08-25-2013, 04:23 AM

08-25-2013, 04:23 AM

|

#211 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Today I built my controller cooling system.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

08-26-2013, 12:06 PM

08-26-2013, 12:06 PM

|

#212 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

Cool. Tell us again about that Ikea shelving you're using to mount stuff on. Is it coated particle board? Some other mystery material?

|

|

|

|

08-26-2013, 04:32 PM

08-26-2013, 04:32 PM

|

#213 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Quote:

Originally Posted by MetroMPG

Cool. Tell us again about that Ikea shelving you're using to mount stuff on. Is it coated particle board? Some other mystery material?

|

Yup, just painted 5/8" particle board. Go to the As Is section and you can buy a nice 4X6 piece for about $3. WAY cheaper than a hardware store. I make all my storage shelves with it too. |

|

|

|

09-15-2013, 02:27 AM

09-15-2013, 02:27 AM

|

#214 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

I got my new coupler back from my machinist friend, Matt. Once again Matt proved his brilliance and made me another work of art.

I quickly got to work installing the tachometer pickup sensor. The two bolts on the coupler will spin past the sensor, acting like the pickup that used to be in the distributor.

Why two bolts? Because this will be measuring "crankshaft" speed which spins twice as fast as distributor speed, so it needs half as many pickup teeth as it used to have.

Another bit of fabrication that I needed to do for my new motor is the right side motor mount. In the end I just decided to weld a bolt onto the bearing cover. It really doesn't look very strong, but since the transmission has three mounts, all this mount does is hold the motor in the correct position. There isn't much weight on it.

Today I put everything back together, except for tying up wiring because I ran out of zip ties. I then ran the motor for an hour at just over 2000 rpm to break the old brushes in. I figured it would be a good idea since I moved the brush holder, and I may not have got it perfectly centred with the armature.

Here is a video:

|

|

|

|

09-16-2013, 01:38 AM

09-16-2013, 01:38 AM

|

#215 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

IT'S ALIVE (Again)

Since I do not have insurance on the car I drove it around my complex. The new motor is EERILY silent. My old sepex motor made lots of comm noise under coast and light loads, which was likely because of field current that was always going, inducing voltage in the armature that had nowhere to go.

I also noticed that it has more torque than before. Having a functional tachometer is another wonderful perk. I only got it up to maybe 10 mph and a proper test drive will not happen for quite some time because I am still in motorcycle mode and don't want to insure both bike and car at the same time if I don't have to.

|

|

|

|

09-16-2013, 10:35 AM

09-16-2013, 10:35 AM

|

#216 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

Quote:

Originally Posted by mechman600

I also noticed that it has more torque than before...

|

And THAT'S why we love DIY series-wound motor conversions!

The urge to "burn rubber" will start to become overwhelming soon. |

|

|

|

09-16-2013, 10:47 AM

09-16-2013, 10:47 AM

|

#217 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

Woohoo! Nice going, James.

I'm really looking forward to your first "real" drive report.

On the coupler, did you use the pump shaft? What about your concerns with its diameter where it necked down?

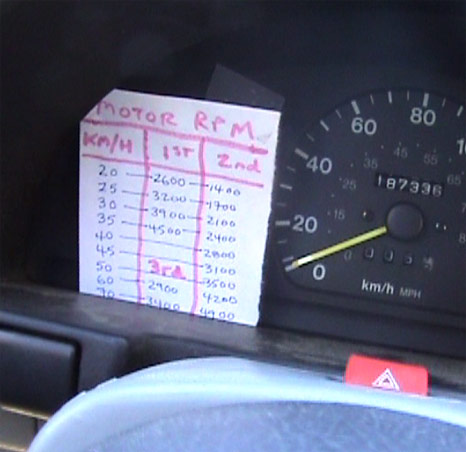

For your amusement, the ForkenSwift's tachometer:

|

|

|

|

09-16-2013, 10:49 AM

09-16-2013, 10:49 AM

|

#218 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

Also, FYI, I operated under the assumption that 5000 RPM was the redline, but I rarely if ever got that high.

Most of the time I just drive around in 3rd gear, so the motor pretty much exists below ~2500 RPM.

|

|

|

|

09-16-2013, 10:53 AM

09-16-2013, 10:53 AM

|

#219 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Quote:

Originally Posted by MetroMPG

On the coupler, did you use the pump shaft? What about your concerns with its diameter where it necked down?

|

Yes, I ended up using the pump shaft. I am quite concerned about the small diameter but decided to go with it for now. If it breaks, it breaks and I will deal with it then.

One of the deciding factors is the fact that I am only running 12.5% more amps than the Forkenswift, so 12.5% more torque, all efficiency variables aside. And yours has lasted a long time.

Quote:

|

For your amusement, the ForkenSwift's tachometer:

|

Wow...that's the same exact one I was using till now! |

|

|

|

09-16-2013, 10:58 AM

09-16-2013, 10:58 AM

|

#220 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,534

Thanks: 4,082

Thanked 6,979 Times in 3,614 Posts

|

You should be fine if you can resist trying to do burnouts with the new motor.  (I only ever tried in gravel.)

And, yeah, I love the sound of this motor. It has a Jetsons vibe. Sometimes I drop a gear to enjoy it. (Just like I do when I drive my Ferarri through tunnels & underpasses.)

|

|

|

|

|