11-18-2020, 02:24 AM

11-18-2020, 02:24 AM

|

#1 (permalink)

|

|

Banned

Join Date: Nov 2017

Location: Australia

Posts: 2,060

Thanks: 107

Thanked 1,608 Times in 1,137 Posts

|

Multi-channel high speed pressure measurement

Evolution Measurement in the UK have decided to lend me one of their Evoscann professional 16-channel pressure scanners. This is the same unit currently being used in F1 and by major car manufacturers. (8 channel model shown here)

It can sample at up to 1000Hz and has a resolution of 0.01mbar (0.004 inches of water).

They are also lending me their CANbus to USB converter (the Evoscann outputs CAN data). This comes with laptop software allowing logging and display.

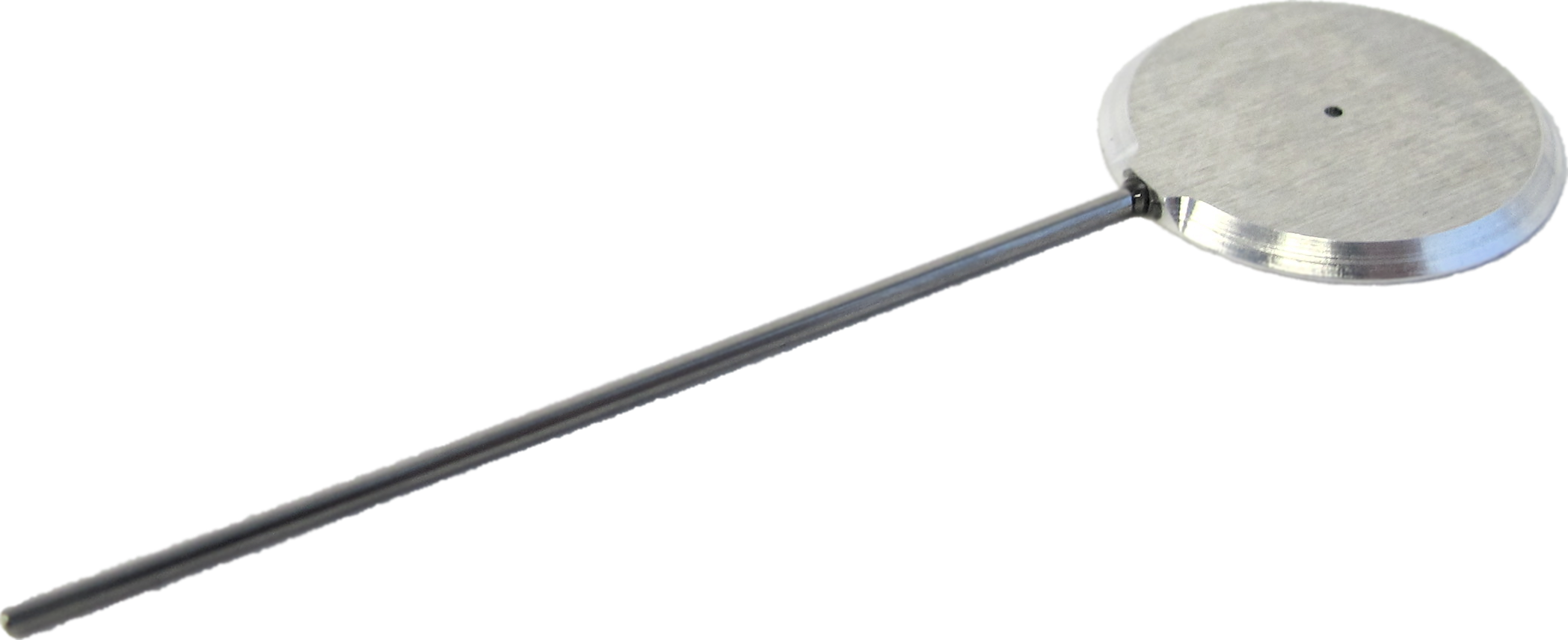

I have bought 16 Scanivalve pressure pucks (thanks to Vman455 for helping source these)....

... and 20 metres of 0.8 x 1.9mm silicon hose.

The huge advantage over using a single puck and gauge is that:

1) 16 pucks can be recorded at once.

2) The readings can be logged at high speed.

So for example I expect to be able to simultaneously measure centreline pressures all along the top and bottom surfaces of the car. I can then make a single change (eg adding a rear spoiler) and see the effect on pressures everywhere.

The high speed logging would, I hope, be able to see oscillatory aerodynamic behaviour (for those with my book, see pages 180 -181) and maybe the action of shedding vortices.

I'd also expect wake pressures to be able to be measured in a way I've not been able to before.

None of the gear (apart from the silicon tube) has yet arrived but tracking shows that hopefully it is not far away.

This gear is worth mega-bucks so it's a unique opportunity. If people have any specific testing that they'd like to see performed, please let me know.

Last edited by JulianEdgar; 11-18-2020 at 02:33 AM..

|

|

|

|

|

The Following 8 Users Say Thank You to JulianEdgar For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-20-2020, 02:49 AM

11-20-2020, 02:49 AM

|

#2 (permalink)

|

|

Banned

Join Date: Nov 2017

Location: Australia

Posts: 2,060

Thanks: 107

Thanked 1,608 Times in 1,137 Posts

|

Electronics from the UK are due Monday, according to tracking.

I've ordered another 20 metres of 0.9mm silicone tube - I suddenly realised that with 16 sensors, the first 20 metres wasn't going to go very far.

The pressure pucks have, according to tracking, now departed Tokyo, Japan (on their way from Champaign, Illinois.)

I am thinking of doing lots of measurement on our W212 Mercedes diesel sedan - fairly low drag, no modifications. Could easily add mock-up spoiler, undertrays, separation edges, etc.

(Not our car but it looks like this):

|

|

|

|

11-20-2020, 07:11 AM

11-20-2020, 07:11 AM

|

#3 (permalink)

|

|

Mechanical engineer

Join Date: Jan 2009

Location: Kitee (Finland)

Posts: 1,277

Thanks: 273

Thanked 846 Times in 418 Posts

|

I would like to see adjustable kambback being tested.

-For that you will need 5mm thick abs sheet which is about 300mm wide and about 1500mm long this you can measure from the car. That you attach with duck tape to roof edge. Rear edge you could bend to about 60 degree to meet the rear edge of the vehicle vertically or attach a metal bracket. 3mm abs migth also be sturdy enough, but I quess 5mm is safer bet

- on the rear edge of the trunk you make 90 degree angle bracket where you have sliding slots where you can adjust the angle. Based on internet side pictures you will need about 150mm adjustment in heigth

- Sides you need to block with clear pvs contruction plastic etc

- Then the measuring pots on the center line of that abs and also to to the vertical side of the tail.

- It should automatically form tapering spline shape which is optimal and wanted.

With this you can see and show what kind of roofline rear shape brings the lowest drag if I have understood correctly how those pressure sensors could be used. I am mainly interested to see if your claims on the "template" are proven false. Construction itself is really easy to make and does not necessary require any drilling to body if test speeds are kept reasonable. That is what I would test if I had that kind of change available.

What do you think?

|

|

|

|

11-20-2020, 11:39 AM

11-20-2020, 11:39 AM

|

#4 (permalink)

|

|

Banned

Join Date: Nov 2017

Location: Australia

Posts: 2,060

Thanks: 107

Thanked 1,608 Times in 1,137 Posts

|

Quote:

Originally Posted by Vekke

I would like to see adjustable kambback being tested.

-For that you will need 5mm thick abs sheet which is about 300mm wide and about 1500mm long this you can measure from the car. That you attach with duck tape to roof edge. Rear edge you could bend to about 60 degree to meet the rear edge of the vehicle vertically or attach a metal bracket. 3mm abs migth also be sturdy enough, but I quess 5mm is safer bet

- on the rear edge of the trunk you make 90 degree angle bracket where you have sliding slots where you can adjust the angle. Based on internet side pictures you will need about 150mm adjustment in heigth

- Sides you need to block with clear pvs contruction plastic etc

- Then the measuring pots on the center line of that abs and also to to the vertical side of the tail.

- It should automatically form tapering spline shape which is optimal and wanted.

With this you can see and show what kind of roofline rear shape brings the lowest drag if I have understood correctly how those pressure sensors could be used. I am mainly interested to see if your claims on the "template" are proven false. Construction itself is really easy to make and does not necessary require any drilling to body if test speeds are kept reasonable. That is what I would test if I had that kind of change available.

What do you think?

|

You can easily do that test for yourself - no pressure testing needed. Just measure changes in total drag using the throttle stop technique. |

|

|

|

11-20-2020, 10:06 PM

11-20-2020, 10:06 PM

|

#5 (permalink)

|

|

Moderator

Join Date: Feb 2012

Location: Urbana, IL

Posts: 1,940

Thanks: 199

Thanked 1,807 Times in 943 Posts

|

I was about to say the same--not sure what you could glean from pressure-testing that device which you couldn't ascertain more easily and immediately by simply measuring drag.

Tests I would be interested in seeing:

-base pressure variation, on both Insight and Mercedes--is it uniform or variable based on location? Does the base pressure fluctuate with time or is it steady?

-pressure change on the Mercedes' roof with a spoiler (after seeing what happened on a fastback, I'm curious what a notchback does)

-pressure change under the Mercedes with a spoiler

-pressure change on the boot lid and backlight with vortex generators along the roof edge (I don't think I've ever seen this measured aside from the Mitsubishi paper and they didn't show data without their wing)

I'm sure I'll think of more, but that's off the top of my head.

|

|

|

|

11-20-2020, 10:39 PM

11-20-2020, 10:39 PM

|

#6 (permalink)

|

|

Banned

Join Date: Nov 2017

Location: Australia

Posts: 2,060

Thanks: 107

Thanked 1,608 Times in 1,137 Posts

|

Base pressure variation, on both Insight and Mercedes--is it uniform or variable based on location? Does the base pressure fluctuate with time or is it steady?

Yes, I thought I'd use an array of all 16 sensors in the base area and log at the highest speed I can. My expectation is that (a) the pressures will vary depending on location, and (b) they will be quite unsteady as vortices are shed.

Pressure change on the Mercedes' roof with a spoiler (after seeing what happened on a fastback, I'm curious what a notchback does)

Pressure change under the Mercedes with a spoiler

I thought I use all 16 sensors along the car centreline top and bottom and trial various mods, including a rear spoiler, front air dam and full undertray.

Pressure change on the boot lid and backlight with vortex generators along the roof edge (I don't think I've ever seen this measured aside from the Mitsubishi paper and they didn't show data without their wing)

Great idea. I'd also tuft test the Mercedes - something I've not done with this car.

|

|

|

|

11-21-2020, 07:53 AM

11-21-2020, 07:53 AM

|

#7 (permalink)

|

|

EcoModding Lurker

Join Date: Feb 2020

Location: North carolina

Posts: 45

Thanks: 6

Thanked 45 Times in 24 Posts

|

Quote:

Originally Posted by JulianEdgar

This gear is worth mega-bucks so it's a unique opportunity. If people have any specific testing that they'd like to see performed, please let me know.

|

Quote:

Originally Posted by JulianEdgar

You can easily do that test for yourself - no pressure testing needed. Just measure changes in total drag using the throttle stop technique.

|

Wow, how nice of you to ask others for specific testing ideas and then tell them to go test it themselves(note sarcasm). Throttle stop testing doesn't work on vehicles with drive by wire and a cvt transmission which makes that method of testing useless on the most plentiful hybrid sold in the world. |

|

|

|

11-21-2020, 09:06 AM

11-21-2020, 09:06 AM

|

#8 (permalink)

|

|

マット

Join Date: Nov 2015

Location: Indiana

Posts: 718

Thanks: 131

Thanked 258 Times in 188 Posts

|

Quote:

Originally Posted by Yippeekyaa

Wow, how nice of you to ask others for specific testing ideas and then tell them to go test it themselves(note sarcasm). Throttle stop testing doesn't work on vehicles with drive by wire and a cvt transmission which makes that method of testing useless on the most plentiful hybrid sold in the world.

|

To find the change in drag that the template add-on would make using the pressure change would require him to

Quote:

|

Originally Posted by Road Vehicle Aerodynamics, AJ Scibor-Rylski, pg 15

Integration of the pressure around the circumference (he is referring to a cylindrical example for calculating drag based on pressures)will produce an aerodynamic force which in this case would be simply the drag of the cylinder.

|

My summary: 1. Plot the pressure over the entire car. Then 2. integrate that data to see the change in drag. Then repeat those 2 steps with the modified version.

So it would be infinitely easier to just do throttle stop testing, which is probably why he suggested it.

It doesn't look like either of them have a prius so I'm not sure why you projected that onto their interaction. You are correct though and can only suggest you try something similar to Vmans test (I bolded the part I was referring to).

Quote:

Originally Posted by Vman455

-I did test the air curtain ducts, both with coast downs and fuel economy over a section of road. The first version of the front ducts increased drag about a third as much as rolling all the windows down, but adding the rear ducts to it reduced drag so that there was no change from no ducts at all. The front ducts also noticeably and negatively impacted stability--the front end felt "squirrelly" in crosswinds, passing truck wakes, etc.

Coast down tests with the front ducts on and off (with rear ducts on for both) were inconclusive--there was just too much variability to measure a small effect. So I went out on a calm night on US 45 and measured fuel economy over a 3-mile section north and south, 6 runs in each configuration. Front ducts alone showed 0.29% decrease in fuel economy at 55 mph (70.1 mpg average base/69.9 mpg front ducts), but adding the rear ducts showed 1.28% improvement in fuel economy over no ducts at all (70.1 mpg base/71.0 mpg front and rear ducts); it appears the efficiency improvement is attributable to the rear ducts or some synergistic effect between rear and front. Further, the car is extremely stable with the new front ducts, which is reason enough to keep them on.

|

I don't have a prius either so I don't have any first hand suggestions.

__________________

1973 Fiat 124 Special

1975 Honda Civic CVCC 4spd

1981 Kawasaki KZ750E

1981 Kawasaki KZ650 CSR

1983 Kawasaki KZ1100-A3

1986 Nissan 300zx Turbo 5 spd

1995 Chevy Astro RWD (current project)

1995 Mercury Tracer

2017 Kawasaki VersysX 300

2022 Corolla Hatchback 6MT

https://www.youtube.com/channel/UC6s...LulDUQ8HMj5VKA

https://www.youtube.com/channel/UC6s...LulDUQ8HMj5VKA

|

|

|

|

11-21-2020, 04:20 PM

11-21-2020, 04:20 PM

|

#9 (permalink)

|

|

Banned

Join Date: Nov 2017

Location: Australia

Posts: 2,060

Thanks: 107

Thanked 1,608 Times in 1,137 Posts

|

Quote:

Originally Posted by M_a_t_t

To find the change in drag that the template add-on would make using the pressure change would require him to

My summary: 1. Plot the pressure over the entire car. Then 2. integrate that data to see the change in drag. Then repeat those 2 steps with the modified version.

So it would be infinitely easier to just do throttle stop testing, which is probably why he suggested it.

|

Even worse than that!

To find the change in drag that the template add-on would make using the pressure change would require

1. Plotting the pressures over the entire car in very fine detail (ie hundreds of readings)

2. Working out the horizontal resultant forces for each measurement

3. Integrating with respect to area

Far easier and more accurate to just measure total drag. Given that Vekke just wanted to prove/disprove a shape, simply pick a car where this is easiest done - ie one with a mechanical throttle. There's only a few billion to choose from! |

|

|

|

11-25-2020, 02:43 AM

11-25-2020, 02:43 AM

|

#10 (permalink)

|

|

Banned

Join Date: Nov 2017

Location: Australia

Posts: 2,060

Thanks: 107

Thanked 1,608 Times in 1,137 Posts

|

Pressure measuring system has arrived, as have the 16 pressure measuring pucks. Should be able to do some initial testing in a few days.

|

|

|

|

|