09-23-2014, 02:18 AM

09-23-2014, 02:18 AM

|

#1141 (permalink)

|

|

Permanent Apprentice

Join Date: Jul 2010

Location: norcal oosae

Posts: 523

Thanks: 351

Thanked 318 Times in 215 Posts

|

Brilliant Work!

This demonstrates how a clean, elegant solution will always be better than the "big hammer" approach.

This should help with that issue of running out of processing time as the motor nears max rpm.

- E*clipse

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

09-24-2014, 07:51 PM

09-24-2014, 07:51 PM

|

#1142 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Here are a few pictures:

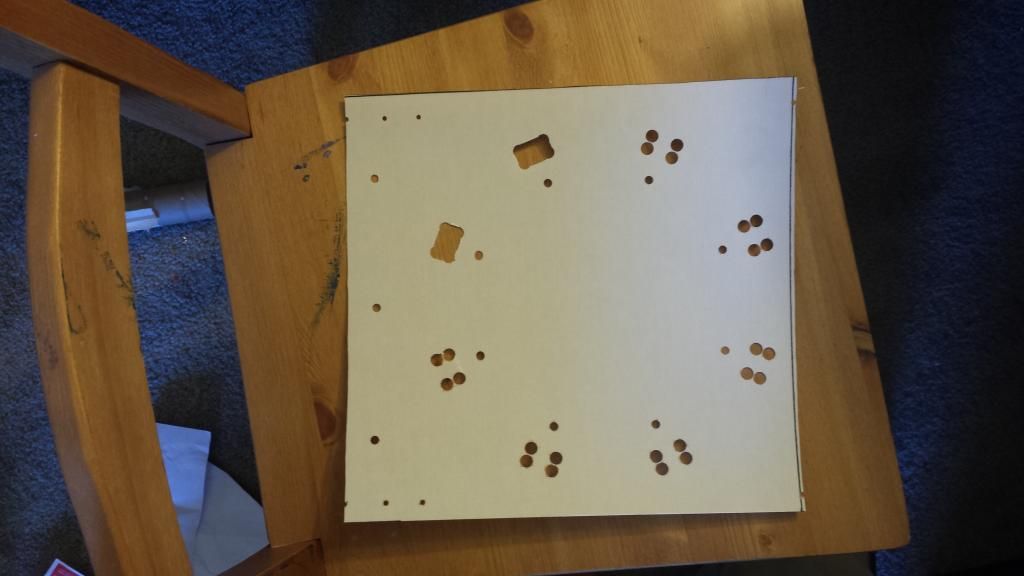

nomex isolation (I'm trying to avoid the weird shaped tabs on the ring capacitor, so i drill 4 holes, and then cut with little clippers):

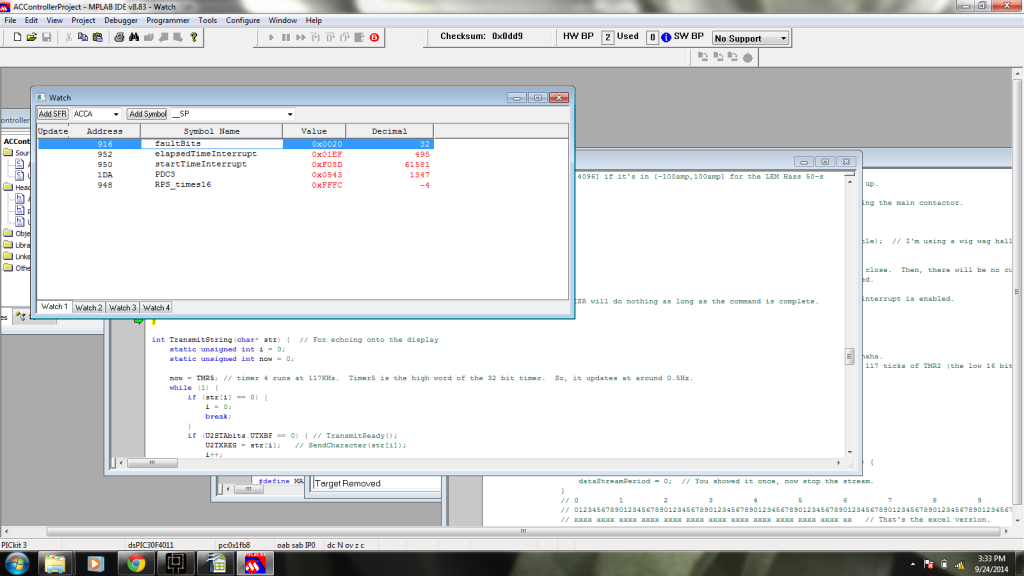

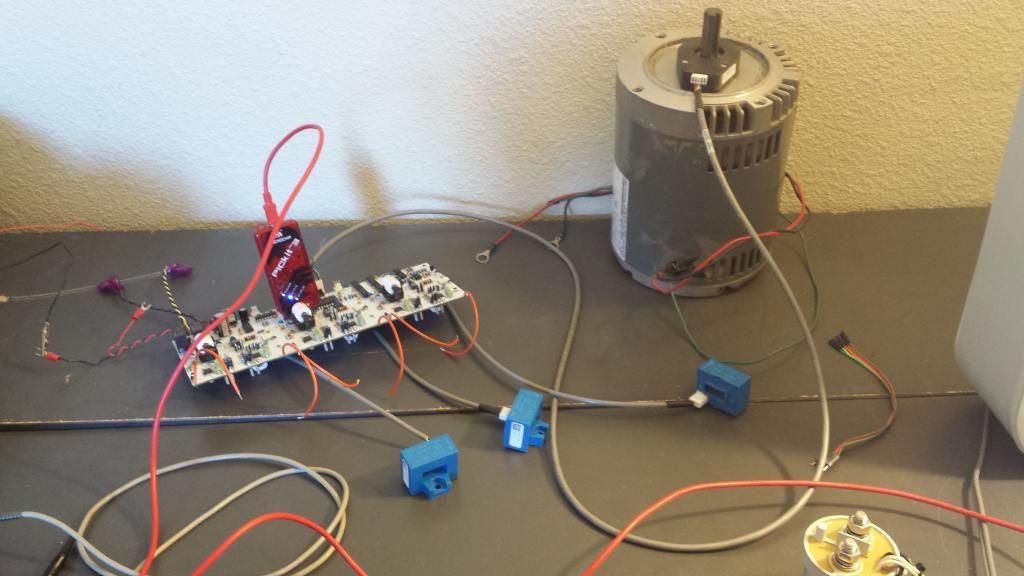

I tested the RPM and the encoder by hooking up a motor and spinning the post slowly with my hand:

One way it said negative, the other way it was positive! That's good. And it seemed to be accurate. I was spinning it slowly, and the units were revolutions/second * 16. It's *16 for extra resolution.

|

|

|

|

|

The Following 3 Users Say Thank You to MPaulHolmes For This Useful Post:

|

|

09-26-2014, 08:27 PM

09-26-2014, 08:27 PM

|

#1143 (permalink)

|

|

Permanent Apprentice

Join Date: Jul 2010

Location: norcal oosae

Posts: 523

Thanks: 351

Thanked 318 Times in 215 Posts

|

Yea! I'm making a bit of progress on that front as well.

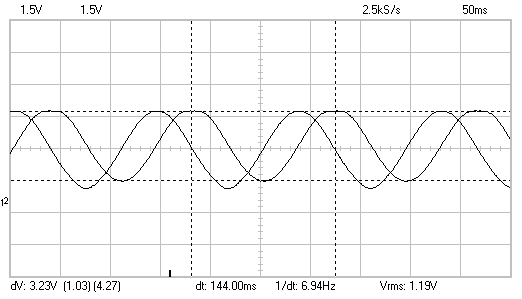

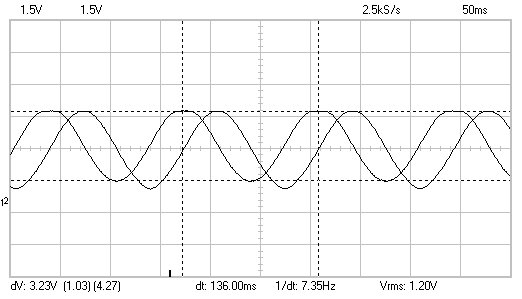

I've gotten both sin and cosine ouputs to work simultaneously. Here's a sample of the output. This output is actually a pair of waves formed from the tips of the carrier frequency. They are offset 90 degrees by the resolver. My circuit saves just the tips to form the waveforms shown in this 'scope capture.

Both were made by spinning the rotor as fast as I could by hand. In the first one, I spun the rotor clockwise and the speed reported on the scope is 6.94 Hz. The resolver puts out two cycles/revolution, so this works out to (6.94/2)(60) = 208.2 RPM. In the second pic, I spun the rotor counterclockwise, and the speed reported is 7.35 Hz, or 220.5 RPM. Notice how one wave is leading in one direction, or lagging in the opposite direction. I do need to make the waves the same amplitude and offset, but that's just tuning with resistors.

|

|

|

|

|

The Following 4 Users Say Thank You to e*clipse For This Useful Post:

|

|

09-28-2014, 10:44 PM

09-28-2014, 10:44 PM

|

#1144 (permalink)

|

|

Permanent Apprentice

Join Date: Jul 2010

Location: norcal oosae

Posts: 523

Thanks: 351

Thanked 318 Times in 215 Posts

|

This is kind of off topic, yet it's on topic. It's not AT ALL addressed at any one or any thing that has happened with this project. It's merely a rant against shotty workmanship and allowing the accounting department to make critical decisions...

It's on topic because recently we had a conversation about necessary capacitance, and because I have been spec'ing components for the resolver decoder.

For a while now, I've noticed various electronic gadgets fail because of a power supply failure. They will inexplicetly not power up, or cycle on and off rapidly.

I've had a bunch of LED lights do this, which for an ecologically minded person is pretty frustrating. They are supposed to be ecologically friendly because they use little energy and because they're supposed to last a long time - virtually indefinitely. The LED lights will fail by blinking at about 60hz. Sometimes they warm up and stabilize, but eventually, they will just blink.  This is about after one year or even shorter. Not good for something that's supposed to have a 10yr + life span. Especially not good because there are obviously a lot more resources involved with one of these light bulbs when compared to an incandescent light.

I've suspected these devices have failed because they underspec'd a critical capacitor in the power supply. It's very easy to do this with cheap electrolytic capacitors.

To test this, I tore apart one of those LED lights. Unfortunately, the way it was made, you couldn't take it apart without breaking the case. BTW, the case had a very impressive heat sink/fin setup so the LED's could stay cool and not fail prematurely.

Inside this light bulb was a TINY switch mode power supply. The power supply had no way to dissipate heat. It was not connected AT ALL to the heat sink and was wrapped in tape and covered with a case that allowed no air movement. The workmanship was a little shoddy, especially when compared to the heat sink. As I suspected, there was a relatively large 4.7uF electrolytic capacitor. Upon further inspection, I found the Mosfet (the main power switch) with no way to connect its heat sink to anything..... -no I can't believe this - except the bottom of the electrolytic capacitor!!

What a bunch of idiots - the main heat generating device in the power supply is directly connected to the ONE thing that needs protection from excess heat....

Just to see if I was right, I grabbed a giant 470uF capacitor out of my parts bin and replaced the 4.7uF capacitor with it.

la LA la la - - the light works! Too bad I destroyed it while taking it apart.

So, back to our project. What brings this up is I was spec'ing a 10uF capacitor for my circuit. For $1.00 you can purchase a ceramic surface mount capacitor with an infinite life. For $0.44 you can spec the cheapest electrolytic option, with a 100C maximum temperature and a 1000 hr. life.

Is saving the $0.56 worth it? Not in my opinion. It's annoying for your kitchen lights to fail, but if this circuit fails, you'll be sitting by the side of the road, wondering what happened...

It may be tempting when spec'ing parts for your car ( say this motor controller ) to save money on each little part, adding up to perhaps some significant cups of coffee. On the other hand, you might consider the reliability of your transportation as more important.

MIL spec? A little over the top. OTOH, automotive & high reliability parts are definitely worth it.

- E*clipse |

|

|

|

|

The Following 2 Users Say Thank You to e*clipse For This Useful Post:

|

|

09-29-2014, 09:08 AM

09-29-2014, 09:08 AM

|

#1145 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

That is an engineering crime. Why don't they advertise the LED bulb as 1000 hours, due entirely to a 10 cent 1000 hour life part. It sounds intentional. These dang LEDs last forever. How can we put a limited life on them? Why don't they just add a timing circuit, set to 1000 hours. After the time limit, a relay opens for no good reason, and the part ceases to work. At least then they wouldnt have to mask the intentional failure as incompetence. In modest bulk, 22uf MLCC caps in the controller are like 25 cents each. Their life is rated for 6700 years (24 hours per day at rated temperature I believe, which is friggen 125 degC). You could run it in boiling water until we are all morlochs and eloi. LOL.

IIt's a shame, because I've heard that the led bulbs have a limited life, and always wondered why. It's intentional.

|

|

|

|

09-29-2014, 10:27 AM

09-29-2014, 10:27 AM

|

#1146 (permalink)

|

|

Master EcoModder

Join Date: Jun 2009

Location: SC Lowcountry

Posts: 1,796

Thanks: 226

Thanked 1,353 Times in 711 Posts

|

.

Quote:

e*clipse

This is kind of off topic, yet it's on topic. It's not AT ALL addressed at any one or any thing that has happened with this project. It's merely a rant against shotty workmanship and allowing the accounting department to make critical decisions...

For a while now, I've noticed various electronic gadgets fail because of a power supply failure. They will inexplicetly not power up, or cycle on and off rapidly.

For a while now, I've noticed various electronic gadgets fail because of a power supply failure. They will inexplicetly not power up, or cycle on and off rapidly.

I've suspected these devices have failed because they underspec'd a critical capacitor in the power supply. It's very easy to do this with cheap electrolytic capacitors.

Inside this light bulb was a TINY switch mode power supply. The power supply had no way to dissipate heat. It was not connected AT ALL to the heat sink and was wrapped in tape and covered with a case that allowed no air movement. The workmanship was a little shoddy, especially when compared to the heat sink. As I suspected, there was a relatively large 4.7uF electrolytic capacitor. Upon further inspection, I found the Mosfet (the main power switch) with no way to connect its heat sink to anything..... -no I can't believe this - except the bottom of the electrolytic capacitor!!

What a bunch of idiots - the main heat generating device in the power supply is directly connected to the ONE thing that needs protection from excess heat....

|

Quote:

MPaulHolmes

That is an engineering crime. Why don't they advertise the LED bulb as 1000 hours, due entirely to a 10 cent 1000 hour life part. It sounds intentional. These dang LEDs last forever. How can we put a limited life on them? Why don't they just add a timing circuit, set to 1000 hours. After the time limit, a relay opens for no good reason, and the part ceases to work. At least then they wouldnt have to mask the intentional failure as incompetence. In modest bulk, 22uf MLCC caps in the controller are like 25 cents each. Their life is rated for 6700 years (24 hours per day at rated temperature I believe, which is friggen 125 degC). You could run it in boiling water until we are all morlochs and eloi. LOL.

IIt's a shame, because I've heard that the led bulbs have a limited life, and always wondered why. It's intentional.

|

Planned obsolescence...

> |

|

|

|

|

The Following 3 Users Say Thank You to redneck For This Useful Post:

|

|

09-29-2014, 07:45 PM

09-29-2014, 07:45 PM

|

#1147 (permalink)

|

|

Dreamer

Join Date: Nov 2013

Location: Australia

Posts: 350

Thanks: 95

Thanked 214 Times in 151 Posts

|

Quote:

Originally Posted by MPaulHolmes

That is an engineering crime. Why don't they advertise the LED bulb as 1000 hours, due entirely to a 10 cent 1000 hour life part. It sounds intentional. These dang LEDs last forever. How can we put a limited life on them? Why don't they just add a timing circuit, set to 1000 hours. After the time limit, a relay opens for no good reason, and the part ceases to work. At least then they wouldnt have to mask the intentional failure as incompetence. In modest bulk, 22uf MLCC caps in the controller are like 25 cents each. Their life is rated for 6700 years (24 hours per day at rated temperature I believe, which is friggen 125 degC). You could run it in boiling water until we are all morlochs and eloi. LOL.

IIt's a shame, because I've heard that the led bulbs have a limited life, and always wondered why. It's intentional.

|

Laziness, indifference and cost.

I would bet the factory that put that light together did so with whatever were the cheapest components/modules that would work. Some other factory probably made the switchmode supply for some other purpose and the LED factory could get them real cheap seeing as they have no electrical isolation or some other issue. The designer at the LED factory is then told to get it to work without spending a cent. So he chucks some electrical tape around it to stop it shorting out straight out of the box.

Tells the boss the circuit will only last a couple of years and the boss says well done.

Fire up the production line, cheap switch mode supply, no failure within the time the customer can come back to them for their money back. Boss is happy. They sell heaps of them because they are 10 cents cheaper than everybody else.

This is not the device you want to buy.

If you are lucky you find a factory that was producing stuff for a company that had high quality control standards and the entire device was designed rather than cobbled together from whatever was handy/cheap.

That fatory produced the quantity that the company contracted them for but once the production line is up and running they don't shut it down when they reach their quota. No they keep making the device, then they sell them direct on eBay or something. Undercutting the company that designed the device.

That is the device you hope to get.

Cheap because it is a rip off of somebody else's work not because it is made of cheap parts to a cheap design.

And now for something more on topic.

Forward and reverse on a 3 phase motor.

Am i right in thinking that the controller can be asked to reverse the motor direction or you can just swap any two of the phase cables to reverse the motor direction?

Just want to make sure the default motor direction is the correct direction for the gearbox.

I don't need 5 reverse gears.

Paul what happens to the controller if it tries to spin the motor in one direction but the encoder says it is spinning the other direction? Does it care about encoder direction or just relative movement of the encoder?

Astro |

|

|

|

|

The Following User Says Thank You to Astro For This Useful Post:

|

|

09-29-2014, 10:48 PM

09-29-2014, 10:48 PM

|

#1148 (permalink)

|

|

Permanent Apprentice

Join Date: Jul 2010

Location: norcal oosae

Posts: 523

Thanks: 351

Thanked 318 Times in 215 Posts

|

This video is fascinating.

As an engineer and "consumer" I've had my suspicions about this for a long time.

I'm thinking of moving this discussion to another place in ecomodder - which I think is the perfect place for such a discussion - another area.

Suggestions?

- E*clipse

Quote:

Originally Posted by redneck

.

Planned obsolescence...

> |

|

|

|

|

09-29-2014, 11:44 PM

09-29-2014, 11:44 PM

|

#1149 (permalink)

|

|

Master EcoModder

Join Date: Sep 2010

Location: Saskatoon, canada

Posts: 1,488

Thanks: 746

Thanked 565 Times in 447 Posts

|

Quote:

Originally Posted by Astro

Forward and reverse on a 3 phase motor.

Am i right in thinking that the controller can be asked to reverse the motor direction or you can just swap any two of the phase cables to reverse the motor direction?

Just want to make sure the default motor direction is the correct direction for the gearbox.

I don't need 5 reverse gears.  |

The controller can reverse by changing the phase, forward is for example A,B,C and reverse can exchange any two, say A,C,B

Not sure about Paul's code - may require a small tweak to allow either direction to be default? |

|

|

|

09-30-2014, 12:47 AM

09-30-2014, 12:47 AM

|

#1150 (permalink)

|

|

Dreamer

Join Date: Nov 2013

Location: Australia

Posts: 350

Thanks: 95

Thanked 214 Times in 151 Posts

|

Quote:

Originally Posted by thingstodo

The controller can reverse by changing the phase, forward is for example A,B,C and reverse can exchange any two, say A,C,B

Not sure about Paul's code - may require a small tweak to allow either direction to be default?

|

Shouldn't be a problem, i will just check the wheel direction while it is up on stands and swap 2 connections if it is going the wrong way.

Hopefully Paul's code is direction independent. So can work with the encoder spinning either direction.

What i mean is that say the controller tries to turn the motor clockwise, and the motor (and encoder) turn clockwise. Then i find that is the wrong direction for the gearbox and so swap a couple of phases. Then when the controller tries to turn the motor clockwise it actually rotates counter-clockwise and obviously the encoder does as well.

Will this upset the software or is it just looking for a degree of movement and it is not concerned if that degree is a positive or negative change.

|

|

|

|

|