05-30-2012, 06:27 PM

05-30-2012, 06:27 PM

|

#11 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

Yep, that's pretty much all exactly what I am thinking.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

05-30-2012, 08:08 PM

05-30-2012, 08:08 PM

|

#12 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

Here's some additional food for thought...

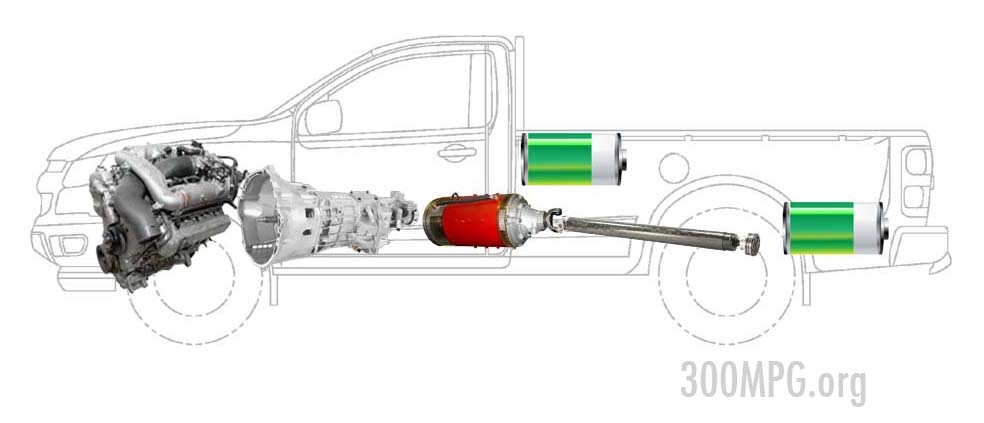

(Components not to scale, location approximate.)

2.4l diesel engine gets connected to 5-speed manual transmission. That will be a little bit of work, as they were never designed for each other.

On the back-end will go a DC, series-wound, forklift motor. It has both a drive-shaft and tailshaft, so it can physically be connected both to the transmission and a shortened drive-shaft (ala EMIS system)

Since it's a manual transmission, I could just put the stick in neutral to leave the diesel disconnected and drive electric only. That also means I would need a reversing contactor and neutral motor timing if I want to back up without the engine. (I would also need to make sure of some way to keep from accidentally making the motor run the diesel BACKWARDS!)

The batteries will most likely have to go in the bed. Since it's a hybrid, the fuel tank and exhaust system are still there under the bed. However, if I don't carry a spare tire, that frees up a bit of space behind the axle for some batteries.

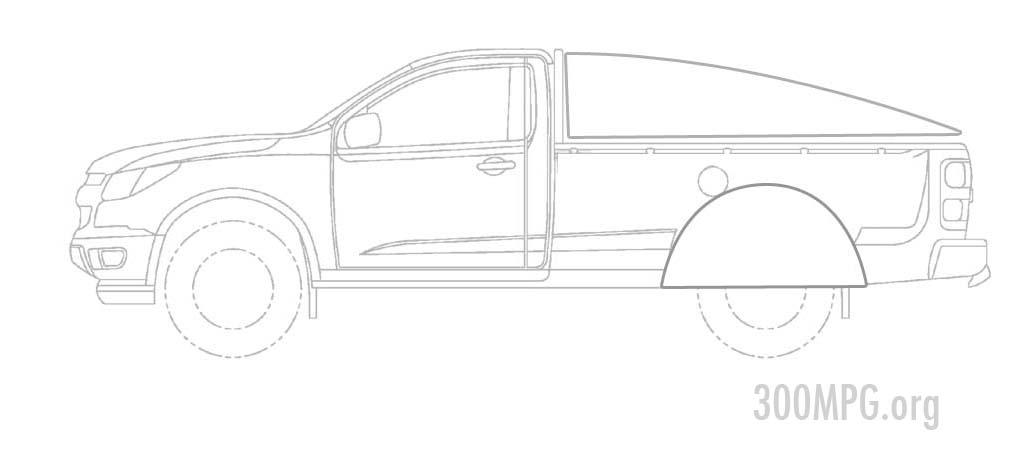

Of course we don't want to forget about aerodynamics either.

That's just a rough drawing, but I think you get the point - trucks have bad aero, so fix it. An aero-cap and rear wheel skirts should help a bit. The truck might also be lowered, and I can experiment with a belly pan as well.

Well, there you have it, my rough idea, more or less.

Ideally, I'd like to run Open Source motor controller, charger, BMS, and maybe instrumention or display. |

|

|

|

05-30-2012, 08:24 PM

05-30-2012, 08:24 PM

|

#13 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

You are right - mounting a motor in line with the drive shaft will be a challenge, but doable for sure. How much torque does your DC motor have? From the pictures it looks massive and should be able to handle direct drive. But I wonder if mounting your motor to the side of the driveline and chain driving a sprocket integrated (welded?) to the transmission output yoke would work.

GOOD

-Simpler

-Further drive ratio reduction

-Easy ratio change

BAD

-Noisy

-Requires maintenance

The ultimate would be using a 4WD/AWD vehicle or a vehicle that was available as one, for example, my wife's Matrix. Install a rear differential from a wreck, driven by a motor. Front drive gasser/rear drive EV/AWD hybrid.

|

|

|

|

05-30-2012, 09:17 PM

05-30-2012, 09:17 PM

|

#14 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

The motor is something like 12" diameter. Should be able to make some pretty good torque.

Two other guys that I know are using the same motor in Ford Ranger EV conversions. Of course that's with the motor going on the transmission in place of the engine, not going onto the driveshaft.

I'm sort of waiting for both those guys to give me some real-world feedback in how well the motors work for them, if they run into any issues, etc.

Physically, the motor is bigger than a Warp 9 and smaller than a Warp 13.

I have a couple photos of the motor at:

http://gallery.me.com/benhdvideoguy#103469

Last edited by bennelson; 05-30-2012 at 09:26 PM..

Reason: getting the motor size right and adding photos

|

|

|

|

05-31-2012, 01:45 AM

05-31-2012, 01:45 AM

|

#15 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

That motor should have more than enough stink for direct drive.

Once you have both the diesel and electric systems working, do you think you will remove the starter and alternator and rely on the electric motor for starting and a DC-DC converter for 12V? The alternator removal would make sense for efficiency in general, but in a home-made project, the redundancy of a starter might not be a bad thing.

|

|

|

|

05-31-2012, 06:50 AM

05-31-2012, 06:50 AM

|

#16 (permalink)

|

|

EcoModding Lurker

Join Date: Feb 2012

Location: Hell

Posts: 28

Thanks: 10

Thanked 6 Times in 6 Posts

|

Starter wouldn't be redundant! When You have to start the diesel (for whatever reason), when the truck is stand still, how will you do that with the DC motor? There is no clutch after the DC motor.

|

|

|

|

05-31-2012, 08:43 AM

05-31-2012, 08:43 AM

|

#17 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

I would want to leave the starter. I wouldn't be able to start the diesel WITHOUT the back wheels turning. I've never bump-started a diesel before. Not sure it works quite as well as a gasser does, with the higher compression, etc.

It would be fun to try though!

|

|

|

|

05-31-2012, 09:55 AM

05-31-2012, 09:55 AM

|

#18 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Diesel engines bump start almost as easy. After the first "difficult" revolution, they actually spin easier than a gas engine because of no throttle plate. You have to see compression as a giant spring. You compress a bigger spring with a diesel, but this spring also pushes back harder to turn the engine on the way back down (on what would be the power stroke if the engine was running).

Quote:

Originally Posted by zsnemeth

Starter wouldn't be redundant! When You have to start the diesel (for whatever reason), when the truck is stand still, how will you do that with the DC motor? There is no clutch after the DC motor.

|

Easy. Put ICE in gear. Step on EV go pedal. EV motor turns driveline, moves truck and rotates ICE (all at the same time) to start ICE.

OR

Step on EV go pedal. Once vehicle is moving, push clutch & put ICE in gear. Dump clutch to start ICE. |

|

|

|

05-31-2012, 10:07 AM

05-31-2012, 10:07 AM

|

#19 (permalink)

|

|

EcoModding Lurker

Join Date: Feb 2012

Location: Hell

Posts: 28

Thanks: 10

Thanked 6 Times in 6 Posts

|

Quote:

Originally Posted by mechman600

Easy. Put ICE in gear. Step on EV go pedal. EV motor turns driveline, moves truck and rotates ICE (all at the same time) to start ICE.

OR

Step on EV go pedal. Once vehicle is moving, push clutch & put ICE in gear. Dump clutch to start ICE.

|

Yeah, looks easy. Especially, when it's in the garage or tight space without runway, as i wrote "if you have to start the diesel for whatever reason".  |

|

|

|

05-31-2012, 10:11 AM

05-31-2012, 10:11 AM

|

#20 (permalink)

|

|

home of the odd vehicles

Join Date: Jun 2008

Location: Somewhere in WI

Posts: 3,892

Thanks: 508

Thanked 868 Times in 654 Posts

|

Quote:

Originally Posted by z_power

First - thanks for starting some very inspiring threads Ben!

DIY and low cost equals to DC these days - it means no regenerative use of motor... So I'd rather consider hybrid-plugin setup, like your DB diesel for high speed cruising and electric for all "unstable dynamics" like acceleration or stop & go traffic.

|

In my mind the point of hybrid is for regen, all is not lost with DC!

You can get regen with DC, you would need a shunt wound motor a few have made series wound do regen with mixed results.

What I wonder, Lee Hart had modded his curtis to do regen but it couldn't handle the amps since it wasn't very controllable, since you have an open source 500amp controller, why not build it to 1000amps and add Lee Harts regen, the stop would not be slow and gentle a good chunk of the time but it would be effective and add some juice back into the battery for the times you need it.

Also I don't think a 1.2 TDI is unobtainium, its just $2500-$6500 to your door which is a lot more than say a $200 5.7/6.2 diesel.

Ah well

|

|

|

|

|