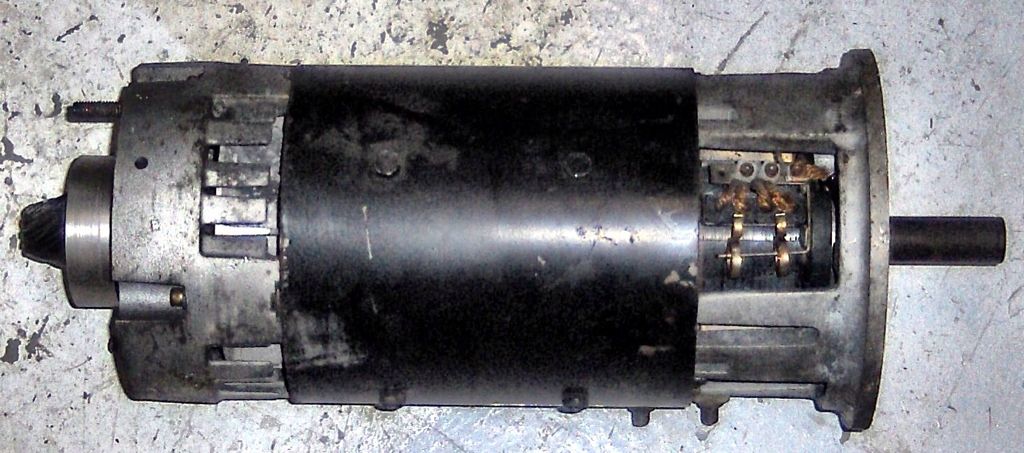

I finally have a line on a motor - the last major piece of the puzzle. I have been searching forklift companies for a while now, but the answer I usually get is that they don't keep motors because they are sent back to the manufacturers as cores. One local company had a bunch of motors but they were either much too big or much too small.

The motor in question is a Prestolite MVX-4003. I am told that it is the same motor that Jet Electrica used in the early 80's in Ford Escort conversions. 18 HP continuous and about 100 lbs. 7-1/2" diameter and quite long. It should do just fine! I think I will buy it tomorrow.

It's being sold by a company somewhere on the east coast. Here is the picture I have:

|

|

|

|

02-22-2012, 07:45 AM

02-22-2012, 07:45 AM

|

#33 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

The diameter is a bit on the small side, but the weight makes me think there is enough motor there to handle some good power. 18hp continuous is pretty decent too.

Are there going to be any problems with it being too long? I know that was almost an issue in Ben Nelson's ElectroMetro.

|

|

|

|

02-22-2012, 12:34 PM

02-22-2012, 12:34 PM

|

#34 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Quote:

Originally Posted by Daox

The diameter is a bit on the small side, but the weight makes me think there is enough motor there to handle some good power. 18hp continuous is pretty decent too.

|

That's what I was thinking too. I was mostly going by weight in all my motor searching, which tends to confuse forklift guys a bit.

"What voltage do you want?"

"Um....that doesn't really matter - I want it to be around 100 lbs."

(Blank stare in return).

My favorite comment from one guy was, "it would be way better to go with an AC motor. Just buy a big inverter - it will be way cheaper."

"Um...yeah....no."

Quote:

|

Are there going to be any problems with it being too long? I know that was almost an issue in Ben Nelson's ElectroMetro.

|

Yeah, I remember reading about the hammering that Ben had to do. Thanks for reminding me. I just went out with a tape measure and I have a good 19-1/2" from the bell housing to the opposite side of the engine bay. I didn't get a length measurement on this motor, but with a ruler on my computer screen and some quick calculation (knowing the diameter), it is just over 18-1/2" long from the output side of the case to the end of the drive gear thingy on the other side. With an inch to play with it should fit. SHOULD.

I do have a huge hammer, just in case.

UPDATE: I ordered the motor this morning from EV Corp. $388 + shipping. I can't wait to tinker with a real live motor!

Last edited by mechman600; 02-22-2012 at 02:15 PM..

|

|

|

|

02-26-2012, 06:04 PM

02-26-2012, 06:04 PM

|

#35 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

More eBay purchases.

Aftermarket 12V vacuum pump that's meant for a Dodge or Ford diesel. The seller says it reaches a certain vacuum and then shuts off. I will have brakes after all! $65.

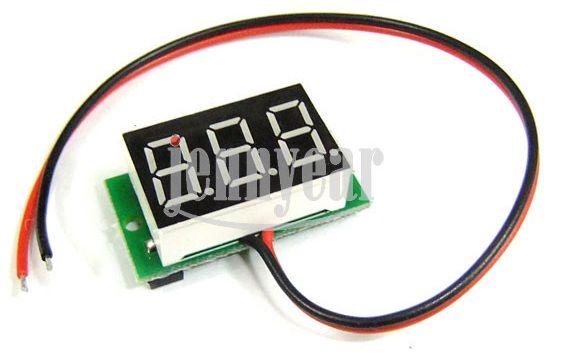

(6) 4.5-30V panel voltmeters for individual battery monitoring. Seeing as how I am using a mish-mash of old batteries, I want to be able to sort out the good ones from the bad ones. $29.16

I will install them into a removable/diagnostic panel for battery diagnostics, using this connector that I mentioned earlier:

0-100V panel voltmeter for monitoring system voltage. Most meters like this are 3-wire (+ 12V wire, - 12V wire and measuring wire) which is no good for my purpose. This one is a 4-wire meter (+ 12V wire, - 12V wire, measuring + and measuring -), which is better suited for a pack voltage meter. $6.29

I also got a bag full of surplus/unneeded electrical bit from work yesterday: relays, switches, fuse holders and various connectors. FREE.

Last edited by mechman600; 02-26-2012 at 06:16 PM..

|

|

|

|

|

The Following User Says Thank You to mechman600 For This Useful Post:

|

|

03-19-2012, 02:57 PM

03-19-2012, 02:57 PM

|

#36 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Motor Test

I finally went across the border to Blaine, WA to pick up the motor. That's where I send most things, because it is way cheaper to ship to a US address and bring it into Canada myself. I have a Nexus card, so it doesn't take long at all - maybe an hour in total, including the drive and including filling up with cheap American gas!

I got home and quickly hooked up the motor up to a battery. At 12V, it BARELY turns. At 24V, it spins at about 120 rpm. At 48V, it spins at maybe 1000 rpm, but that's just a guess. What the heck? That can't be right. The brushes are advanced to spin the correct direction, and reversing the direction yielded a much slower speed. Shouldn't this motor spin up like crazy on 12V and spin out of control and blow up on 48V with no load? To be honest, I am connecting the armature and field with a 10 gauge wire, but I would think this should be enough for no-load current testing, no? The wire wasn't getting warm or anything.

HELP!

EDIT: I just heard back from the guy I bought it from. Turns out....it's actually a SEP-EX motor! At least my lack of motor speed is justified. But it still sucks. Now I have a controller and motor not compatible with each other.

Last edited by mechman600; 03-19-2012 at 04:43 PM..

|

|

|

|

03-20-2012, 09:13 PM

03-20-2012, 09:13 PM

|

#37 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Vacuum Pump

Today I tested my $65 Chinese vacuum pump. Not so impressive. It does not turn itself off when it reaches a preset vacuum like the seller said. And it only pulls 13.5" HG of vacuum. Is that enough vacuum for the brakes? Am I going to have to purchase a vacuum switch so the pump automatically turns off? Maybe I will try to hook it up to the brake light switch so it turns on whenever the brakes are applied. I guess this is something I can start testing already.

Oh hate.

|

|

|

|

03-23-2012, 07:54 PM

03-23-2012, 07:54 PM

|

#38 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Motor Test - Take #2

Now that I know that I am dealing with a sepex motor, I gave it test #2 by hooking up the field to 12V and armature to 12V (parallel instead of series). VOILA - the motor spun right up.

Paul at EPC Corp is sending me a "field control module". Basically, it is a constant 12V supply with spike suppression that hooks up the to field to give it a constant voltage, so it will act like a series wound motor when I power the armature with my Alltrax controller (notice the massive spark in the video when I disconnect the field from my power supply - this module takes care of this so I don't fry stuff when I shut it off). Honestly, I am a bit skeptical, but he says it works. It won't have regen braking or make the motor reversible, but that's no problem. Maybe it will open doors in the future if I play around with field voltage on a separate rheostat of some sort. |

|

|

|

03-23-2012, 10:27 PM

03-23-2012, 10:27 PM

|

#39 (permalink)

|

|

Ford Escort 2.0

Join Date: Feb 2008

Location: Alameda, CA

Posts: 240

Thanks: 6

Thanked 27 Times in 24 Posts

|

In series motor, you reverse the motor by changing the field polarity compared to the armature. If you reverse polarity with your 12v battery to just the field (keep the armature the way you have it) it should run in reverse...

__________________

|

|

|

|

03-23-2012, 11:01 PM

03-23-2012, 11:01 PM

|

#40 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Quote:

Originally Posted by TomEV

If you reverse polarity with your 12v battery to just the field (keep the armature the way you have it) it should run in reverse...

|

Yes. I did that to see how the brushes are timed. It spins the same speed either way, so I am assuming that the brushes are neutral.

What I meant was this "field control module" is a very simple device with no other purpose than supplying 12V and suppressing the spike when turned off. I am a bit skeptical that it will work well because if it was this easy to control a sepex motor with a PM/series controller, you would see it all over a Google search, but you don't.

I am also starting to think that my motor is too small. It just looks...well..small.

|

|

|

|

|