12-05-2012, 01:28 PM

12-05-2012, 01:28 PM

|

#61 (permalink)

|

|

Zerg Lurker

Join Date: May 2008

Location: New York City

Posts: 44

Thanks: 5

Thanked 3 Times in 3 Posts

|

Wow, Ben, this is an incredible project, and something I'll rather enjoy following if only as a bystander.

I sadly haven't the time or money - even the minimal of really either - nor the work space to attempt something like this, but it's fun to live vicariously. I'm also planning at some point (perhaps this coming summer?) to make some "factory look" fiberglass eco parts. Grill blocks, rear wheel covers, etc, that can easily be attached and detached, all painted up to match the car to see if I can routinely squeeze a few more MPGs out of my car. Sadly I've never quite seen the mileage I got out of it the first few months I owned it, which oddly, was when I was having trouble driving the stick.

Forgive the fact that n00b questions follow - I'm curious, not knocking on your choices.

Anyway, I wanted to ask a question, or, probably, several in the form of one:

Why is it that you didn't just put the bed to use hosting a genny like your Metro? I'm sure you can find one that would do the trick of charging your batts while still weighing less and consuming less fuel than the diesel, right? From my understanding, the electric motors should be able to provide higher torque and power than the diesel (especially the one in question), especially if you 'teamed' them up somehow.

This would also give the advantage of having more room and weight for batteries, right?

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

12-05-2012, 10:30 PM

12-05-2012, 10:30 PM

|

#62 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

It is possible to add a generator to an electric pickup truck. A friend of mine just threw a generator in the back of his whenever he had a borderline long-distance trip.

The trouble with that is that it's then a serial hybrid, which is what I experimented with in my Electro-Metro.

There were a couple of things that I learned with that project. One is that engines are noisy and smelly and should be put under a hood with a real muffer and be on the other side of the firewall.

The other issue is that with a generator, it ONLY provides energy. It does NOT provide propulsion, heat, or a couple other things that an engine does.

By going with a Parallel Hybrid concept, I leave the engine under the hood, where it belongs. That way, I can still make use of its liquid cooling for winter cabin heat. I still use the the engine to push the vehicle down the road, and connect it to a typical (built-in) fuel system and exhaust.

I like the concept that I will be able to drive the vehicle on EITHER the diesel OR the electric motor. On a SERIAL Hybrid, if you have trouble with either one, you can't use the vehicle. On a parallel hybrid, either one can get you home.

On an EXPERIMENTAL DIY hybrid, redundant systems seem like a REALLY good idea.

|

|

|

|

|

The Following 3 Users Say Thank You to bennelson For This Useful Post:

|

|

12-05-2012, 11:05 PM

12-05-2012, 11:05 PM

|

#63 (permalink)

|

|

Zerg Lurker

Join Date: May 2008

Location: New York City

Posts: 44

Thanks: 5

Thanked 3 Times in 3 Posts

|

Ah, that answers my questions perfectly, thanks Ben!  |

|

|

|

12-06-2012, 04:21 PM

12-06-2012, 04:21 PM

|

#64 (permalink)

|

|

EcoModding Smurfer

Join Date: Aug 2012

Location: LaX

Posts: 293

Thanks: 52

Thanked 35 Times in 29 Posts

|

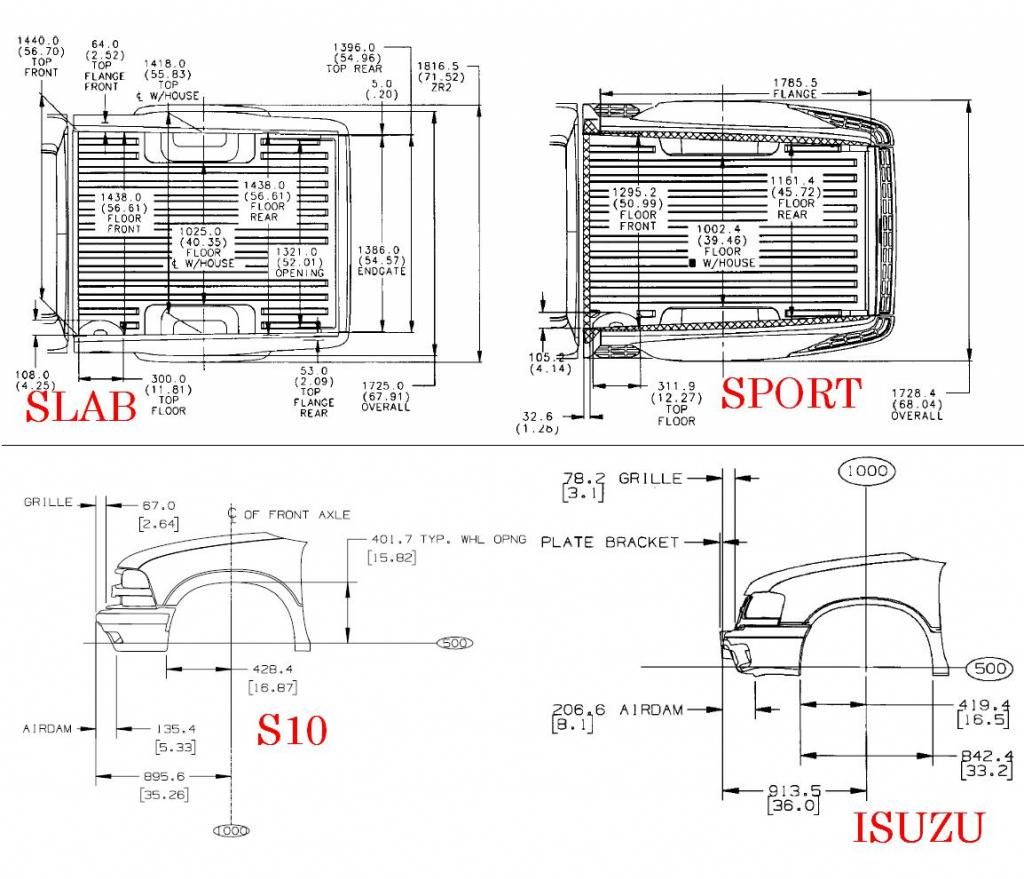

Ben, I was looking through that S10/Sonoma spec PDF that Slow_S10 linked to, and noticed a few possibilities to consider.

Our trucks are 1995s, but the body sizing is very close AFAIK to the 2001 the PDF details. The regular shortbox and the sportside are both about 76" long. Both boxes are 68" wide above the wheels, however the sportside tapers more to the rear, almost a full foot difference. Could that factor in when considering aerocaps? Maybe swap to a sportside, and smooth it out some? [[Page 31 & 34 on PDF]]

Also: Our generation (94-97) have different front ends than the 98+, but to swap fronts between generations you can change out the radiator support and it'll all bolt up (hopefully). From a side view, the Isuzu front end is significantly more slanted, and the S10/Sonoma/Bravada fronts are snub-nose. [[Page 27 & 28 on PDF]].

I understand low-cost is your goal, but maybe... just maybe... it's worth checking?

__________________

Last edited by Smurf; 12-06-2012 at 04:33 PM..

|

|

|

|

|

The Following User Says Thank You to Smurf For This Useful Post:

|

|

12-06-2012, 10:04 PM

12-06-2012, 10:04 PM

|

#65 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

Nice diagram image.

It's interesting to see them side by side like that. To me, the Sport Side has never looked very aerodynamic - more um, lumpy, than anything.

Good eye for details to notice that taper though! At this point, I'm not inclined to swap out a bed for what would likely be fairly minimal aero-gains.

About the front though. I don't see why I couldn't combine some sort of grill-block with slanty-ness. After the work I did for the grill block on my wife's car, I'm more likely to think that I could do something to help improve the front end.

Since I'm learning fiberglass right now, maybe by the time I get to the front, I'll know what I'm doing!

Did more fiberglass work today. 2 Nights ago, I dropped the flat cover off at my parent's house. Today, I headed over there and set up a pair of sawhorses in the heated shop. I set out the cover, bottom side up, to start working on fiberglassing the bottom.

I had some thick chopped matt strips (6 inch wide by 60" long). That material looked so thick, I didn't want to use too much of it, but I thought maybe extra strength at the edges would be a good idea...So....

I ran that 6" width around the four edges of the bottom of the cover. After that, I used what I had of the woven fiberglass cloth to cover the entire middle.

The two materials are slightly different to work with.

The matt is thick, and sucks up lots of resin. It's easy to handle, because it's pretty stiff, but the individual fibers also come out of it really easy. So, if I had ANY resin at all on my fingers, I quickly had fingers covered with fiberglass fur.

The cloth was a much lighter weight. It was easy to cover a big area quick, but then I had to make sure to keep tugging the cloth in the right direction to get the wrinkles out. It seemed to make good use of the resin, needing very little to hold it down and absorb all the way through.

I also Elmers glued the "step" edge.

I'm thinking that I'll use some of the thick 6"-wide matt on the flat back side of the lip. That way, I'll have something solid to cut into, and I can try to make the finished end of the curved edge look a little better.

Can anyone tell me a bit more about using body filler with fiberglass? The foam is so soft, it's hard to sand without either damaging the foam, or overdoing it, or taking forever and creating insane amounts of static-charged white dust.

If I want a fairly smooth and clean finish to the top, should I put down some fiberglass and then bondo over the top of that with something like a 6-foot-long straight-edge to even it all out? And then more fiberglass, or just paint over at that point. Any suggestions?

Last edited by bennelson; 12-06-2012 at 10:29 PM..

Reason: added photo

|

|

|

|

12-06-2012, 10:45 PM

12-06-2012, 10:45 PM

|

#66 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

I'd put a few layers of fiberglass on it to stiffen things up. Then you can start doing bondo work on it.

|

|

|

|

12-06-2012, 11:30 PM

12-06-2012, 11:30 PM

|

#67 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Western Wisconsin

Posts: 3,903

Thanks: 867

Thanked 434 Times in 354 Posts

|

Bondo with fiberglass tends to be heavy, I'd mix resin with coarse sawdust and make your own filler, it's easier to sand as well, you might be able to use crushed up foam bead board too if you just need a bulky filler.

|

|

|

|

12-06-2012, 11:33 PM

12-06-2012, 11:33 PM

|

#68 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

It will be interesting to see how rigid it is (or not) once I get a complete layer of fiberglass all the way around it.

I've heard good things about the strength of composites. Here's hoping for "torsion-box strength!"

I'm also thinking about adding "combination holes" to the underside of this.

The idea is that it would be some some sort of recess that would have a cross bar or something similar. That way, it could be a hole that the prop-stick could go in, but it could also serve as a tie-down point for safety-straps, or a lifting point when carrying it.

|

|

|

|

12-07-2012, 11:20 AM

12-07-2012, 11:20 AM

|

#69 (permalink)

|

|

Super Lurker!

Join Date: Sep 2012

Location: Chesapeake, VA

Posts: 88

Rusty - '88 Chevrolet S10 base 90 day: 23.72 mpg (US) Doc - '08 Honda Civic EX-L 90 day: 29.6 mpg (US)

Thanks: 4

Thanked 14 Times in 11 Posts

|

Quote:

Originally Posted by Smurf

Ben, I was looking through that S10/Sonoma spec PDF that Slow_S10 linked to, and noticed a few possibilities to consider.

Our trucks are 1995s, but the body sizing is very close AFAIK to the 2001 the PDF details. The regular shortbox and the sportside are both about 76" long. Both boxes are 68" wide above the wheels, however the sportside tapers more to the rear, almost a full foot difference. Could that factor in when considering aerocaps? Maybe swap to a sportside, and smooth it out some? [[Page 31 & 34 on PDF]]

Also: Our generation (94-97) have different front ends than the 98+, but to swap fronts between generations you can change out the radiator support and it'll all bolt up (hopefully). From a side view, the Isuzu front end is significantly more slanted, and the S10/Sonoma/Bravada fronts are snub-nose. [[Page 27 & 28 on PDF]].

I understand low-cost is your goal, but maybe... just maybe... it's worth checking?

|

Actually I think you might be on to something. You could get a step side bed ant then build some fillers that taper from the cab to the wheel wells then remove the steps behind the wheel wells and taper it all the way to the back. You could definitely end up with a very much improved aero bed. I have honestly never really cared for the step side bed look either but I think this has the potential to work really well.. although it may look fairly odd when you are done.

Also on swapping front ends, to install any of the 98+ S-series front ends just like you said all you just have to change out the radiator core support and all of the other parts just clip to it. And the bumpers bolt on in the exact same spots. The only other thing that you would have to change would be the wiring pigtails for the headlights.

But yeah in the s-10 community front end swaps are very common. When I had my old black S10 I would frequently swap between several different configurations. I had a full S10 front end, GMC front end and, Bravada front end, and on top of that the Bravada and GMC grilles also work with each other's bumpers. And I would just swap them out whenever I felt like doing something different. I always wanted to get an hombre front end but for that one you have to get the hood too since the s10/gmc hood is significantly different.

Just for giggles here is what a stock Hombre looks like:

And here is a S-10 Blazer with an Hombre front end installed:

And here is my old truck with the s10 front end installed:

and with the Bravada front end installed:

Now for what it's worth if you don't feel like going that far, swapping over to a 95-97 Blazer front end with the composite headlights would probably also improve the aero a little, but it is a direct bolt on to the core support that you have now.

Here is an example of an s10 with the Blazer composite headlights and grill:

PS: sorry for all the pictures... but I love pictures.

__________________

-Kevin

|

|

|

|

12-07-2012, 11:31 AM

12-07-2012, 11:31 AM

|

#70 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

I like the black low-rider S10. Good look.

As far as getting CRAZY with the back of a pickup truck....

Beds DO come completely off. I've always thought it was cool when somebody did a wood bed, in that classic pickup truck look.

It would be completely possible to make an entire bed/cap combination from scratch. That would potentially MAXIMIZE aero-improvements. It would just be a LOT of work!

An advantage is that since beds just bolt on, you could have a stock bed AND an "Aero-Bed" and (relatively) easily swap the two out.

That's a bit beyond what I'm planning on doing right now, but I'd love to see somebody do a complete from-scratch pickup back end like that.

|

|

|

|

|