01-12-2012, 01:41 PM

01-12-2012, 01:41 PM

|

#5421 (permalink)

|

|

EcoModding Apprentice

Join Date: Mar 2011

Location: alaska

Posts: 141

Thanks: 10

Thanked 37 Times in 19 Posts

|

it's going to be a hybrid of your logic board, adam's power stage, and my bus bars/enclosure. i'll let you know!

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-12-2012, 01:52 PM

01-12-2012, 01:52 PM

|

#5422 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

I really liked Paul's logic board on the 1000 Amp controller. It was nicely laid out, clean, and included an automated pre-charge right on there.

It still worked great, even after I totally blew the power stage.

Last edited by bennelson; 01-12-2012 at 03:24 PM..

Reason: possesive type

|

|

|

|

01-12-2012, 02:10 PM

01-12-2012, 02:10 PM

|

#5423 (permalink)

|

|

ReVolt Enthusiast

Join Date: Jun 2009

Location: Michigan, USA

Posts: 239

Thanks: 97

Thanked 47 Times in 40 Posts

|

Quote:

Originally Posted by DJBecker

Our controller has software-only overcurrent control, which means we are much more careful about it. (Plus we had two batches of counterfeit IR MOSFETs which caused us to rewrite the limit code a few times.)

We check just before setting the PWM register, and skip the next PWM cycle (set the width to 0) whenever the current is above the limit.

This is a separate, explicit check that is not part the normal control loop. That way changing the control loop constants won't accidentally defeat the current limit.

We hit the current limit frequently, and can tell immediately by the hissing noise from the motor that results.

We also clamp the MOSFET to the live bus bar. We haven't seen any gate drive issues from that configuration, even with one DC-DC converter and a single gate driver driving all of the MOSFETs. It may be because we run a twisted pair from the gate driver board to each MOSFET. The actual connection to the MOSFET pins is made with a tiny (0.5"x0.325") circuit board that has a 10R gate resistor and 1R0 source resistor.

That reminds me, you might consider adding a gate drive LED for debugging.

Our gate connection circuit board has pads for a TVS (SMBJ12A), and a LED+resistor (both 0805 size). The LED is only installed on the end MOSFET board. Even pointed the wrong way, the reflected glow lets us know that the gate driver is working during tests. In retrospect, we should have put LEDs on the gate driver board itself, but they had already been made.

|

DJBecker,

Thank you for your shared knowledge.

Have you posted any Photos or Specs of your controller and driver PCB on this forum ??? If not could you ??? Clamp your MOSFET's to the bus bars for testing or assembly ???

Thanks,

-Mark  |

|

|

|

01-12-2012, 02:38 PM

01-12-2012, 02:38 PM

|

#5424 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Quote:

Originally Posted by bennelson

I really liked Paul'f logic board on the 1000 Amp controller. It was nicely laid out, clean, and included an automated pre-charge right on there.

It still worked great, even after I totally blew the power stage.

|

There really is absolutely no connection between the power stage and control stage other than the control stage sending light across the void to the power stage (by LEDs inside the optocoupler) to tell it what to do. If something fails, the little beams of light to the power stage just don't do anything anymore. I don't think there's any possible way for the control board to be damaged by a naughty power stage. |

|

|

|

01-12-2012, 08:06 PM

01-12-2012, 08:06 PM

|

#5425 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2010

Location: Annapolis

Posts: 159

Thanks: 0

Thanked 32 Times in 27 Posts

|

Quote:

Originally Posted by sawickm

DJBecker,

Thank you for your shared knowledge.

Have you posted any Photos or Specs of your controller and driver PCB on this forum ??? If not could you ??? Clamp your MOSFET's to the bus bars for testing or assembly ???

|

By "clamp" I mean using spring heat sink clips e.g. MAXCLIP08G. We clean the back of the MOSFET, polish the bus bar, spread a little anti-oxidant grease, and screw down using a hole drilled and tapped into the bus bar.

Each MOSFET has the tiny gate drive connection board slid onto its leads, then the source pin is soldered to a tinned copper strip that makes the connection to the adjacent bus bar.

I think I've posted the board outline of the gate driver and STM32 controller boards before, but I'll do it again this evening if there is interest.

Update: Here is the post with the gate driver board.

http://ecomodder.com/forum/showthrea...tml#post238466

Last edited by DJBecker; 01-12-2012 at 09:07 PM..

|

|

|

|

01-13-2012, 09:08 AM

01-13-2012, 09:08 AM

|

#5426 (permalink)

|

|

ReVolt Enthusiast

Join Date: Jun 2009

Location: Michigan, USA

Posts: 239

Thanks: 97

Thanked 47 Times in 40 Posts

|

Quote:

Originally Posted by DJBecker

By "clamp" I mean using spring heat sink clips e.g. MAXCLIP08G. We clean the back of the MOSFET, polish the bus bar, spread a little anti-oxidant grease, and screw down using a hole drilled and tapped into the bus bar.

|

Ok, you are using the same technique that Paul uses on his MOSFET/Busbar assembly.

Quote:

|

Each MOSFET has the tiny gate drive connection board slid onto its leads, then the source pin is soldered to a tinned copper strip that makes the connection to the adjacent bus bar.

|

Do you have to worry about vibration cracking the solder joint from the soldered source pin - copper strip - busbar connection? I might not be visualizing that correctly?

Quote:

|

I think I've posted the board outline of the gate driver and STM32 controller boards before, but I'll do it again this evening if there is interest.

|

You did post info on your gate driver, but I don't remember seeing your STM32 controller PCB. I would be interested in seeing your controller PCB, and your assembled unit too.

Thanks,

-Mark  |

|

|

|

01-13-2012, 08:29 PM

01-13-2012, 08:29 PM

|

#5427 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2010

Location: Annapolis

Posts: 159

Thanks: 0

Thanked 32 Times in 27 Posts

|

Our motor control board is based on a STM32 processor in a 64 pin package. The lower section is has a 5V regulator and CAN transceiver. It's isolated from the upper section with a DC-DC converter and a Si8421 2 channel digital isolator.

|

|

|

|

|

The Following User Says Thank You to DJBecker For This Useful Post:

|

|

01-13-2012, 08:58 PM

01-13-2012, 08:58 PM

|

#5428 (permalink)

|

|

AC-DC enthusiast

Join Date: Nov 2009

Location: Long Island, NY

Posts: 282

Thanks: 123

Thanked 54 Times in 37 Posts

|

Quote:

Originally Posted by DJBecker

Our motor control board is based on a STM32 processor in a 64 pin package. The lower section is has a 5V regulator and CAN transceiver. It's isolated from the upper section with a DC-DC converter and a Si8421 2 channel digital isolator.

|

WOW, it's really tiny....

__________________

. .. .. . .... . .... ... ...

Prius Absolutum Dominium . ..........KOPPER

PHEV conversion since Dec 2006.. . .... .Future EV

. . . . . . . .CALCars # 27. . . . . . . . . . ..on the works now !!

. . . . . . . . . . . . . . . . .. . ........

|

|

|

|

01-13-2012, 10:35 PM

01-13-2012, 10:35 PM

|

#5429 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Man that is beautiful!

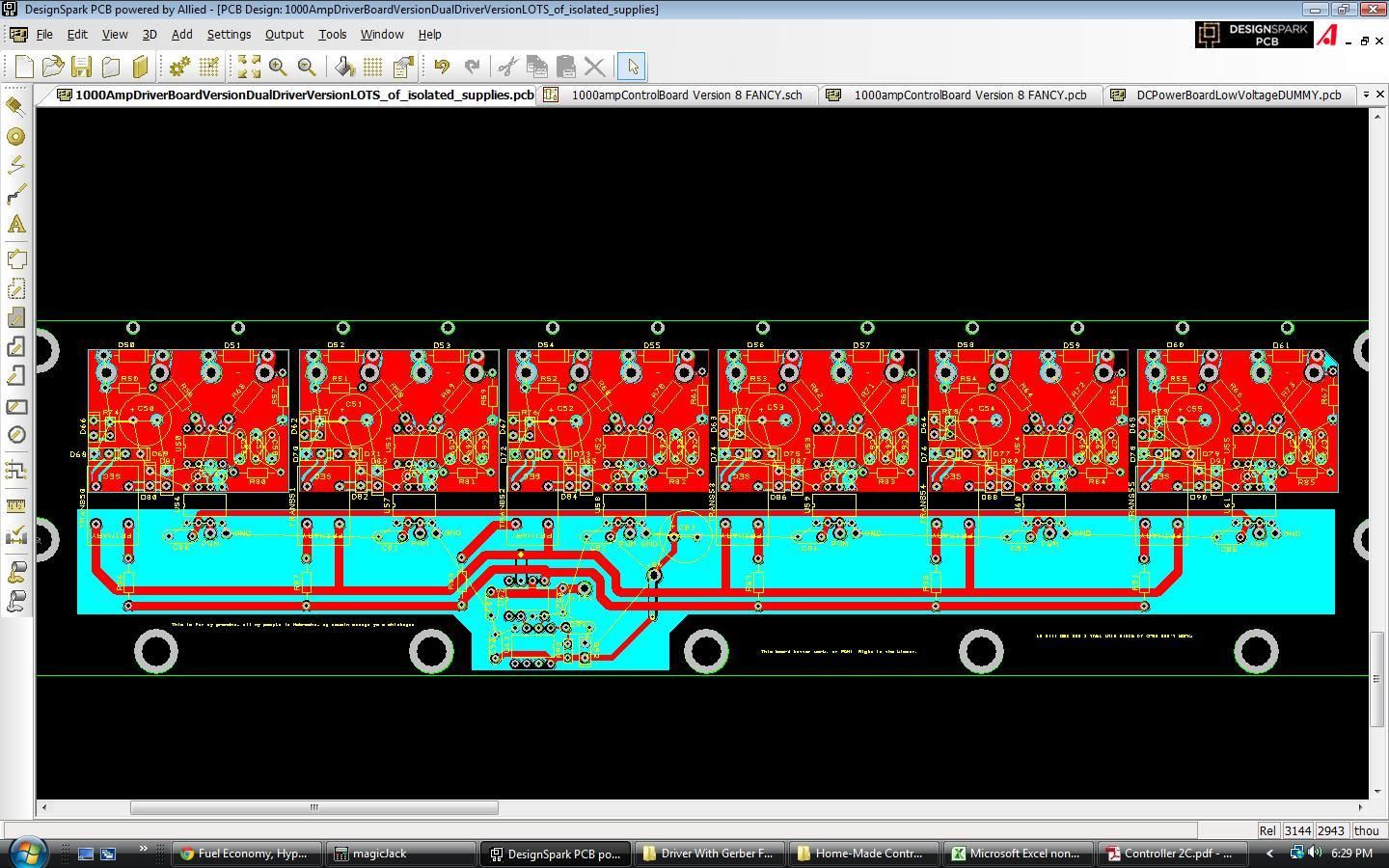

I sent in 2 files for new control and driver boards today. Adam had told me about the $33 for a single board thing they do, so I'm trying that. The power board is just going to have to wait until later, because it's friggen expensive to get the setup fee paid for it. So, this one will use the left over power board. I still want to try a high side power board, and I finished making one on the computer, but I think Joe's idea of just using what's already available makes a lot of sense.

On the new board, it has the "watchdog for the watchdog" feature. haha. You know, disable the mosfet driver if the microcontroller freezes up for more than 0.001 seconds. That circuit is tested and working. Also, it has adjustable hardware overcurrent trip point from about 50 amps up to around 1200 amps. I'm also going to change the code to allow for any max current you want. And for now, if the overcurrent trip point happens, it's going to flag a fault so that you have to lift the foot all the way off the throttle to clear it. Eventually the hardware overcurrent should never come on anyway.

I'm using 6 shielded twisted pairs to go to each pair of mosfets on the driver board from the control board. Every path is as short as the packages I'm using will allow. Each mosfet has its own driver. The distance from mosfet driver output to mosfet leg is only the length of the body of the gate resistor. It can't be shorter with through hole parts.

6 isolated supplies. Unnecessary? Yes! hahaha. But I can use the driver boards unchanged in an AC controller too. Or a high side controller, or brushless DC controller. I also did a version that uses negative voltage on turnoff in case you want to use TO-247 package IGBTs instead, or just want the turn on and turn off of the mosfets to be the same.

I did some rewinding experiments with the line filters. They are VERY rewindable. Removing 5 wraps on the primary changed the result from 12v in, 4 supplies of 10.5v out, to 12v in, 4 supplies of 12.4v out. They agreed to +/- 0.005v.

I"m also going to change the software to allow Ben to have slower ramp up. Like as low as 62.5 amps per second if you floor it, all the way up to thousands of amps per second from flooring it. I still don't get why Ben's controller was so sensitive to the throttle though. |

|

|

|

01-14-2012, 12:19 AM

01-14-2012, 12:19 AM

|

#5430 (permalink)

|

|

EcoModding Apprentice

Join Date: Nov 2010

Location: Annapolis

Posts: 159

Thanks: 0

Thanked 32 Times in 27 Posts

|

Quote:

Originally Posted by mrbigh

WOW, it's really tiny....  |

It's 1.5" by 1.75". There is no wasted space, and it doesn't cost a lot to make.

That's our May 2011 board. We've learned a bit and improved it since then, but there hasn't been a motivation to have new boards made.

We spent quite a bit of time on the layout and made a few compromises to keep all signals on the top layer. The bottom layer is entirely a ground plane.

The left side is the "quiet side" with 8 analog inputs. The top three have resistor dividers for higher voltage signals.

The right side has four outputs, driven by two dual MOSFETs in SO-8 packages. The MOSFETs are logic level drive and are rated at 9.1 amps per channel.

Each input and output has the same three pin layout. Pin 1 (always on the outer edge) is a ground, pin 2 power and pin 3 the signal. Six of the analog inputs have 3.3V power (for temperature sensors and throttle), with the bottom two have 5V power for the current sensors. All of the MOSFET-driven outputs have 5V power.

Since the ADC has a 3.3V maximum input, we orient the current sensors so that increasing current drops the output voltage: zero current has a 2.5V output dropping to about 1.0V at maximum current.

The four pin connections in the middle are the motor PWM output (ground, +5V, and both low and high side signals) and a SWD program/debug header. We program using a ST-Discovery development board which is well under $20.

The motor controller is voltage isolated from the chassis ground, and it uses an isolated gate driver. That gives us the option of changing it to be traction voltage referenced, or just leave it fully isolated for safety.

|

|

|

|

|