02-05-2015, 11:29 AM

02-05-2015, 11:29 AM

|

#141 (permalink)

|

|

Master EcoModder

Join Date: Dec 2007

Location: Southern California

Posts: 1,490

Camryaro - '92 Toyota Camry LE V6 90 day: 31.12 mpg (US) Red - '00 Honda Insight Prius - '05 Toyota Prius 3 - '18 Tesla Model 3 90 day: 152.47 mpg (US)

Thanks: 349

Thanked 122 Times in 80 Posts

|

Quote:

Originally Posted by pgfpro

For Cold EGR on my engine there are a few advantages I have found.

1) Knock Reduction.

I have found that when Cold EGR is enable I can maintain high load and decrease the air to fuel ratio (add fuel) and lower BSFC from increasing the timing advance while maintaining high load. A traditional HOT EGR would increase a tendency to knock and timing advance would have to be decreased.

OK now this is where it gets confusing. With my ability to run Ultra Lean Burn I have to increase timing advance a ton to make any power due to lean burn's slow burn rate. This helps a ton with pumping losses (running at 0 inch/hg to 2 psi). But there's a point of diminishing returns. Running this lean reduces pumping losses a ton, but at the same time increases BSFC due to a poorer efficiency due to running a higher timing advance. So by running mass amounts of cold EGR to keep from knocking I can now increase the fuel amounts for a more efficient BSFC with out losing high load due to less mass air. Where before if I were to add fuel the engine would increase its power due to the large amounts of air from the lean condition. This would in turn make me have to back off the throttle in which would increase pumping losses.

|

According to this article, it's not the timing advance that hurt per say, but the very low load.

http://www.swri.org/3pubs/ttoday/Sum...n-and-Cool.pdf

At low loads, you're essentially losing a bunch of heat, and that's what hurts efficiency. When you add cooled EGR, you reduce the peak combustion temperatures, which reduces the amount of heat you're loosing to the block/coolant. You should also be able to increase the amount of advance on cooled EGR to help a little bit with efficiency. Another benefit of cooled EGR, and turbocharging in general, is recycling heat, which helps with efficiency in general.

|

|

|

|

|

The Following User Says Thank You to roflwaffle For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

02-05-2015, 09:16 PM

02-05-2015, 09:16 PM

|

#142 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,573

Thanks: 1,350

Thanked 628 Times in 408 Posts

|

Quote:

Originally Posted by roflwaffle

According to this article, it's not the timing advance that hurt per say, but the very low load.

http://www.swri.org/3pubs/ttoday/Sum...n-and-Cool.pdf

At low loads, you're essentially losing a bunch of heat, and that's what hurts efficiency. When you add cooled EGR, you reduce the peak combustion temperatures, which reduces the amount of heat you're loosing to the block/coolant. You should also be able to increase the amount of advance on cooled EGR to help a little bit with efficiency. Another benefit of cooled EGR, and turbocharging in general, is recycling heat, which helps with efficiency in general. |

I think I'm understanding you correctly? The article you posted is pretty much

what I'm seeing also. I'm referring to high load-ultra lean burn only in my above post on cold EGR.

Going by my Close Cycle Interactive Otto Cycle simulator, I get these numbers.

30.5 A/F = 2500K = .432kJ Wnet per cylinder per cycle

22.6 A/F = 3000K = .557kJ Wnet per cylinder per cycle

14.4 A/F = 4200K = .859kJ Wnet per cylinder per cycle

All three are at 100 kPa MAP and 333K IAT.

Now there is whole other topic of what the true air pressure is after the intake valve closes.  But as a example you can see above what Wnet out is, verse the different A/F ratios, and on my setup going from 14.4 A/F to 30.5 A/F really takes a hit in energy/heat?

Anyway I really appreciate the post roflwaffle. I wish more people on here would comment on this crazy project of mine. I would love to discuss this with everyone on here.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

Last edited by pgfpro; 02-05-2015 at 11:32 PM..

|

|

|

|

02-06-2015, 03:45 PM

02-06-2015, 03:45 PM

|

#143 (permalink)

|

|

Master EcoModder

Join Date: Dec 2007

Location: Southern California

Posts: 1,490

Camryaro - '92 Toyota Camry LE V6 90 day: 31.12 mpg (US) Red - '00 Honda Insight Prius - '05 Toyota Prius 3 - '18 Tesla Model 3 90 day: 152.47 mpg (US)

Thanks: 349

Thanked 122 Times in 80 Posts

|

It's not a problem man! This is something I've been interested in a while, and it's nice to see a shade-tree implementation of it. Practical physics and all that. I'd love to fiddle around with something similar if I had the time.

I'm not sure what your simulation includes, so I can't comment on the specifics, but there's a good general description of lean burn on page 5 of this pdf versus part load on page 2, where negative (pumping) work results from the difference in pressure between the crankcase and expanding cylinder after combustion that didn't take in the amount of fuel/air associated with full load.

http://www.researchgate.net/profile/...90ff65b52b.pdf

In terms of cooled EGR, I'm guessing that the when it's added, the pressure will start higher during compression, and maybe go a bit higher before combustion (1->2), the peak combustion temperature and pressure will be lower, and more work should be extracted from combustion, resulting in a lower 4 value and improved efficiency.

The addition of cooled EGR allows the specific heat of the intake charge to be higher, and the "effective" compression ratio, where "effective" describes how much stuff actually gets stuffed in the cylinder (since we aren't at stoich/normal pressure any more), instead of the volume ratio of expansion to compression, increases too. This allows for two avenues that increase efficiency (The efficiency part of cycle analysis is near the end of this wiki page).

Otto cycle - Wikipedia, the free encyclopedia |

|

|

|

|

The Following 2 Users Say Thank You to roflwaffle For This Useful Post:

|

|

02-07-2015, 05:18 PM

02-07-2015, 05:18 PM

|

#144 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,573

Thanks: 1,350

Thanked 628 Times in 408 Posts

|

Quote:

Originally Posted by roflwaffle

It's not a problem man! This is something I've been interested in a while, and it's nice to see a shade-tree implementation of it. Practical physics and all that. I'd love to fiddle around with something similar if I had the time.

I'm not sure what your simulation includes, so I can't comment on the specifics, but there's a good general description of lean burn on page 5 of this pdf versus part load on page 2, where negative (pumping) work results from the difference in pressure between the crankcase and expanding cylinder after combustion that didn't take in the amount of fuel/air associated with full load.

http://www.researchgate.net/profile/...90ff65b52b.pdf

In terms of cooled EGR, I'm guessing that the when it's added, the pressure will start higher during compression, and maybe go a bit higher before combustion (1->2), the peak combustion temperature and pressure will be lower, and more work should be extracted from combustion, resulting in a lower 4 value and improved efficiency.

The addition of cooled EGR allows the specific heat of the intake charge to be higher, and the "effective" compression ratio, where "effective" describes how much stuff actually gets stuffed in the cylinder (since we aren't at stoich/normal pressure any more), instead of the volume ratio of expansion to compression, increases too. This allows for two avenues that increase efficiency (The efficiency part of cycle analysis is near the end of this wiki page).

Otto cycle - Wikipedia, the free encyclopedia |

Thanks for the links, awesome information and formulas!!!

The simulator I'm using now besides my two spread sheets I made form different books is the thermofluids.net TEST calcs and Interactive's.

As much as I love math I really don't love it that much. lol So these interactives and spread sheets make it much faster to look at different scenarios.

One thing I want to take a good long look at is crank case pressure. Its on my "to do list"

Anyway thanks again rotfwaffle for your input and interest

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

02-07-2015, 09:30 PM

02-07-2015, 09:30 PM

|

#145 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,573

Thanks: 1,350

Thanked 628 Times in 408 Posts

|

Update Turbo Box Version 4.0

OK well I changed the design again. I have three holes in the floor pan.

1st one is the exhaust pipe that feeds the low pressure turbo's turbine.

2nd one is low-pressure turbo charge pipe compressor out let back to the high pressure turbo inlet.

3rd one is low pressure turbine outlet to exhaust pipe.

My thoughts are two scoops one on the 1st and 2nd one, beige color in pic. Both of these are on the flat floor board. So high pressure area?

The 3rd one is on the 45 degree part of the floor that attaches the lower floor to the upper trunk floor. I'm thinking that this will have a low pressure area (detached air flow) and will now be my exit of air flow in the turbo box???

Thoughts????????

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

02-07-2015, 10:23 PM

02-07-2015, 10:23 PM

|

#146 (permalink)

|

|

Growin a stash

Join Date: Jun 2014

Location: Austin TX

Posts: 820

Thanks: 418

Thanked 311 Times in 234 Posts

|

Let me summarize at a high level- you are filling your car with turbos!

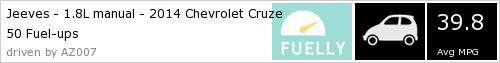

I'm not knowledgeable enough to leave a serious comment, but it looks like you've made some big changes (judging by the fuel log). When I originally saw this thread, I thought you were way in over your head and it would be one of those projects that never gets finished.

I still would love to see what it looks like under the hood!

__________________

2024 Chevy Bolt

Previous:

2015 Nissan Leaf S, 164 mpge

|

|

|

|

|

The Following User Says Thank You to ME_Andy For This Useful Post:

|

|

02-08-2015, 01:40 PM

02-08-2015, 01:40 PM

|

#147 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,573

Thanks: 1,350

Thanked 628 Times in 408 Posts

|

Quote:

Originally Posted by ME_Andy

Let me summarize at a high level- you are filling your car with turbos!

I'm not knowledgeable enough to leave a serious comment, but it looks like you've made some big changes (judging by the fuel log). When I originally saw this thread, I thought you were way in over your head and it would be one of those projects that never gets finished.

I still would love to see what it looks like under the hood!

|

Here's what it looks like today. I have the radiator pulled out to get access to the manifold for my new version 2.0 heat coil for the hot air system.

In this picture you can see the high pressure turbo inlet has a 90* elbow silicone coupler that goes down and to the rear of the car to connect to the low pressure turbo's compressor outlet.

Other then that it doesn't look to different then stock.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

02-09-2015, 10:28 PM

02-09-2015, 10:28 PM

|

#148 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,573

Thanks: 1,350

Thanked 628 Times in 408 Posts

|

Here's a pic with description of what's what.

Also the charge pipe from the high pressure turbo to the intercooler will be replaced by a one piece aluminum unit. This is still in test phase, with just a bunch of parts I have laying around.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

Last edited by pgfpro; 02-10-2015 at 01:24 AM..

|

|

|

|

|

The Following User Says Thank You to pgfpro For This Useful Post:

|

|

02-14-2015, 05:10 PM

02-14-2015, 05:10 PM

|

#149 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,573

Thanks: 1,350

Thanked 628 Times in 408 Posts

|

Finishing up my low pressure turbo inlet tube to out side of the turbo box.

It's going to be a tube inside of a tube. This will keep a seal from air inside of the box getting to the turbo inlet. The turbo will have to pull air from my quarter vents.

My second proto type waste fuel system is now complete and ready for testing.

I'm more excited about this then my lean burn system. Can't wait to test it

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

02-15-2015, 12:37 AM

02-15-2015, 12:37 AM

|

#150 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,573

Thanks: 1,350

Thanked 628 Times in 408 Posts

|

I'm also considering doing some testing this year at WOT "low boost setting" at 14psi while running lean burn around 22:1 A/F. I've been messing around with my new engine simulator thanks Professor S. Bhattacharjee of San Diego State University.  and have found some very interesting area's that could be tested?

My goals are to use the extra positive air pressure for cooling instead of extra fuel for thermal management. I also will be injecting my "waste solvent" Toluene based as a secondary fuel source for knock suppression.

SI engines with intake manifold injection achieve the lowest fuel consumption at constant engine output dependent on the engine at 20-50% air surplus (lambda = 1.2 - 1.5)" Bosch Automotive Handbook, 8th Edition Page 559.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

|