12-04-2012, 01:07 PM

12-04-2012, 01:07 PM

|

#51 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

I doubt that the magnets would be strong enough to hold the cover on while driving with it partly open.

It would just be too easy for wind from the wrong direction and too much leverage.

A while back, I was using a partial plastic tonneau cover that I built from some scrap greenhouse glazing. It worked fairly well, and was designed so that I could just completely remove it if I needed to put something big in the truck.

There was once or twice where I just completely removed it and left it at my parent's house or wherever else I was picking up something big. (Of course if I knew in advance, I simply removed it and left it at home in my garage.)

I liked the simplicity of just completely removing the thing.

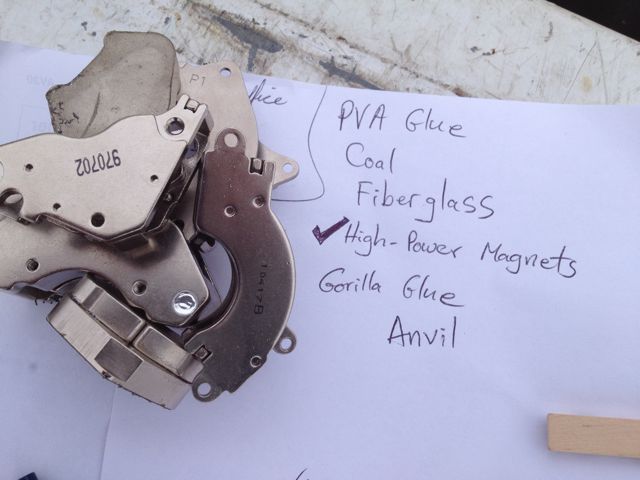

Yesterday, I picked up some hard-drive magnets from my buddy, Tom G. (who you might remember from the AC Dodge Neon project.)

Two of the magnets were "open-face", but the rest were pairs pinned together with spacers that would go around the disk of the hard-drive. It look me a few minutes to figure out how to get them apart without terribly pinching my fingers. What I really needed was a small pry bar that was NOT made of metal. My plastic bicycle "tire irons" worked pretty well to get the magnets apart.

I outlined one of the magnets on a hunk of foam, and then routed out the shape with a small router. (A Dremel Trio - handy tool.)

I had also picked up some Gorilla Glue. I haven't worked with it before, but have heard it's basically like Great Stuff, so that means wearing gloves and being VERY careful where it goes!

I glued in the magnet. The glue did foam up a little more than I planned, but could be easily cut with a razor when it was cured.

After than, I setup a few ounces of fiberglass resin, and put a sample of fiberglass cloth and resin over the top of it. Once that's dried, I SHOULD have a hunk of white foam with a very powerful magnet embedded in it.

I plan to drive around with it stuck to the top of my truck and getting strange looks from people.

Last edited by bennelson; 12-04-2012 at 02:04 PM..

Reason: added photos.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

12-04-2012, 02:05 PM

12-04-2012, 02:05 PM

|

#52 (permalink)

|

|

EcoModding Lurker

Join Date: Jun 2012

Location: Davis

Posts: 8

Thanks: 0

Thanked 3 Times in 2 Posts

|

Quote:

Originally Posted by theycallmeebryan

Beat me to it.

I think it would be easiest and most efficient to have the electric motor drive the front wheels and the diesel drive the rear. That way, the Diesel and transmission can be in there proper configuration, and adding the electric motor where the transfer case would normally be would be a great solution.

That way, you have 3 options. EV Only, EV+Diesel (Assisted towing, acceleration, 4wd, etc), or Diesel Only... almost seemlessly.

I think you may run in to a lot of issues putting the E-motor inline between the transmission and the driveshaft.

|

I'll strongly second that suggestion. If you put the electric motor in-line you will have to have power into it at all times or else you will significantly lower your mileage from the diesel engine turning over the motor as a generator. There's a reason why hybrids use generators and electric drive motors. It's easier to set up an electric switch linkage than a mechanical one.

What I would do is use those two forklift motors. One I would attach to the diesel for use as a generator. The other I would link to the drive shaft. Then it's just batteries and one or two inverters with switching in between. You can run the diesel at optimum RPM that way, and with the right circuitry, start the diesel with the other forklift motor that you are using as a generator. Whether that motor will work optimally as a generator is another question, but it should work alright.

That way, your system efficiency losses are:

A. Heat - nothing you can do about that.

B. Battery charge-recovery losses. That depends on the batteries and their condition.

C. Inverter losses (should be minor) when running power directly from the generator to the drive motor on the highway. But those shouldn't be worse than mechanical transmission losses.

Voila. You have disposed of the entire mechanical transmission build. And you have plenty of good cable to make the wiring harnesses you need. |

|

|

|

12-04-2012, 02:15 PM

12-04-2012, 02:15 PM

|

#53 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

If you spin a series wound motor it doens't generate any power (and thus no drag) until you power the field windings and connect the armature wiring to a load. All you have is bearing and brush drag, and some windage lossses which is all pretty minimal.

|

|

|

|

12-04-2012, 02:32 PM

12-04-2012, 02:32 PM

|

#54 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

While I like the concept of a 4-wheel-drive DIY hybrid, it's going to be more efficient as just two-wheel drive.

There's also a point at which an engine mechanically driving the wheels is more efficient than a serial-hybrid, which is why the Volt DOES have a more where the engine acts as an engine, instead of a generator.

By running the engine to the transmission to the DC Series-Wound motor, it minimizes the driveline the minimum number of components needed for a Hybrid, yet still allows either system to run independent of the other.

Of course, all of this this THEORETICAL. I highly encourage everyone else to build alternate flavors of hybrids, and then we can race them against each other!  |

|

|

|

12-04-2012, 02:53 PM

12-04-2012, 02:53 PM

|

#55 (permalink)

|

|

EcoModding Lurker

Join Date: Jun 2012

Location: Davis

Posts: 8

Thanks: 0

Thanked 3 Times in 2 Posts

|

Quote:

Originally Posted by Daox

If you spin a series wound motor it doens't generate any power (and thus no drag) until you power the field windings and connect the armature wiring to a load. All you have is bearing and brush drag, and some windage lossses which is all pretty minimal.

|

True. You can see what that is pretty easily by putting a wheel or crank on the shaft and spinning it. If it goes easily, drag will be relatively low. |

|

|

|

12-04-2012, 07:06 PM

12-04-2012, 07:06 PM

|

#56 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

I did a little more work on the truck flat cover today.

I started off by trying to clean up the side edges of the cover.

I ran some string from a screw on the front to one on the back, to make a straight line, and then marked it with a black permanent marker.

I used my Ninja Anti-Zombie Scythe (I have no idea what this tool really is, I found it for a dollar at the thrift store, and it's great!) to slice the edge off on an angle in a fairly straight line.

SLICING styrofoam is SO much better than CUTTING because it creates ZERO sawdust. Styrofoam sawdust is so nasty, has horrible static cling, and gets everywhere. But to slice, you need a really sharp blade, and most people don't have foot-long razor blades. This tool comes in pretty close though.

After slicing the edge, I sanded it a bit with a cheap orbital sander hooked up to my shop-vac.

Next, I flipped the cover over and routed out depressions matching the size and shape of the magnets. I misted water into the foam with a spray bottle, squeezed in some Gorilla Glue, and pushed in the magnets. The face of the magnets are flush with the foam, so the magnet will be directly on the metal of the truck bed when the cover is set on top.

The sticky foam glue is curing now. Slowly curing....  |

|

|

|

12-04-2012, 08:15 PM

12-04-2012, 08:15 PM

|

#57 (permalink)

|

|

EcoModding Lurker

Join Date: Aug 2009

Location: Bega, Australia

Posts: 1

Thanks: 0

Thanked 0 Times in 0 Posts

|

... magnets to attach the cover.

... if you need somewhere to get more magnets ...

Old speakers - lots of magnets, and speakers get thrown out all the time.

Also - as a backup, the old-fashioned elasticised cord looping down to some tie-down clips could be added later (if needed).

|

|

|

|

12-04-2012, 10:54 PM

12-04-2012, 10:54 PM

|

#58 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

I got the magnets glued in, and tested it out.

The magnets do indeed seem to stick the lid down fairly well. Since it's just styrofoam, the whole thing does flex quite a bit right now when trying to lift it open.

Once the fiberglass is on, it should stiffen up and be great. Right now, I'm afraid of snapping it in half because of the magnetic pull!

After testing the magnetic adhesion and opening and closing, I closed it all up, and drove to my parent's house, about ten miles away.

At freeway speeds, the cover did not fly off!

I dropped it off over there, so next time I work on it, it can be in heated space. The next step will be doing some fiberglass on the BOTTOM of the cover. So when I screw it up, and it looks back - so what!.

Then, by the time I get to the top/outside, I'll have enough practice that it should look OK.

I'll also have to make some sort of holes on the underside for the prop stick/sticks. Maybe those could double as a spare attachment point for bungie-cords, etc. |

|

|

|

12-04-2012, 11:15 PM

12-04-2012, 11:15 PM

|

#59 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Woohoo Ben. Sounds like things are really coming together good. Looking forward to more.  |

|

|

|

12-05-2012, 01:21 PM

12-05-2012, 01:21 PM

|

#60 (permalink)

|

|

Ecomod noob

Join Date: Feb 2008

Location: Tooele, UT

Posts: 412

ZJ - '95 Jeep Grand Cherokee Laredo Upcountry 90 day: 20.57 mpg (US) Neon - '03 Dodge Neon SE 90 day: 33.46 mpg (US) S'Crew - '02 Ford F150 Supercrew XLT 90 day: 16.4 mpg (US) Ranger - '90 Ford Ranger Last 3: 28.02 mpg (US) Not the Jeep - '03 Dodge Neon SE 90 day: 34.11 mpg (US)

Thanks: 7

Thanked 15 Times in 10 Posts

|

I like this concept. I've been away fro the forum for quite some time but this build has drawn me in. I need to learn a lot more about the DC motor, but my basic questions have been answered so far. I am planning to get a Ford Bronco 2 soon, as I have left over parts from swapping everything out of a 94 Explorer into my son's 90 Ranger. That left me with the 2.3 4 banger and 5 speed. Yes, the Bronco 2 is 4x4, and with the 2.3 I was planning to build it for (hopefully) MPGs. Makes me think I could ditch the transfer case, and mount a motor where the transfer case was. Leaving me a lot of thinking to do for batteries and where to put them. I wasn't planning to build the Bronco 2 as an offroad machine, just a cruiser to beat my F150 and Jeep on MPGs. THis would be fun to use, even add "Hybrid" stickers or badging... Thanks for a great idea!!!

__________________

When it comes to Heroes, RENEGADES are mine!

|

|

|

|

|