10-06-2014, 10:52 PM

10-06-2014, 10:52 PM

|

#621 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,418

Thanks: 8,367

Thanked 9,125 Times in 7,534 Posts

|

Couldn't you build a flatbed for less? 2ea 4x10 pieces of Plymetal swingdoor material would be maybe $240. Plus some wooden joists.

My friend built his eggshaped camper back in the 70s. It appeared [apparently] on page 92 of Shelter (Shelter Publications ISBN 0-394-70991-8). That page was torn out of my copy.

He started with plywood ribs with diagonal wire bracing, laid on 1x2 stringers and then shingled the whole thing with hand tapered shingles. The foam was sprayed on from the inside. It looked great and he lived in it for a number of years. It still looked good after being perched on a hillside, abandoned for years.

I'd suggest fish-scale shingles, laid horizontally.

The closest thing I can find is this:

...only backwards.

|

|

|

|

|

The Following 2 Users Say Thank You to freebeard For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

10-08-2014, 05:44 PM

10-08-2014, 05:44 PM

|

#622 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,534

Thanks: 24,520

Thanked 7,436 Times in 4,817 Posts

|

flatbed for less

I'm kind of a scaredy cat. Since it's still a work truck I kinda like the idea of an all-steel bed,just in case the 'worst' happened.

The steel would wad up but it would absorb a lot of energy and would probably remain in one piece,containing the load.

A neighbor out here was rear-ended once,sending his work tools through the air.A few of them tried to go through him.

If I start from a Toyota bed,it will bolt right on,I'll have a tough floor,front bulkhead,integrated side posts,steel tailgate frame,and steel gate.

And if the new bed has no flexure,it will help protect the composite bedcover from deformation during chassis twist.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

10-08-2014, 08:07 PM

10-08-2014, 08:07 PM

|

#623 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,418

Thanks: 8,367

Thanked 9,125 Times in 7,534 Posts

|

Fair enough. Get a utility bed and apply Mair to the lockers behind the wheelwell?

|

|

|

|

10-10-2014, 04:40 PM

10-10-2014, 04:40 PM

|

#624 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,534

Thanks: 24,520

Thanked 7,436 Times in 4,817 Posts

|

wheelwells

Quote:

Originally Posted by freebeard

Fair enough. Get a utility bed and apply Mair to the lockers behind the wheelwell?

|

*I might be able to begin the plan-taper 'within' the span of the wheelhouse,maybe even a little before.Even if I had to do some sort of blister to accommodate the top,rear of the tires.

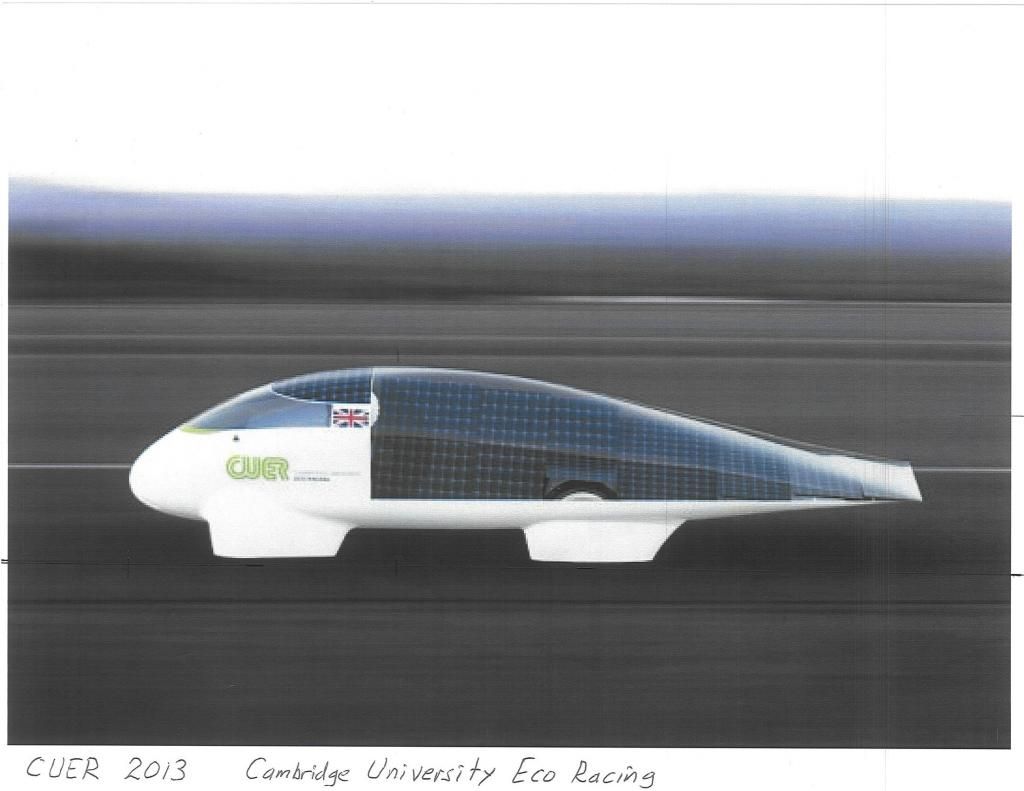

*At least I could be achieving the 40-degrees of tumblehome which allows the boat-tailing to really sing,achieving the smaller transom at a much shorter length than in possible now.Like the Cambridge University CUER of last year

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

10-10-2014, 06:24 PM

10-10-2014, 06:24 PM

|

#625 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,418

Thanks: 8,367

Thanked 9,125 Times in 7,534 Posts

|

Tumblehome through the length of the wheelwell, then plan taper after? The line between the flat side and the aeroformed part would be along a line from the axle centerline and the top rear of the roof.

|

|

|

|

10-11-2014, 12:45 PM

10-11-2014, 12:45 PM

|

#626 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,534

Thanks: 24,520

Thanked 7,436 Times in 4,817 Posts

|

through the length

Quote:

Originally Posted by freebeard

Tumblehome through the length of the wheelwell, then plan taper after? The line between the flat side and the aeroformed part would be along a line from the axle centerline and the top rear of the roof.

|

I'd try for plan taper within the span of the wheelhouse as well as the tumblehome.

If the tire 'erupted' out of the surface,a blister could be formed over the eruption,tapering away and to the rear,forming a node which could contain marker/ tail lamps,which when viewed from behind,indicated to following traffic,the full width of the truck.

To 'skip' the blisters would require a more narrow rear axle or perhaps different wheel offsets.Not sure that the wheel bearings would like the latter.I've never fully loaded the truck,it might not be that big a deal.She's was at 4,236-lbs for the trip,with a GVWR of 5,000-lbs.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

10-11-2014, 03:02 PM

10-11-2014, 03:02 PM

|

#627 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,418

Thanks: 8,367

Thanked 9,125 Times in 7,534 Posts

|

Skegs?

|

|

|

|

|

The Following 2 Users Say Thank You to freebeard For This Useful Post:

|

|

10-11-2014, 03:56 PM

10-11-2014, 03:56 PM

|

#628 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,534

Thanks: 24,520

Thanked 7,436 Times in 4,817 Posts

|

skegs?

Why not?

I don't think they'd upset the flow too much.

If they had illumination,everyone would know that the vehicle up ahead is wider than it seems in the dark.

They could be resin-surfaced foam which would disintegrate if a pedestrian got too close.

Visually interesting.

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

10-12-2014, 12:42 AM

10-12-2014, 12:42 AM

|

#629 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,418

Thanks: 8,367

Thanked 9,125 Times in 7,534 Posts

|

The bubble-top '62 Starlight coupe was always one of my favorites.

Most rear diverters have downward facing out endcaps. Imagine that Olds' bumper replaced by a logrithmic curve that start about the front of the wheelwell. Pretty flat past the axle, then brought up to 10-22°. With four or five fences like a Lotus.

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

08-02-2015, 10:09 PM

08-02-2015, 10:09 PM

|

#630 (permalink)

|

|

Master EcoModder

Join Date: Dec 2008

Location: Southern WI

Posts: 829

Thanks: 101

Thanked 563 Times in 191 Posts

|

Optimum Length/Width Ratio For Minimum Drag

Hi Phil,

I'm not trying to be picky, even though it could come across this way, but I do see some conflicting length/width ratios for the minimum airfoil shape posted at EcoModder.

The link below has some information that I will present below, and discuss.

http://ecomodder.com/forum/showthrea...rt-c-9287.html

The image below has sections of several minimum drag sources that show length/width ratios.

Starting from the top of the graphic, the minimum L/W ratio seems to be 2.5:1. I did not scale the graphic closely.

The second graphic shows a ratio of 1.0/.255 = 3.92 L/W

The third graphic clearly shows 2.5 L/W ratio

The C-version Streamlining Template shows a ratio of 4.72/2 = 2.36

I've looked on-line and did not find any other L/W information for subsonic winglets, and minimum drag, so this type of information may be limited to Hucho and other rare sources.

I do recall that you have mentioned that the minimum drag occurs at a L/W ratio of 2.5 many time before, yet some of the other sources do not match this, including the Streamlining Template.

Thanks, Jim.

Last edited by 3-Wheeler; 08-02-2015 at 10:19 PM..

|

|

|

|

|

The Following User Says Thank You to 3-Wheeler For This Useful Post:

|

|

|