10-04-2014, 03:18 PM

10-04-2014, 03:18 PM

|

#1 (permalink)

|

|

Human Environmentalist

Join Date: Aug 2010

Location: Oregon

Posts: 12,906

Thanks: 4,352

Thanked 4,501 Times in 3,462 Posts

|

I want to kill my alternator!

I want to kill my alternator, but not permanently. There was another thread on here where someone experimented with an alternator kill switch, and accidentally killed their alternator. I think they grounded a signal wire and it ended up frying something. I'd like my alternator kill switch to also be capable of reviving the charge capabilities.

My car is an Acura TSX (Euro Honda Accord). Any thoughts on how to wire in an alternator kill switch without actually destroying the charging system? Do you have experience with alternator kill switches in a Honda?

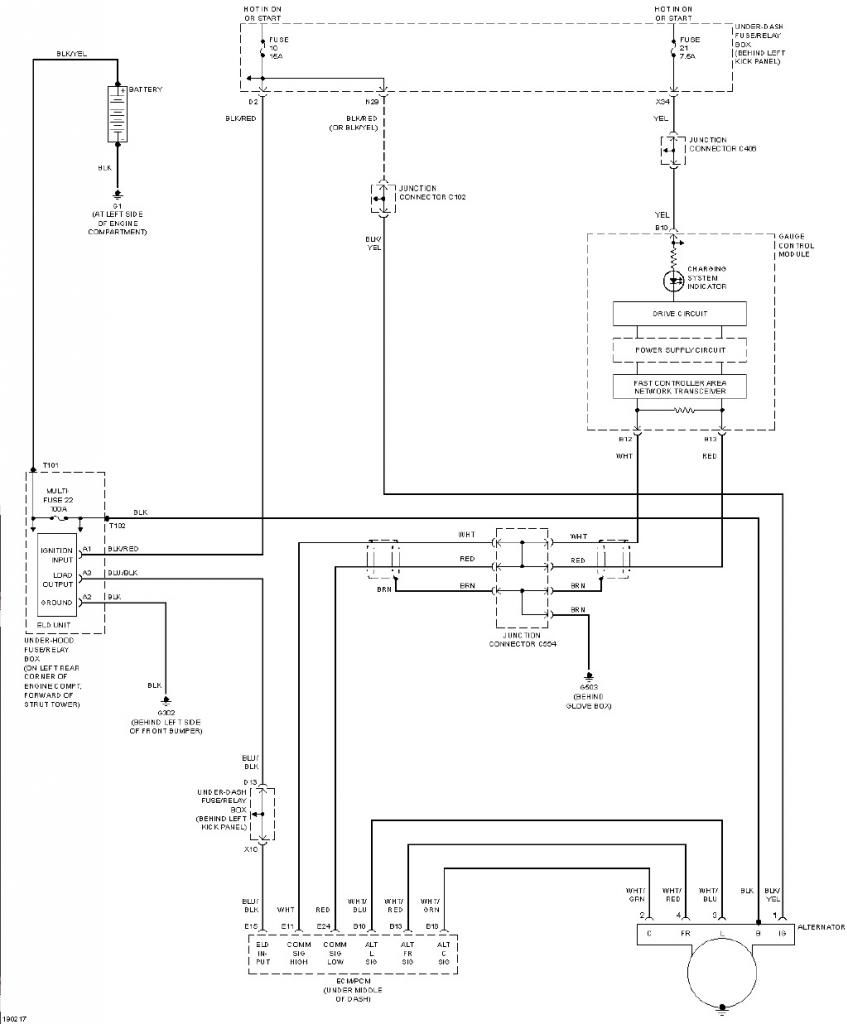

Here is the charging system diagram of the TSX. Apparently it does have an ELD. If the image is too small to read, let me know and I'll see if there is a way to upload something larger.

Last edited by redpoint5; 10-04-2014 at 03:44 PM..

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

10-04-2014, 09:01 PM

10-04-2014, 09:01 PM

|

#2 (permalink)

|

|

Master EcoModder

Join Date: May 2012

Location: USA

Posts: 2,643

Thanks: 1,502

Thanked 279 Times in 229 Posts

|

|

|

|

|

|

The Following User Says Thank You to Cobb For This Useful Post:

|

|

10-04-2014, 10:17 PM

10-04-2014, 10:17 PM

|

#3 (permalink)

|

|

Too many cars

Join Date: Oct 2009

Location: New York State

Posts: 1,616

Thanks: 1,364

Thanked 817 Times in 486 Posts

|

Grounding the alternator's C terminal will put the alternator in the 12.5v low output mode. I keep mine there most of the time. I have disconnected the wire to the ECU and ground the C terminal manually through a resistor. The resistor might not be necessary, but I put it there anyway. I might've used a 100 ohm, I'm not sure. The alternator won't be totally off if you do this, but it won't be working as hard either. You'll want a voltmeter in the car. Running too high of an electrical load in this mode will drain the battery.

__________________

2000 Honda Insight

2000 Honda Insight

2000 Honda Insight

2006 Honda Insight (parts car)

1988 Honda CRXFi

1994 Geo Metro

|

|

|

|

|

The Following User Says Thank You to Gasoline Fumes For This Useful Post:

|

|

10-05-2014, 07:29 AM

10-05-2014, 07:29 AM

|

#4 (permalink)

|

|

Human Environmentalist

Join Date: Aug 2010

Location: Oregon

Posts: 12,906

Thanks: 4,352

Thanked 4,501 Times in 3,462 Posts

|

I've never noticed a fluctuation in voltage; it's always remained at 14.4v from what I recall. I wonder if running a 20% underdrive on the alt has affected the output behavior?

It seems the car already does it's best to reduce fuel consumption if it has the ELD, and even goes into high output mode when decelerating (according the the forum linked above).

Although I read a lot on how to bypass the ELD to run in high output mode, I'm still not any closer to figuring out how to disable the alternator. I figured I could put some massive switch in between the main output wire of the alternator. Any reason why I couldn't just disconnect the output?

I'm quickly loosing steam on this project since there doesn't seem to be a clear way to disable the alternator, and it's already efficient in the first place because of the ELD.

|

|

|

|

10-05-2014, 08:59 PM

10-05-2014, 08:59 PM

|

#5 (permalink)

|

|

performance with economy

Join Date: Sep 2014

Location: melbourne Australia

Posts: 27

Thanks: 0

Thanked 1 Time in 1 Post

|

I have a photo of an alternator (or more precisely generator) delete on one of smoky Yunicks race cars, he dumped the standard engine mounted generator and instead mounted a small generator in front of the radiator complete with a propeller attached. There wasn't an in-car computer to run back then (the 1970s I presume), but there was the ignition system to power. Unfortunately the race scrutineers called this mod "cheating" and wouldn't allow him to run it. Obviously you won't be doing race speeds on public roads, so how effective this would be I have no idea. An existing electric thermo fan might generate some current if wired in correctly to charge the battery rather than drain it.

|

|

|

|

10-05-2014, 09:41 PM

10-05-2014, 09:41 PM

|

#6 (permalink)

|

|

5 pin sensor

Join Date: Sep 2014

Location: Dallas

Posts: 350

Thanks: 38

Thanked 73 Times in 56 Posts

|

Quote:

Originally Posted by redpoint5

I've never noticed a fluctuation in voltage; it's always remained at 14.4v from what I recall. I wonder if running a 20% underdrive on the alt has affected the output behavior?

It seems the car already does it's best to reduce fuel consumption if it has the ELD, and even goes into high output mode when decelerating (according the the forum linked above).

Although I read a lot on how to bypass the ELD to run in high output mode, I'm still not any closer to figuring out how to disable the alternator. I figured I could put some massive switch in between the main output wire of the alternator. Any reason why I couldn't just disconnect the output?

I'm quickly loosing steam on this project since there doesn't seem to be a clear way to disable the alternator, and it's already efficient in the first place because of the ELD.

|

I haven't read to much into the subject but the best solution would be to create an alternator clutch pulley similar to the ac compressor clutch. Since I believe you can remove the alternator pulley you could try to put the compressor clutch style pulley on an alternator. The alternator doesn't have a clutch to determine pulley resistance to belt movement it just regulates current to the battery being produced ... I think

Not sure the dimensions of a compressor clutch but if you could control it with a switch and monitor battery voltage you would see a noticeable gain in mileage during daytime highway driving. You would be going to zero resistance from the alternator

Just a brain storming idea, I would be interested in something simple like that. Because the alternator is mainly a mechanical device there really isn't a feasable way to prevent it from turning mechanical energy into electrical enegergy

__________________

Current: 1997 civic lx

Past: 1998hx/1996hx/1997lx/1997hx Cali/1997hx

OG lean burn member

My civic thread

My civic thread

Last edited by Chrysler kid; 10-05-2014 at 09:48 PM..

|

|

|

|

10-05-2014, 11:28 PM

10-05-2014, 11:28 PM

|

#7 (permalink)

|

|

Human Environmentalist

Join Date: Aug 2010

Location: Oregon

Posts: 12,906

Thanks: 4,352

Thanked 4,501 Times in 3,462 Posts

|

Quote:

Originally Posted by Chrysler kid

... you could try to put the compressor clutch style pulley on an alternator.

...the alternator is mainly a mechanical device there really isn't a feasable way to prevent it from turning mechanical energy into electrical enegergy

|

I like the out of box approach to thinking of a solution.

The alternator can be prevented from turning mechanical energy into electrical by removing the output wire. There has got to be a better/simpler/cleaner approach to switching the alternator on and off though.

I'm attempting to read up on modern alternators. Honda has 4 smaller wires in addition to the large output wire that I haven't figured out what they do. Some probably energize the windings, and I believe 1 of the wires monitors voltage on the battery. |

|

|

|

10-06-2014, 12:07 AM

10-06-2014, 12:07 AM

|

#8 (permalink)

|

|

5 pin sensor

Join Date: Sep 2014

Location: Dallas

Posts: 350

Thanks: 38

Thanked 73 Times in 56 Posts

|

The regulator sends a current to the alternator which creates a magnetic field. You would just need to have a switch between the regulator and the alternator to disrupt the magnetic field.

However it looks like all alternators have internal regulators so you would need to find where regulator output wire is.

__________________

Current: 1997 civic lx

Past: 1998hx/1996hx/1997lx/1997hx Cali/1997hx

OG lean burn member

My civic thread

My civic thread

|

|

|

|

10-06-2014, 03:28 AM

10-06-2014, 03:28 AM

|

#9 (permalink)

|

|

Human Environmentalist

Join Date: Aug 2010

Location: Oregon

Posts: 12,906

Thanks: 4,352

Thanked 4,501 Times in 3,462 Posts

|

I found a very helpful document that describes what each of the 5 wires on the alternator does. From my understanding of the below explanation, it seems there are 2 ways to disable the alternator.

1. Supply 5v on the FR circuit tricking the ECM into thinking electrical demand is zero.

2. Ground the C circuit output.

Quote:

There are five wires connected to the alternator. One wire is power from the fuse box. This wire carries the alternator output current to charge the battery.

The second is power while the ignition switch is on. This circuit powers up the voltage regulator. The third controls the warning light.

The fourth is the charging rate input to the ECM. The fifth is an output from the ECM. This is the control circuit that turns the alternator on through the voltage regulator.

There are a total of three wires to the computer that are involved in the charging system. It is the function of these three circuits that we will discuss.

These three circuits are: The ELD input (Electric Load Detection), the FR input (Charging Rate Signal), and the C circuit output (The wire that the computer uses to turn the alternator on.).

The first of the inputs is the ELD or the electric load detection sensor. This sensor monitors the electrical load on certain circuits. It actually functions as an ammeter. The computer uses this information in conjunction with the FR or charging rate signal in order to control idle speed and whether or not to turn the alternator on or off. The ELD sensor has three wires: battery power from the ignition switch, ground, and the ELD signal wire.

The computer supplies a 5 volt reference signal on the ELD signal wire. This reference voltage can be checked with the sensor unplugged and the ignition key on - engine running or engine off. When you plug the sensor in, the signal voltage will be pulled down depending on how much current is passing through the ELD sensor. You can check this by monitoring the voltage on the ELD wire as loads are turned on or off. For example, with a warmed up engine at idle with all accessories off, there is approximately a 5 ampere current draw. With this amount of current, you should see approximately a 3 volt signal on the ELD signal wire. If you were to turn the heater blower on high, this would create a current draw of approximately 17 amperes. With this type of load, you should see a signal voltage of about 1.8 volts. If the computer detects a problem with this sensor, it will set a Code 20.

Not all of the electrical loads are monitored by the ELD sensor. Battery charging current, the warning flashers, and the com-puter’s memory keep-alive circuit are instead taken into account by the FR signal which we will now discuss.

The second of the inputs is the FR signal, which is the charging rate signal. This signal communicates to the computer on how hard the alternator is working to meet the total electrical needs of the vehicle, including the state of charge of the battery and any loads not directly monitored by the ELD sensor. This signal is a digital signal that varies in pulse width according to the total load on the alternator. The computer supplies approximately a 5 volt reference signal through the FR circuit to the voltage regulator.

The voltage regulator will cycle this signal from 5 volts to approximately 1.2 volts in proportion to the alternator load. For example, with a warm engine at idle and all accessories off, duty cycle should be 30-35% (negative trigger on your meter). Turn your headlights on, and your reading should be 55-60%. Add the rear defroster, and it should be 80-90%.

There are two situations when the FR signal will not be digital. One will occur when the load on the alternator is very high. At this point the signal will be a flat line, non pulsed voltage at approximately 1.2 volts (that is, 100% duty cycle). That should be the lowest reading you should ever have if the system is functional. This signals the computer that the alternator is working at close to maximum output. The second situation will occur if the total electrical load is very low. At this point the FR signal will be a flat line (non pulsed signal) at approximately 5 volts. This signals the computer that the battery is fully charged and that overall electrical demand is low. When this happens, the computer can turn off the alternator through the one computer output, the C circuit. This is the one circuit where the computer turns the alternator on and off.

The voltage regulator supplies an 8.5 volt (approximate) reference signal to the computer. When the computer grounds this signal, the alternator will stop charging, as in the case of the battery being fully charged and vehicle load demand is low. If this wire is shorted to ground, the alternator will not charge.

The computer monitors the ELD and the FR signal and gets a good idea of what the electrical demand is like. Using this information, the computer controls the charging system through the C circuit. It also uses this information to regulate idle speed. By turning off the alternator, the computer reduces the load on the engine, and thus saves fuel and increases power output when needed.

|

Am I understanding this correctly? Would the easiest thing be to ground the C circuit, perhaps through a resistor to keep from frying something? |

|

|

|

10-06-2014, 09:49 AM

10-06-2014, 09:49 AM

|

#10 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

From your description, I'd start by grounding the C wire. Its the easiest thing to do. Its meant to turn the alternator on/off so a logical place to start. You could put a resistor in there to make sure you don't toast anything. You might want to measure current while you're at it to see if you need it or not.

|

|

|

|

|

The Following User Says Thank You to Daox For This Useful Post:

|

|

|