05-20-2015, 12:04 PM

05-20-2015, 12:04 PM

|

#221 (permalink)

|

|

Master EcoModder

Join Date: Jul 2012

Location: camden, MI

Posts: 324

MC SBX - '95 Chevrolet Monte Carlo LS Last 3: 29.75 mpg (US)

Thanks: 7

Thanked 56 Times in 46 Posts

|

could do something neat like airbags that inflate/deflate based on vehicle speed to get the car lower at high speeds and jack it up at lower ones? I seem to remember that getting used quite a bit in the 90s by OEMs.

__________________

|

|

|

|

|

The Following User Says Thank You to RobertISaar For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

05-20-2015, 11:51 PM

05-20-2015, 11:51 PM

|

#222 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,572

Thanks: 1,343

Thanked 623 Times in 405 Posts

|

This weekend I'm going to start on my second version of my single intake opening valve system with solid lifters. I built a very simple system that holds four of the intake lifters in place with no rocker arms on them, this keeps them from popping out under hydraulic oil pressure. So now I have a single intake valve per-cylinder to promote swirl for ultra lean burn operation. This will also help with engine delt p by increasing intake boost pressure from a more restrictive valve area.

The only downside to this is the fact when I want full maximum performance I will have to pull the valve cover and remove the lifter holders, and put the rockers back on. I will also be experimenting with the exhaust valves also.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

|

The Following 2 Users Say Thank You to pgfpro For This Useful Post:

|

|

05-21-2015, 09:22 AM

05-21-2015, 09:22 AM

|

#223 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Hmm, quite interesting. I look forward to hearing how this turns out.

|

|

|

|

|

The Following User Says Thank You to Daox For This Useful Post:

|

|

05-21-2015, 11:32 AM

05-21-2015, 11:32 AM

|

#224 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,572

Thanks: 1,343

Thanked 623 Times in 405 Posts

|

Quote:

Originally Posted by Daox

Hmm, quite interesting. I look forward to hearing how this turns out.

|

Thanks Daox for the interest.

The way I set my engine up now is I have taking around .200 off the bottom of four HLA intake lifters. When you remove around .190 you open up a small hole in the center of the lifter. This will collapse the lifter, but its enough to still maintain some pressure on the rocker to keep it from falling off. The intake valves with this modification still come off their seats by about 20% as normal. The downside its noisy but my Tilton pump drowns out the lifter noise so its not to bad.

This first version was just a pretest to see if swirl would help reach a more efficient combustion. It was definitely a major improvement. Swirl is by far more advantageous then tumble on a pent roof 4 valve head from all the reading I have done on this subject and now have seen i first hand.

What I found on my own experimenting is I now can run less timing for the same power output. This is a sign that BSFC has improved, and the fuel values show it.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

|

The Following User Says Thank You to pgfpro For This Useful Post:

|

|

05-21-2015, 12:03 PM

05-21-2015, 12:03 PM

|

#225 (permalink)

|

|

Master EcoModder

Join Date: Jul 2012

Location: camden, MI

Posts: 324

MC SBX - '95 Chevrolet Monte Carlo LS Last 3: 29.75 mpg (US)

Thanks: 7

Thanked 56 Times in 46 Posts

|

with how much fabrication you've gone through.... you could consider a new intake manifold, one with split intake runners that would allow you to shut off all flow of air to one of two intake valves while under x RPM via throttle plates, then open up the entire air path above x RPM. should have a negligible effect on high RPM power if calculated/designed correctly while giving you at least the same improvement that actually disabling an intake lifter gives.

the only significant complication with this is going to be dependant on how the intake port runs in your head..... if the port is already split in two at the head, that simplifies things quite a bit, if not, then you would need to split them yourself via welding in a small divider, which is tricky.... to say the least.

__________________

|

|

|

|

|

The Following User Says Thank You to RobertISaar For This Useful Post:

|

|

05-21-2015, 01:04 PM

05-21-2015, 01:04 PM

|

#226 (permalink)

|

|

Lean Burn Cruiser!

Join Date: Dec 2012

Location: Johnston County, NC

Posts: 936

Thanks: 840

Thanked 491 Times in 310 Posts

|

Quote:

Originally Posted by pgfpro

This weekend I'm going to start on my second version of my single intake opening valve system with solid lifters. I built a very simple system that holds four of the intake lifters in place with no rocker arms on them, this keeps them from popping out under hydraulic oil pressure. So now I have a single intake valve per-cylinder to promote swirl for ultra lean burn operation. This will also help with engine delt p by increasing intake boost pressure from a more restrictive valve area.

The only downside to this is the fact when I want full maximum performance I will have to pull the valve cover and remove the lifter holders, and put the rockers back on. I will also be experimenting with the exhaust valves also.

|

Quote:

Originally Posted by pgfpro

Thanks Daox for the interest.

The way I set my engine up now is I have taking around .200 off the bottom of four HLA intake lifters. When you remove around .190 you open up a small hole in the center of the lifter. This will collapse the lifter, but its enough to still maintain some pressure on the rocker to keep it from falling off. The intake valves with this modification still come off their seats by about 20% as normal. The downside its noisy but my Tilton pump drowns out the lifter noise so its not to bad.

This first version was just a pretest to see if swirl would help reach a more efficient combustion. It was definitely a major improvement. Swirl is by far more advantageous then tumble on a pent roof 4 valve head from all the reading I have done on this subject and now have seen i first hand.

What I found on my own experimenting is I now can run less timing for the same power output. This is a sign that BSFC has improved, and the fuel values show it.  |

This is too cool Russell! I have been contemplating valve deletes in the Escort. I read up on a thread that EM member Gasoline Fumes started about deleting valves in his Honda Wagon and saw the improvements he had. Like you, I have also read up on the effects of tumble vs. swirl, and swirl wins out hands down.

I have to get extra cams and ground off a lobe (DOHC 16v engine). Direct cam-to-lifter cantact is a more efficient design, but messed me up with this task

Let me know how the exhaust valve deletes go. I do want to do this, but am curious to the effects. Keep up the awesome work, my friend  |

|

|

|

|

The Following User Says Thank You to BabyDiesel For This Useful Post:

|

|

05-21-2015, 01:34 PM

05-21-2015, 01:34 PM

|

#227 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,572

Thanks: 1,343

Thanked 623 Times in 405 Posts

|

Quote:

Originally Posted by RobertISaar

with how much fabrication you've gone through.... you could consider a new intake manifold, one with split intake runners that would allow you to shut off all flow of air to one of two intake valves while under x RPM via throttle plates, then open up the entire air path above x RPM. should have a negligible effect on high RPM power if calculated/designed correctly while giving you at least the same improvement that actually disabling an intake lifter gives.

the only significant complication with this is going to be dependant on how the intake port runs in your head..... if the port is already split in two at the head, that simplifies things quite a bit, if not, then you would need to split them yourself via welding in a small divider, which is tricky.... to say the least.

|

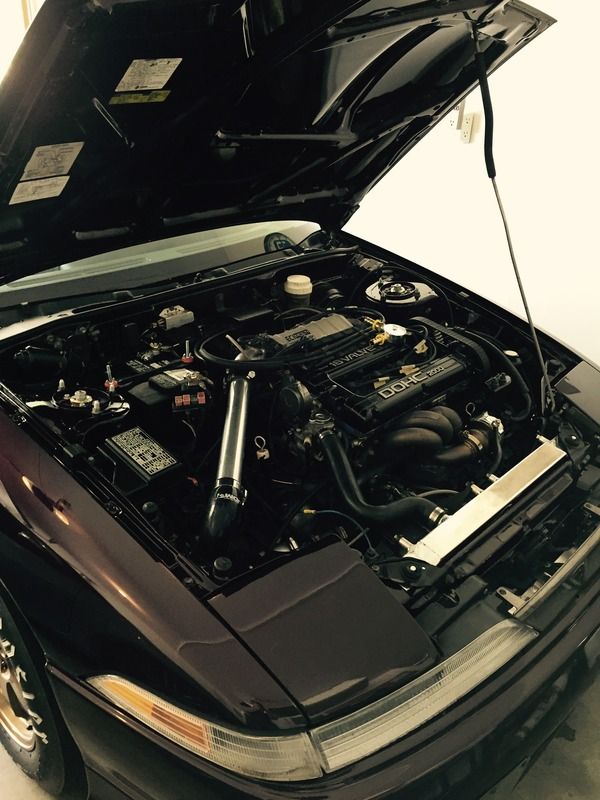

Funny you bring this up.

I'm trying to get my one of these.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

05-21-2015, 11:28 PM

05-21-2015, 11:28 PM

|

#228 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,572

Thanks: 1,343

Thanked 623 Times in 405 Posts

|

My EGR explained.

One of our members had a question on my EGR. He ask how is your high boost killing the EGR Valve???

This is one of my EGR valves I was testing the exhaust pressure signal on.

This is the plate that I will use to block off intake boost pressure to keep it from killing the diaphragm in the EGR. I marked it intake and exhaust. Normally the intake hole is open. You can see by the way the EGR gasket is made.

I'm using a aluminum block off plate that I drilled a small hole into so the exhaust side can flow exhaust and I can get a pressure reading that I will use for data logging back pressure. Some how the 40+ psi is getting past the EGR stem? I didn't even have the hoses attach to the diaphragm and it still kills the diaphragm?

So now I have a copper cooling coil that then turns into a rubber hose that attaches to a boost regulator. I will be manually adjusting the amount of flow the EGR with the regulator.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

|

The Following User Says Thank You to pgfpro For This Useful Post:

|

|

05-25-2015, 12:52 PM

05-25-2015, 12:52 PM

|

#229 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,572

Thanks: 1,343

Thanked 623 Times in 405 Posts

|

Yesterday I was doing some launch testing and ended up braking the top of my radiator hose fitting. So I ordered a new aluminum radiator.

The stock one is dry rotted and you can break it apart with just your fingers???

Well this gives more time to work on the single intake valve system.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

05-30-2015, 06:58 PM

05-30-2015, 06:58 PM

|

#230 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,572

Thanks: 1,343

Thanked 623 Times in 405 Posts

|

Installed the new radiator today. Very happy with the quality and fit and the best part it was only $99.00

Also did some tuning today and now I'm able to run around 15:1 A/F without any knock at 16psi. Back pressure is only 10 psi at this boost level.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

|

The Following 2 Users Say Thank You to pgfpro For This Useful Post:

|

|

|