01-08-2012, 08:55 PM

01-08-2012, 08:55 PM

|

#11 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Thoughts on higher voltage

The general consensus is that a regular old forklift motor can take 72V without [quickly] exploding. Is this because of the neutral brush timing? I wonder if you can feed it more V/speed if you advance the brush timing....

I don't think 12 batteries (series/parallel) will fit into an MX-3 without serious imagination. Six batteries probably won't give me my required range. The alternative is just going with as many as I can fit - whether 7, 8, 9, 10....whatever. But that means voltage will have to be higher than 72. I guess with a higher voltage system I can always limit V to the motor.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-10-2012, 04:38 AM

01-10-2012, 04:38 AM

|

#12 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Controller Max Voltage Question

Question: Alltrax lists the max voltage of the 7245 controller as 90V. Assuming that open circuit fully charged voltage will be 12.8V per battery, this makes an "84V" string 89.6V, just under max. Is it possible to actually run 84V with this controller? Sure, with some surface charge it will be over 90V, but couldn't you just turn the electric heater (or any load) on for a minute to get rid of the surface charge?

Just asking.

|

|

|

|

01-10-2012, 08:55 AM

01-10-2012, 08:55 AM

|

#13 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Western Wisconsin

Posts: 3,903

Thanks: 867

Thanked 434 Times in 354 Posts

|

A fully charged 12v battery is going to be closer to 13 or even 13.4 if it just came off the charger.

I would also opt for a higher amp controller then 450 amps if you are only running 72v then you end up with 32,000 watts that you can pull, I only say this because people complain about their EV being a bit sluggish or slow when their controller is to small, my EV is 1,400 pounds and has the Altrax 4865 in it, so even tho it's a 48v controller I can put 650 amps or 31,000 watts to the motor when needed and I've seen it happen, not for very long but for long enough that I was glad that I had a controller that could handle that many total watts.

As for running the motor at a higher voltage, pretty much everyone says it's fine to do, that over speeding the motor and over heating it are the main things you need to worry about and both of those are easy to prevent/control, for the over speeding of the motor just figure out how fast it's spinning in each gear, and for over heating, a small squirrel cage fan and a short piece of heater duct from the auto part store should force cool it, add an air filter in there and your motor will be really happy, if you want to keep your motor under a set voltage then figure out what voltage it takes to go the speed you want and don't go faster then that! you could have a 300v battery pack but if you only ever drive 45mph and it only takes 60v to drive that speed then the speed controller is limiting the voltage to the motor to only allow it to spin fast enough to go that speed, the advantage of that higher voltage battery pack at that point is that your line loss in all of your wiring and battery interconnects is less, so popular opinion is that the highest voltage battery pack that you can get away with tends to be the best option as long as the batteries are not getting so small that they can't handle the load.

|

|

|

|

|

The Following User Says Thank You to Ryland For This Useful Post:

|

|

01-10-2012, 02:23 PM

01-10-2012, 02:23 PM

|

#14 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Thanks, Ryland. I believe that's the second time you have advised to go bigger than the Alltrax. Advice taken. I guess its a "being cheap" thing. But the controller is something that I shouldn't be cheap with if I want to be happy with the final result.

I am interested in Paul & Sabrina's controller, but I have no electronics experience and my soldering usually looks like bird poo. Maybe it's my giant soldering gun. Maybe with some practice and a better iron I could do it. I do know how to follow instructions and figure stuff out (being a diesel engine tech by trade kind of makes that a necessity!) Like I said above, having even a 72-120V controller vastly opens my options for battery arrangement. Found another battery? Add it to the string and go faster!

As far as motor heat goes, I will probably find a place or make a holder to mount the ICE coolant temp sender somewhere in the motor at the commutator end. If I see the gauge move at all, I back off.

|

|

|

|

01-10-2012, 03:21 PM

01-10-2012, 03:21 PM

|

#15 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

If Ben can fit 12 batteries in his Geo Metro I'm sure you can get 12 batteries in an MX3. It might take some cutting and welding, but you should be securing them down solid anyways which will more than likely require welding at the least.

|

|

|

|

01-10-2012, 04:09 PM

01-10-2012, 04:09 PM

|

#16 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Western Wisconsin

Posts: 3,903

Thanks: 867

Thanked 434 Times in 354 Posts

|

For placing the batteries remember that the area where the gas tank is will be open for you to cut in to the floor of the car and drop a battery box down and out of the way, you also will get rid of the radiator, gas engine and a bunch of other stuff under the hood freeing up space up front, of course you need space for the motor and transmission but an electric motor takes up a lot less space then a gasoline engine does.

You might also look at Curtis controllers, they have been around for around 50 years and build some pretty solid speed controllers, because they have been around as long as they have and make speed controllers for all kinds of stuff it can make your head spin a little trying to pick one out and find the best price on it, but if you don't want to build your own then that is another option, otherwise there are some really high end, expensive speed controllers out there by NetGain and Zilla and a few other companies that are not coming to mind right now, just stay away from Kelly controllers unless you like stuff starting on fire.

If you do want to build your own speed controller a good quality electric soldering iron is key, I've used a soldering gun a bunch and never really cared for them, but a soldering iron with a good clean tip and some fine gauge silver bearing solder and you should pick it up quickly.

|

|

|

|

01-10-2012, 04:32 PM

01-10-2012, 04:32 PM

|

#17 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Thanks for the sound advice, guys. I have my eBay app set to notify me when certain auctions come up, "1221C" and "1231C" being two of them. I erased the one for "Alltrax 7245" for now.

I may be bidding on something later today. Muah ha ha ha ha ha...ahem. I DO have some Christmas money to spend.

I looked up specs for the MX-3. Here is a comparison between it and a Metro:

METRO MX-3

Wheelbase 93.1 96.3

Length 149.4 165.7

Width 62.6 66.7

Curb Weight 1808 2443

Cargo Volume 21.9 36.6

What a beast!!

One more question: is it possible to run two controllers in parallel? Like a 48V 600A controller (hooked up to 8 batteries) in parallel with a 72V 450 A controller (hooked up the 8 battery 48V string with an additional 2 batteries in series. Just wondering, that's all. I realize it wouldn't save money. But it would be....well..er..interesting to try.

Last edited by mechman600; 01-10-2012 at 05:03 PM..

|

|

|

|

01-11-2012, 12:17 AM

01-11-2012, 12:17 AM

|

#18 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Western Wisconsin

Posts: 3,903

Thanks: 867

Thanked 434 Times in 354 Posts

|

Quote:

Originally Posted by mechman600

One more question: is it possible to run two controllers in parallel? Like a 48V 600A controller (hooked up to 8 batteries) in parallel with a 72V 450 A controller (hooked up the 8 battery 48V string with an additional 2 batteries in series. Just wondering, that's all. I realize it wouldn't save money. But it would be....well..er..interesting to try.

|

A lot of larger motors have separate field windings so you have a total of 4 studs to hook your electrical cables up to the motor, one pair for the armature and one for the stater, in a series wound motor those windings get wired up in series, now as I understand it you could also power them up using separate controllers like you said, this is kind of how a SepEx motor works only it's all done in a single controller, SepEx motors, if I understand them correctly have a smaller gauge field winding so the part of the controller powering up that winding is lower power and thus cheaper to build in to this single controller, but back to your dual controller question, I think you could get away with two controllers controlling the two parts of the motor and I think it should work, I don't think it would give you a huge advantage and as you said it would have the cost of two controllers, altho they would be smaller controllers, it's not something I would bother trying unless I happen to have two controllers laying around... someday I might be at that point in life.

Check the [EV Tradin post] - Advertisement categories too, I bought my Altrax for my motorcycle on there, I did choose an Altrax for that because it's a much smaller vehicle then a car, I also wanted my motorcycle to be golf cart based, at least in the first incarnation, so that I would know what off the shelf golf cart parts could do, but I was able to get that controller for less then what they sell for on Ebay and I know that from time to time other speed controllers show up, you might also check to see if there are any local EV clubs in your area, a friend of mine is putting together a Nissan 300ZX that he bought from an EV club member and is using a motor and controller that he bought from another EV club member from a project that they gave up on, all brand new parts going in to a car that was an unfinished project as well. |

|

|

|

01-11-2012, 04:22 AM

01-11-2012, 04:22 AM

|

#19 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Thinking too much

Quote:

Originally Posted by Ryland

in a series wound motor those windings get wired up in series, now as I understand it you could also power them up using separate controllers...

|

Thanks. You had me thinking about this all evening, while I was at work, and that's bad.

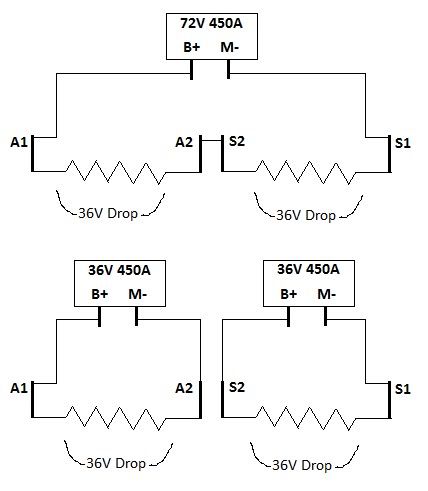

As I see it, two cheaper controllers would make a series wound motor perform like a motor being fed twice the voltage. Let's use 72V and 450A as an example with the motor at the perfect rpm to draw 32.4KW of energy (ignoring battery voltage sag). Two resistors in series, the armature windings and field windings, will have a 36V voltage drop across each of them. This, of course, assumes that they both have the same resistance (which I doubt they do). If they do, the same power and rpm can theoretically be achieved by using two 36V, 450 controllers, one powering the armature and the other powering the field.

Thus, if you have a 36V battery pack and two 36V controllers, could you not get the same performance (speed) as with a 72V pack and one controller? If yes, then BAM!...I just punched a high voltage pack in the face!

I just need to know whether the armature has the same resistance as the field. If nobody knows the answer to this, it would be ridiculously easy to figure out. Somebody go for a drive with your EV and a voltmeter. Measure the voltage drop across the armature vs the voltage drop across the field. Who wants to do this for me?

|

|

|

|

01-12-2012, 04:56 AM

01-12-2012, 04:56 AM

|

#20 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Lots of stuff

I picked up the MX-3 today. I took it through AirCare and it passed with flying colors. It seems kind of pointless, as I plan to rip out the ICE in a few months anyway. Oh well...The AirCare is good for two years so I won't have to worry about it for a while. I asked one of the guys there about EV conversions and with a blank look on his face he said something about calling ICBC (our provincial government run & owned car insurance/monopoly) to straighten it out. I don't have to worry about that for two years at least.

The car actually runs really well. 280,000 km on the odometer. I spend much of the evening fixing burned out exterior lights. It took 2 new headlights (both low beams/daytime running lights didn't work), 4-1157 bulbs, a small clearance lamp bulb and some sanding on some very rusty bulb sockets. It has been sitting in a grass field for a while. Maybe light bulbs don't like grass fields. I am kind of looking forward to testing out my hypermiling skills because this is the first manual transmissioned car I have owned since learning about this new-fangled thing known as hypermiling.

I also removed the driver's side front wheel and rear wheel and drum to check things out. Looks like the brakes were done recently. That's good news.

Here's some pictures:

Yes, that is in fact paint falling off the hood and zip ties holding the front bumper on. It is a $400 car, after all!

It turns out there is WAY more room behind the back seat than I ever would have imagined. Way more than a civic hatchback. Even way more than my wife's Toyota Matrix. Good news for battery storage!

I ordered one of these today:

http://www.amazon.com/Schumacher-SC-...6361551&sr=8-5

I don't have a proper charger to maintain all these batteries I am collecting. I am tentatively planning to eventually buy few more of these for my on board chargers, so I will test this one out before I do.

|

|

|

|

|