03-04-2016, 07:33 PM

03-04-2016, 07:33 PM

|

#41 (permalink)

|

|

(:

Join Date: Jan 2008

Location: up north

Posts: 12,762

Thanks: 1,585

Thanked 3,556 Times in 2,218 Posts

|

I read they're so hard to get the solar racers can scarcely get 'em. :/

I want a set of the tubeless Michelins Pac Car II used- Crr .001.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

03-05-2016, 02:07 AM

03-05-2016, 02:07 AM

|

#42 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,098

Thanks: 8,259

Thanked 9,021 Times in 7,454 Posts

|

Quote:

|

Those sound like very short, weak swing arms to me. If you had another set, about one wheel radius above the first, you might have reasonable A-arms. Bamboo or wood, plywood would not have an efficient arrangement of fibers to take the stress.

|

I'm thinking of a rectangular sheet with triangular cutouts to give a diamond-shaped chassis with arms that reach to the center on the sides. The plywood is available in vertical grain, the way it's used in balsa/fiberglass composites; and with choices of 1/4, 1/2 or 3/4" thickness the width might be 2-6". Wrapped in fiberglass? |

|

|

|

03-05-2016, 02:25 AM

03-05-2016, 02:25 AM

|

#43 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2008

Location: N. Saskatchewan, CA

Posts: 1,805

Thanks: 91

Thanked 460 Times in 328 Posts

|

Quote:

Originally Posted by freebeard

I'm thinking of a rectangular sheet with triangular cutouts to give a diamond-shaped chassis with arms that reach to the center on the sides. The plywood is available in vertical grain, the way it's used in balsa/fiberglass composites; and with choices of 1/4, 1/2 or 3/4" thickness the width might be 2-6". Wrapped in fiberglass?

|

Wood makes a good core for fiberglass springs, so if you add strategically oriented unidirectional tapes, you get a lot more great possibilities. However, anything resembling a swing axle usually has a very high roll center and produces bad scrub on bumps. |

|

|

|

03-05-2016, 01:54 PM

03-05-2016, 01:54 PM

|

#44 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,437

Thanks: 24,483

Thanked 7,412 Times in 4,802 Posts

|

mirrors and plan-taper

*Didn't know if you could deepen your side mirror housings.

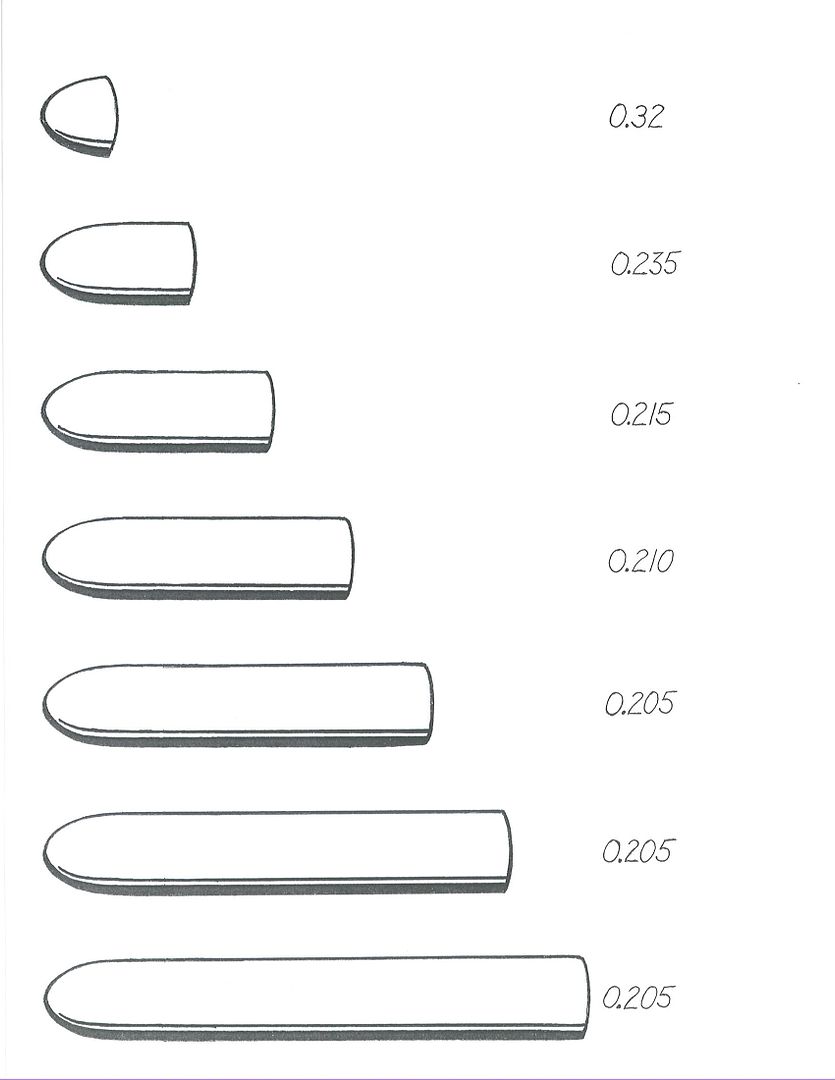

*Also,in plan-taper,'Kamm' discovered that adding body side camber reduced drag even if it added 10% to frontal area

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following 3 Users Say Thank You to aerohead For This Useful Post:

|

|

03-05-2016, 07:23 PM

03-05-2016, 07:23 PM

|

#45 (permalink)

|

|

EcoModding Lurker

Join Date: Feb 2016

Location: Cornwall, UK

Posts: 18

Thanks: 5

Thanked 11 Times in 7 Posts

|

Im having the front wheels running 10 degree negative camber and the rear at 7 degrees camber and I wouldn't find it safe at all if I started to modify the tyres especially if they are spinning around at 40mph on a odd camber. I would like find some Michelin tyres for sure.

This is another picture of side of the car but with the components and my body. See how little room I have around my body and that picture doesn't include my arms or the steering handlebar.

I really can't raise the cockpit opening up too much as you can see, maybe only 10mm or so. I might put a lip around the front of the opening but I'm trying to use the airflow that goes into the cockpit more effectively which is why I got the two drainage channels as mentioned earlier in the thread as well as some cooling ducts which will be behind the shoulders that will help keep the motor at a reasonable temperature. Adding the lip will try throw the air over but they will mostly increase the size of the rear wake and have a bigger low pressure area in the cockpit.

As for the A arms or any suspension, it will be difficult to keep the steering geometry and linkages all correct with the camber, caster, kingpin angle, scrub radius etc to ensure that the tyres doesn't wear quickly and have good, stable steering.

Plus any travel in the wheels will mean a bigger bodywork so the wheels will only be solidly mounted to the chassis.

The flex in the chassis will only be in between the front wheels and the back wheels. In order to keep the ground clearance as high as possible, the material that I will be sitting on will be quite thin and the rest of the chassis will be thicker to carry the load. The aerodynamics is a major part of the car's performance and will take first priority on how I will be making the car, most likely will be laminated sheet material and whatever flex there is in the end, I will take. Most of the cars out there including my previous ones have a quite stiff chassis anyway to make sure the driver is well protected in either a head on or a T-bone crash.

Yeah you can have fairings for the mirror, for the previous cars I didn't have the time to make some mirror fairings out of foam or 3D printed or vacuum formed, but will try for this car. Some teams has cheekily put the mirrors inside the cockpit, which basically renders them useless but does remove them from the airflow. I prefer to put them on the top as I like to see what cars are coming up behind despite the aero penalty although I would like to be driving off in the distance  |

|

|

|

|

The Following User Says Thank You to stealth For This Useful Post:

|

|

03-06-2016, 03:35 AM

03-06-2016, 03:35 AM

|

#46 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2008

Location: N. Saskatchewan, CA

Posts: 1,805

Thanks: 91

Thanked 460 Times in 328 Posts

|

With such a shallow cockpit, you should probably wear a skinsuit to reduce drag from any internal flow feeding the cockpit opening, and the circulation within it. I can't imagine that the camber is doing you any good at all. I know that it is difficult to maintain perfect wheel alignment with suspension, but most vehicle designers consider that mastery to be essential. A flexible frame at least eliminates loose pivots. As with most things, suspension just takes more planning to reap the benefits. You are already dealing with the toe-in setting. It is used to make sure that whatever flex is there can never produce toe-out, even under braking, which is very unstable. Fortunately, pneumatic tires easily develop "slip angles" with little friction. Jobs like tire construction require a new skill set, followed by testing, but obviously they can be done. The best racing bike tires are still handmade. You'll just have to grow in the areas that look most promising to you. Let us know how it goes?

|

|

|

|

03-06-2016, 03:53 AM

03-06-2016, 03:53 AM

|

#47 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,098

Thanks: 8,259

Thanked 9,021 Times in 7,454 Posts

|

So—*solid axle for the low roll center and quarter-elliptic springs?

Are the handlebars under your thighs, like a recumbent bike?

If the rear view mirror was on your helmet, it could be smaller for the same field of view.

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

03-08-2016, 05:49 PM

03-08-2016, 05:49 PM

|

#48 (permalink)

|

|

EcoModding Lurker

Join Date: Feb 2016

Location: Cornwall, UK

Posts: 18

Thanks: 5

Thanked 11 Times in 7 Posts

|

The camber is not for any steering or grip purposes, it only helps to reduce the frontal area significantly since a cambered wheel would take less space when in full lock than a noncambered wheel in full lock when both have the same wheel track. Two of the fastest cars in the last few years have significant amount of camber so it's a proven way of improving the aerodynamics.

The steering handlebar will be above my legs, in my last car, I had each handlebar on each side of my body and because it was very tight in that car, my hands were getting numb after a while, so will try something different this time.

Will let you all know how it goes, probably will post some build photos here, when I hopefully start building it in May.

|

|

|

|

|

The Following 2 Users Say Thank You to stealth For This Useful Post:

|

|

03-08-2016, 06:06 PM

03-08-2016, 06:06 PM

|

#49 (permalink)

|

|

EcoModding Lurker

Join Date: Nov 2008

Location: Bristol, UK

Posts: 22

Thanks: 0

Thanked 4 Times in 2 Posts

|

Quote:

Originally Posted by stealth

Joe of Loath - I always have wondered what's it like to drive one of those, I raced closely against one with same design but in carbon fibre at the final of 2013 and it looked good, is it slightly more unstable in the corners or does it not matter too much? Also did you ever use or experiment with derailleur gearing?

|

Which one, the F24+ or the F24 with the outrigger?

The F24+ car handled great, it had single wishbone front suspension with rubber engine mounts as dampers, barely 2cm of travel but enough so that when you steered into a corner the body roll would increase the camber and lower the centre of gravity. At Goodwood and Castle Coombe I never had to brake, just lift off for the chicanes. Picture: https://lh3.googleusercontent.com/-u...2/IMG_1809.JPG

The F24 car handled OK, it understeered and scrubbed tyres but that may have been due to the ackermann of the recumbent trike hubs we were using. It was never unstable due to being so damn wide!

We used derailleur gearing on our previous car, but it was too complicated for the younger, less experienced drivers. You need to have a hawk eye on your power consumption and shift up and down according, and the younger drivers would forget and power round the track as fast as possible, sucking all the juice from the batteries. The F24 cars remained single speed after the first couple of years - even for the national podiums. With good driver training they tend not to slow down so much, so gears aren't as vital. We had a rubber bump clutch type mechanism to stop us from snapping chains.

The F24+ car had a 9 speed transmission I believe, and with the two of us more experienced drivers racing we could drive it to suit pretty much any power budget. That was actually the inspiration for my final university project (an automatic transmission for bicycles) but that's a story for another day.

EDIT: I see some roll bar and camber talk. Our roll bar was faired with pieces of wooden edging strip (basically a dowel cut in half) and pieces of 1mm aluminium bent and taped into place around the square box section. It gives you a great aerodynamic cross section with virtually zero weight penalty. Eventually though we built a full fairing, with the (perhaps fanciful) idea that any wind other than a headwind would give us some forwards momentum.

RE camber, back in the early days (~2004 ish) lots of cars had problems with wheels folding in corners. Because bicycle wheels work best with a vertical load, camber helps to keep the load vertical (in relation to the wheel hub) through corners. It also reduces tyre deflection.

FWIW we used Schwalbe Marathons in 16" on all our cars.

__________________

Last edited by Joe of Loath; 03-08-2016 at 06:17 PM..

|

|

|

|

|

The Following User Says Thank You to Joe of Loath For This Useful Post:

|

|

03-08-2016, 06:36 PM

03-08-2016, 06:36 PM

|

#50 (permalink)

|

|

EcoModding Apprentice

Join Date: May 2008

Location: N. Saskatchewan, CA

Posts: 1,805

Thanks: 91

Thanked 460 Times in 328 Posts

|

Quote:

Originally Posted by stealth

The camber is not for any steering or grip purposes, it only helps to reduce the frontal area significantly since a cambered wheel would take less space when in full lock than a noncambered wheel in full lock when both have the same wheel track. Two of the fastest cars in the last few years have significant amount of camber so it's a proven way of improving the aerodynamics.

|

If you think that's a proof, you are going to be floundering for a long time. There are better ways to get away with unsuitable wheels than by increasing rolling resistance.

|

|

|

|

|