07-19-2009, 03:38 AM

07-19-2009, 03:38 AM

|

#21 (permalink)

|

|

EcoModding Lurker

Join Date: Mar 2009

Location: Britol, UK

Posts: 11

Thanks: 0

Thanked 0 Times in 0 Posts

|

A sweet project. I can't wait to see it finished!

Nikki.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

07-22-2009, 02:26 PM

07-22-2009, 02:26 PM

|

#22 (permalink)

|

|

Master EcoModder

Join Date: Apr 2009

Location: Charlton MA, USA

Posts: 463

Thanks: 31

Thanked 183 Times in 94 Posts

|

Alright, another weekend past, and alot more work to show. The Engine Is Out! it was a large feat of Sunday due to the fact that the engine hoist was bent due to a mishap with moving a 2200lb machine. But we took a big hammer and beat it back into shape for the lift. It took us about 2 hours to remove the engine with the transmission attached. We had forgotten to undo 2 small power steering lines and some weird cable that connects the transmission to the steering column!? We still dont know what it was for. The engine and transmission we guess weigh about 800 lbs. It was very heavy. All cast iron 327 block and heads.

I have been looking into batteries over the past week and a half and we are almost certain that we will be using some form of lithium! Not sure which yet, but it will most likely be 45 of the Sky Energy 120Ah cells at the minimum. Maybe 180 or 200 Ah cells depending on how much else goes into the car.

So here are the few time lapse videos of the deconstruction nights. I was able to get 2 angles for the pulling of the engine.

Putting the car on jack stands and removing exhaust:

Removing the engine:

And:

So hopefully over the next week or so I can finish removing the AC components and the rest of little unnecessary thing along with the rest of the steering linkage to prepare for the Rack and Pinion conversion.

Pictures:

Well Enjoy.

-Adam

P.S. I got a few surprises for later on in the week.

Last edited by adamj12b; 07-22-2009 at 02:40 PM..

|

|

|

|

07-22-2009, 03:07 PM

07-22-2009, 03:07 PM

|

#23 (permalink)

|

|

Wannabe greenie

Join Date: Aug 2008

Location: Yorba Linda, CA

Posts: 1,098

Thanks: 5

Thanked 53 Times in 40 Posts

|

Excellent. Love the time-lapse video.

From this site: http://www.35pickup.com/mulligan/weight.txt

It appears that the small block Chevy from the 60's and 70's weighs around 575 pounds, and your battery pack would only be about 445 pounds. So add in the motor, controller and racks, subtract the exhaust, gas tank (18 gallons of gas weigh about 110 pounds!), accessories and other ICE components, and you're probably talking only a couple hundred pounds over stock. That's going to be a killer car. |

|

|

|

07-22-2009, 06:19 PM

07-22-2009, 06:19 PM

|

#24 (permalink)

|

|

Master EcoModder

Join Date: Apr 2009

Location: Charlton MA, USA

Posts: 463

Thanks: 31

Thanked 183 Times in 94 Posts

|

Clev,

Dot forget I am removing the THM-400 automatic transmission that weighs 134 lbs without torque converter and fluid.

This will be replaced with a T10 transmission. I actually have 2 T10's, 1-3 speed and 1-4 speed. The 3 speed is almost brand new with only a few thousand miles on it. The 4 speed is unknown condition and will be gone through and parts replaced if needed. What do you guys think we should use? 3 Speed or 4 Speed? We also have 2 sets of rear end gears for the car, We believe 4.11's and 3.36's. The 4 speed weighs about 70lbs dry. Thats about half the weight of the THM400.

Were very happy that we will be less then the weight of the car with all the electronic components. We hope to balance the car for optimal weight distribution.

-Adam

|

|

|

|

07-22-2009, 06:31 PM

07-22-2009, 06:31 PM

|

#25 (permalink)

|

|

Wannabe greenie

Join Date: Aug 2008

Location: Yorba Linda, CA

Posts: 1,098

Thanks: 5

Thanked 53 Times in 40 Posts

|

Quote:

Originally Posted by adamj12b

Clev,

Dot forget I am removing the THM-400 automatic transmission that weighs 134 lbs without torque converter and fluid.

This will be replaced with a T10 transmission. I actually have 2 T10's, 1-3 speed and 1-4 speed. The 3 speed is almost brand new with only a few thousand miles on it. The 4 speed is unknown condition and will be gone through and parts replaced if needed. The 4 speed weighs about 70lbs dry. Thats about half the weight of the THM400.

|

Cool, even better.

Most EV's use just a couple of gears, so if you can get a good combo of ratios in a 3-speed, I'd use it and save having that fourth unused gear spinning around. Plus, a newer unit will probably have better bearings that will waste less electricity. |

|

|

|

07-23-2009, 08:02 AM

07-23-2009, 08:02 AM

|

#26 (permalink)

|

|

Master EcoModder

Join Date: Apr 2009

Location: Charlton MA, USA

Posts: 463

Thanks: 31

Thanked 183 Times in 94 Posts

|

More Good News!

I finally figured out what the transmission is that we have. I went out to the garage last night and got the numbers off of the castings and started searching the internet. This morning I had some replays on some forums and some links to identification sites. Basically what it comes down to is we have a Muncie M20! Basically for you who done know what this is, It is a very rugged transmission.

-Adam

|

|

|

|

07-25-2009, 08:54 AM

07-25-2009, 08:54 AM

|

#27 (permalink)

|

|

Master EcoModder

Join Date: Apr 2009

Location: Charlton MA, USA

Posts: 463

Thanks: 31

Thanked 183 Times in 94 Posts

|

Ok, A few questions and some updates. We have decided that we will be using the Sky Energy cells. Not sure the size yet, they will be the 120's at the least.

My question is, Will the Warp 11 be enough motor to make the corvette go at least 100 Mph?? Its not something that will happen too often, but its a requirement of the project.

What I could figure, And please correct me if I'm wrong, is the spec sheet says the motor produces 43HP at 72V and 453A. So that would be 32,616 W. The battery pack we are using will be 162V charged so figuring with no sag at the same amperage, ( 162V x 453A ) the motor should be outputting 73,386 W. Thats 2.25 times the output power or 96.75 HP. Is this correct? That should be continuous output power correct? Do you think this is enough power to make the car do what we want?

So we were able to get some more little work done this week. We removed the gas tank and the rest of the AC system. Last night we took out the whole dash to be able to work on the wiring and heating system. The car is looking really EMPTY!

I have also been working on a program that will run on a 7.1" touchscreen monitor in the center dash. This program will control and monitor the entire car(Gauges, BMS, Motor Controller, Charger, and System Settings). There will be no physical gauges in the car, only virtual ones. The program will interface with the BMS system that I am working on, to display all charge and discharge information, as well as individual cells to find weak ones before they become problems. The controller section will be displaying all controller information such as temps and currents and voltages. The charger section will display charger information suck as charge times and estimated charge time left and things like charge cost. Lastly on the list is the settings page. This will hold all the system settings as well as settings for the charger, controller and BMS. It will be able to export a backup of settings incase something happens as well.

All the graphics have been designed from scratch by my friend Kyle. It is a very sharp looking system.

Here are 2 pictures, 1 of the Home Screen and 1 of the Overview Screen.

-Adam

|

|

|

|

07-26-2009, 06:38 PM

07-26-2009, 06:38 PM

|

#28 (permalink)

|

|

Master EcoModder

Join Date: Apr 2009

Location: Charlton MA, USA

Posts: 463

Thanks: 31

Thanked 183 Times in 94 Posts

|

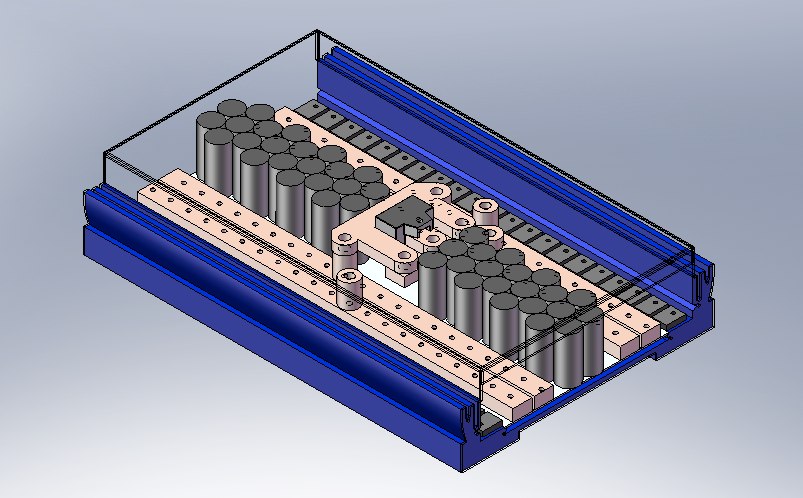

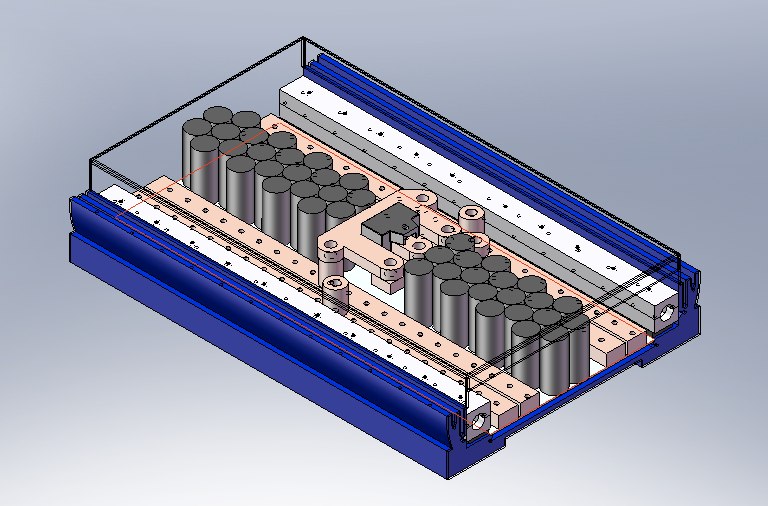

So here is the other thing I have been working on. I have been working on a version of Paul & Sabrina's Open Source Motor Controller capable of very high power output. I started with a the heat sink from a car stereo amplifier. I then designed a power board that fit in the heat-sink. The power stage board holds 21 Mosfet/Diode pairs. I have upgraded the diodes from the 60A STTH6002CW 's to 90A APT30S20BCTG 's. The capicators have been upgraded to 820uF from the 470's. There is 42 capacitors. Totaling 34,440uF. The controller should be capable of about 1680A continuously, With the pairs capable of 6720A for 8.3ms. At 165V that is 1.108 Mega watts of power. The continuous power is about 303kW of power. The controller will have the option of being water cooled if I need it. If it can stay cool by just the air moving over it, I will not using the water cooling, Saving weight.

I plan on using this controller at 162V, driving a Warp 11.

I have not tested the mosfet/diode pairs yet at 162V to see if they will hole up, but I have some parts on the way so testing can begin.

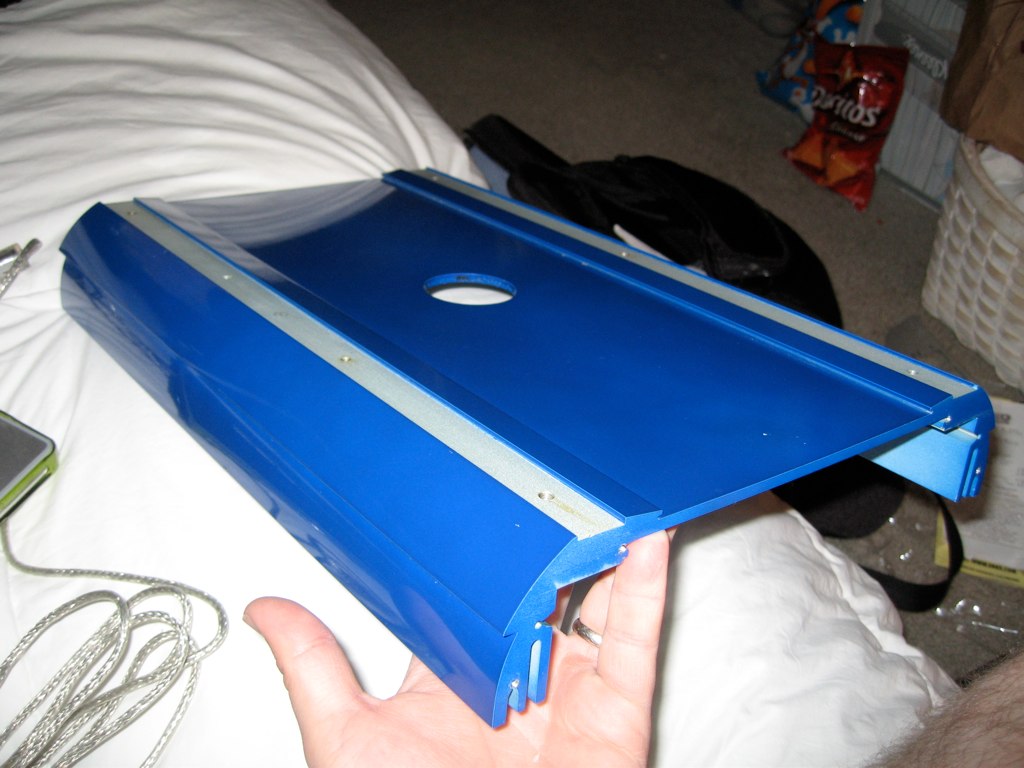

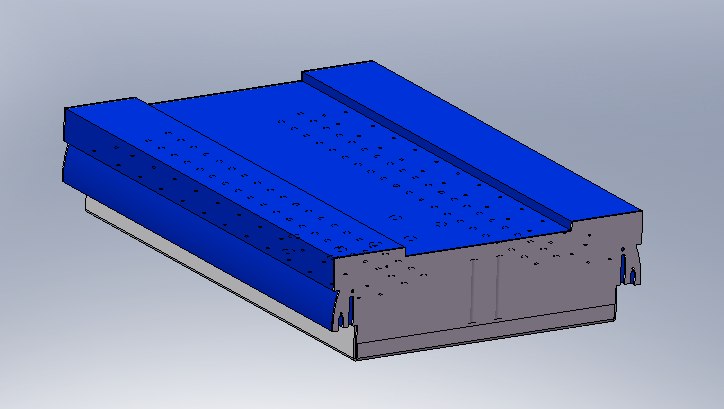

So here are some pics of the heat-sink and some renderings of the completed controller.

Heat Sink:

Renderings:

No Water Blocks:

With Water Blocks:

-Adam |

|

|

|

07-30-2009, 06:36 PM

07-30-2009, 06:36 PM

|

#29 (permalink)

|

|

EcoModding Lurker

Join Date: Jul 2009

Location: netherlands europe

Posts: 16

Thanks: 0

Thanked 0 Times in 0 Posts

|

this looks like a verry interesting project the corvette should be a good car for the conversion its sleek low resistance and kindah light im keeping my eye on this one .

i was wondering about those controllers and how they work is it a solid state version of a row of relays raising the power in stages ?

trying to see how its build i seen some drawings that look loke its the same scematic multiplied a couple of times

|

|

|

|

07-30-2009, 06:51 PM

07-30-2009, 06:51 PM

|

#30 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Wow, that is a heck of a lot of power!

|

|

|

|

|