03-31-2014, 08:56 PM

03-31-2014, 08:56 PM

|

#6371 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

It's not fair to you! I was just saying that because it's an interesting story. I was wondering what that $35 was. From Jerald Dodson, Paypal... Hey! Someone just bought $35 worth of something from me, but I have no idea what it was. And Man, that name sounds so familiar! I don't sell anything that costs $35. haha. That was very generous, and I appreciate it.

On a separate note, there was a big snake (big compared to a garter snake) in my yard today, and I shot him right in the head with a bb gun. Now I'm trying to identify the body.. I don't know what kind it is, but I figured it would try to eat my children. So, I was all paranoid opening my shop to do the milling. Thinking a 40 foot python/rattler hybrid was going to jump out at me.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

03-31-2014, 11:33 PM

03-31-2014, 11:33 PM

|

#6372 (permalink)

|

|

EcoModding Apprentice

Join Date: Oct 2010

Location: southland NZ

Posts: 153

Thanks: 38

Thanked 86 Times in 55 Posts

|

Quote:

Originally Posted by MPaulHolmes

Not a problem. In your case, you could probably adjust the PI loop values (Kp and Ki). Or, you could adjust the throttle settings. Instead of 8 & 0, try

t-pos-gain 20

t-pwm-gain 12

save

The lowest possible current ramp rate on your controller is already like 2000 amps/second or something, so I think the problem is somewhere else.

|

Hi Paul

Its in the car and working so I'm just going to enjoy the lovely autumn weather

I'll think about fixing it later

I haven't got any actual numbers about its ramp time, it just feels like its getting into its stride at about 50Kph

I wonder if the advanced brush timing is doing it - so the current is constant but I get more torque as the revs increase ....  |

|

|

|

|

The Following User Says Thank You to duncan For This Useful Post:

|

|

04-01-2014, 11:15 AM

04-01-2014, 11:15 AM

|

#6373 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Some pictures...

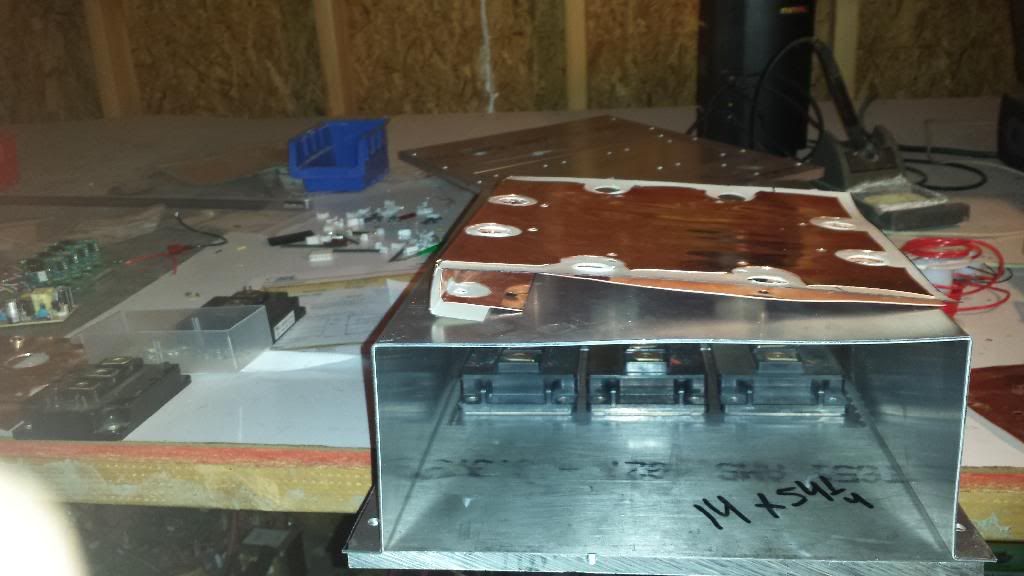

Base Plate, with area milled flat where the IGBTs will go:

3 600v 600amp IGBTs:

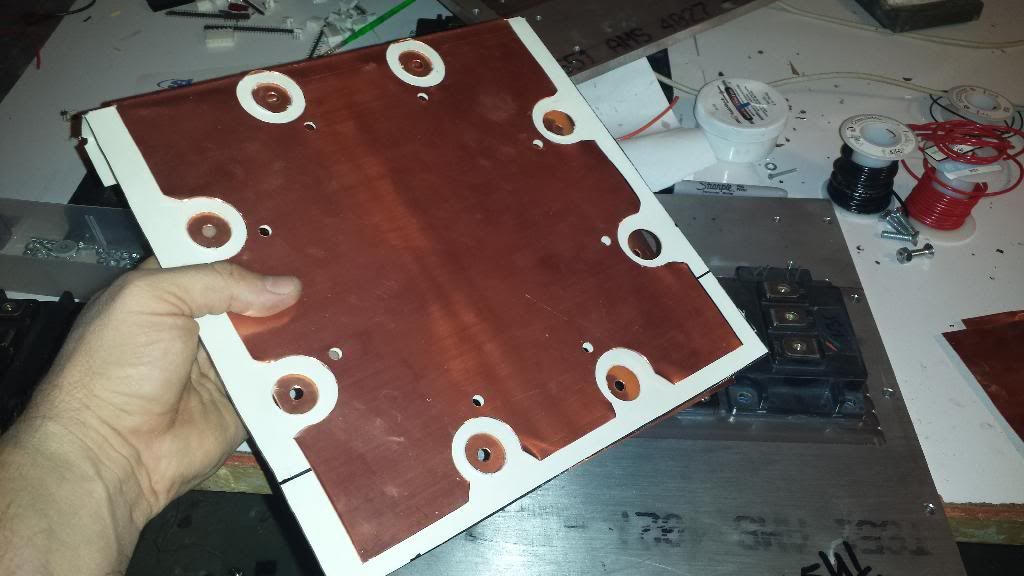

copper, nomex, copper sammich. hmm hmm good: haha

With enclosure. Enclosure is around 4.3" tall. The 3 capacitors aren't here yet, so I can't mount that:

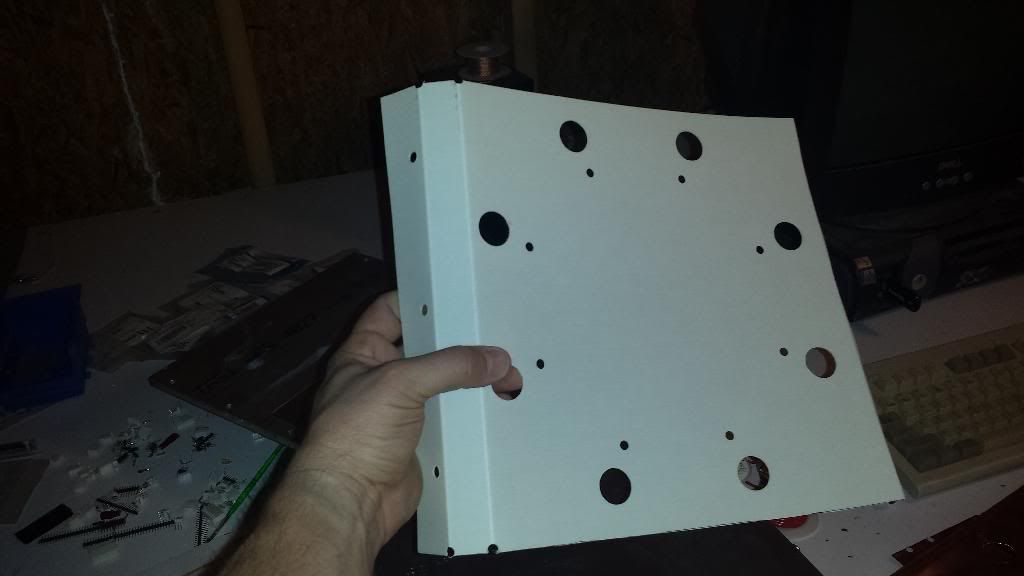

Nomex, all by itself. 20 mil is considered safe to 800v. The hole pattern is symmetric, so I could mill the top 3/4 of the holes (all my mill could fit), and then flip it, and mill the bottom holes that had been missed:

And it's cheap too! Here's where I got it. That works out to like $4 per controller for the isolation material:

https://shop.eis-inc.com/sap(bD1lbiZ...nbr=NMX4102001

Last edited by MPaulHolmes; 04-01-2014 at 11:23 AM..

|

|

|

|

|

The Following User Says Thank You to MPaulHolmes For This Useful Post:

|

|

04-01-2014, 11:29 AM

04-01-2014, 11:29 AM

|

#6374 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

By the way, I'm planning on running it at 8KHz PWM, which is audible. If it turns out to be a problem, I'll have to go with software PWM, and spread spectrum switching. It's just that the IGBTs are so big, that they really can't switch all that fast. But if you have software PWM, then you can have the pwm frequency spread over a range of values: 7.800 kHz, 7.801kHz, ... 8.200kHz, etc.. At this point I don't know how much the frequency has to vary for it to be effective.

|

|

|

|

04-01-2014, 02:06 PM

04-01-2014, 02:06 PM

|

#6375 (permalink)

|

|

PLUGnGO

Join Date: Sep 2012

Location: Olympia Wa

Posts: 137

Thanks: 75

Thanked 82 Times in 54 Posts

|

Quote:

Originally Posted by MPaulHolmes

By the way, I'm planning on running it at 8KHz PWM, which is audible. If it turns out to be a problem, I'll have to go with software PWM, and spread spectrum switching. It's just that the IGBTs are so big, that they really can't switch all that fast. But if you have software PWM, then you can have the pwm frequency spread over a range of values: 7.800 kHz, 7.801kHz, ... 8.200kHz, etc.. At this point I don't know how much the frequency has to vary for it to be effective.

|

Hmmm I'm a little worried, a continuous 8000Hz is one piercing tone:

Square Waveform | Online Audio Wave File Generator

I guess we will have to wait and see how it actually sounds. |

|

|

|

04-01-2014, 02:15 PM

04-01-2014, 02:15 PM

|

#6376 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

The nice thing is, we can choose any frequency from 0 to like 16kHz (without spread spectrum switching), but 16KHz would probably produce too much heat under high power situations. Damien could probably comment on how the 8KHz sounds when it's in the engine compartment. I think he uses 8KHz with his IGBTs. I just downloaded 10KHz, and that seemed significantly "quieter". It's all just a trade off. Higher switching frequency = more heat. There's really no downside to spread spectrum switching, other than the annoyance of a little extra time of writing code for software PWM. Maybe I should do that. Oh heck, let's try it all!

|

|

|

|

04-01-2014, 02:29 PM

04-01-2014, 02:29 PM

|

#6377 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

The boards will be delayed a few days, I'm just now finding because of Tomb Sweeping day in China. I looked it up. A guy cut a hunk of his leg meat off for his lord to eat. Then the lord got in charge again, but forgot about the leg meat guy, so he looked for him, found him in a mountain, set the mountain on fire to smoke him out I guess, which killed him. The end. LOL.

|

|

|

|

04-01-2014, 02:35 PM

04-01-2014, 02:35 PM

|

#6378 (permalink)

|

|

PLUGnGO

Join Date: Sep 2012

Location: Olympia Wa

Posts: 137

Thanks: 75

Thanked 82 Times in 54 Posts

|

Quote:

Originally Posted by MPaulHolmes

The nice thing is, we can choose any frequency from 0 to like 16kHz (without spread spectrum switching), but 16KHz would probably produce too much heat under high power situations. Damien could probably comment on how the 8KHz sounds when it's in the engine compartment. I think he uses 8KHz with his IGBTs. I just downloaded 10KHz, and that seemed significantly "quieter". It's all just a trade off. Higher switching frequency = more heat. There's really no downside to spread spectrum switching, other than the annoyance of a little extra time of writing code for software PWM. Maybe I should do that. Oh heck, let's try it all!

|

Okay looks like there are some options, I thought from your earlier post that 8K hz as high as the ights could go.

Speaking of heat. I was looking at mounting the controller in my truck. Easiest option is to mount on 3/4" spacers above a board with a fan recessed in the board. The fan would blow air through the 3/4" gap between the bottom of the controller and the board. Do you think that will work or is a heatsink going to be needed? |

|

|

|

04-01-2014, 02:40 PM

04-01-2014, 02:40 PM

|

#6379 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Nah, 8kHz just seems to be the favorite for high performance controllers. The Soliton1 uses 8KHz under high power situations I think. It's a smoothly varying tradeoff from 0Hz to like 50KHz. At 50KHz, it's a molten fireball of waste heat. At very low frequency, the poor capacitor can't handle the huge current ripple, and it ends up just taking everything from the batteries, and you have no control of current.

|

|

|

|

04-01-2014, 03:26 PM

04-01-2014, 03:26 PM

|

#6380 (permalink)

|

|

PLUGnGO

Join Date: Sep 2012

Location: Olympia Wa

Posts: 137

Thanks: 75

Thanked 82 Times in 54 Posts

|

Quote:

Originally Posted by MPaulHolmes

Nah, 8kHz just seems to be the favorite for high performance controllers. The Soliton1 uses 8KHz under high power situations I think. It's a smoothly varying tradeoff from 0Hz to like 50KHz. At 50KHz, it's a molten fireball of waste heat. At very low frequency, the poor capacitor can't handle the huge current ripple, and it ends up just taking everything from the batteries, and you have no control of current.

|

I see a need for some kind of dash mounted temperature gauge. Either something that reads the data stream or an off the shelf remote thermometer attached to the base plate.

|

|

|

|

|