03-20-2008, 11:45 AM

03-20-2008, 11:45 AM

|

#21 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Thanks for the suggestion Otto. Well, its a front wheel drive car, so I'd need larger tires on the front. But, I don't want to throw off my speedo/odometer. I'd just rather do it the right way. If I swap in a new diff the speedo stays right and I get to crack open a tranny which I've never done. If price were a major concern, I probably wouldn't even be thinking about doing as much as I currently am. If ease of the work was a concern I also wouldn't think about doing a smuch as I am. This is a fun thing that I enjoy, challenges me, and makes me learn.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

03-20-2008, 01:31 PM

03-20-2008, 01:31 PM

|

#22 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

So, I was reading Hucho on my lunch hour and came across a very nice little chart that plotted rear vehicle taper angle (off horizontal) versus Cd. Of course my own car immediately pops into mind and I must measure to get a good idea of how bad things are. Well, it turns out things AREN'T very bad at all! I went and grabbed a side view of a Paseo and popped it into my CAD software. Looks like my rear windshield angle is roughly 16.7°. According to the chart the optimum is very near 15°. Hurray for the Paseo for being pretty darn close.

Of course, this brings up the idea of rear spoiler removal... we'll get to that later.  |

|

|

|

|

The Following User Says Thank You to Daox For This Useful Post:

|

|

03-26-2008, 08:33 AM

03-26-2008, 08:33 AM

|

#23 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Okay, I finally got a chance to look through the service manual. According to it, the thermostat should start to open up at 176-183°F. So, it looks like I'm going to be needing a new thermostat.

I also looked up at what temp my fan kicks in and its no big surprise that its on at 201°F. This is about the max temp I have hit so far. So, it sounds like my fan is probably kicking in quite a bit. I wish there was an easy way to monitor when its on vs off. I thought about splicing in a relay that powered a light, but I'd rather not cut into the wiring. In any case, I need to get the temp back down so I can go ahead with the aero mods and such.

|

|

|

|

03-26-2008, 11:06 AM

03-26-2008, 11:06 AM

|

#24 (permalink)

|

|

Master EcoModder

Join Date: Mar 2008

Location: USA

Posts: 568

Thanks: 1

Thanked 73 Times in 58 Posts

|

Quote:

Originally Posted by Daox

Okay, I finally got a chance to look through the service manual. According to it, the thermostat should start to open up at 176-183°F. So, it looks like I'm going to be needing a new thermostat.

I also looked up at what temp my fan kicks in and its no big surprise that its on at 201°F. This is about the max temp I have hit so far. So, it sounds like my fan is probably kicking in quite a bit. I wish there was an easy way to monitor when its on vs off. I thought about splicing in a relay that powered a light, but I'd rather not cut into the wiring. In any case, I need to get the temp back down so I can go ahead with the aero mods and such.

|

Once you assure that your thermostat is working correctly, or install another T-stat with somewhat higher heat range, you may want to reconsider the amount of radiator blockage you have installed.

A small elliptical inlet (long axis horizontal) at the stagnation point on the nose of the car will add little or no drag, yet let the radiator breathe better. Proper outlet of cooling air is just as important (or moreso) than inlet design. A quick tuft test will tell you the stagnation point at highway speed. Unfortunately, this is at the license plate mount in many cars, and may mean moving the license plate.

NACA did a lot of work on cowl flaps and outlets for recip. engines during WWII, taking the best ideas from aircraft of any country, including Germany and Japan. Geometry of outlets back into the slipstream is a big deal, as the outlet acts like the gills of a fish--drawing the spent cooling air out via Venturi effect, a much more subtle and efficient method than brute force ramming it down the inlet throat. Fast fishes like tuna and shark would not be fast (or get breakfast) if they had to swim with their mouths wide open. Instead, they'd be breakfast. |

|

|

|

03-26-2008, 11:21 AM

03-26-2008, 11:21 AM

|

#25 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Very good points Otto, and just what I had planned. Just yesterday I was wondering how many pieces I'll need for the tuft testing and thinking about what colors to use on the body and windshield for maximum viewability.  But, I hadn't thought about the reintroduction of airflow. I was kind of thinking that with the bellypan the only exit for air will be the wheel wells. This is what Basjoos is currently doing. |

|

|

|

03-26-2008, 11:47 AM

03-26-2008, 11:47 AM

|

#26 (permalink)

|

|

Master EcoModder

Join Date: Mar 2008

Location: USA

Posts: 568

Thanks: 1

Thanked 73 Times in 58 Posts

|

Quote:

Originally Posted by Daox

Very good points Otto, and just what I had planned. Just yesterday I was wondering how many pieces I'll need for the tuft testing and thinking about what colors to use on the body and windshield for maximum viewability.  But, I hadn't thought about the reintroduction of airflow. I was kind of thinking that with the bellypan the only exit for air will be the wheel wells. This is what Basjoos is currently doing. |

Tuft testing on a motorcycle is easy since you can sit there and see the yarn. On a car, you'd presumably need a photographer in another vehicle at highway speed. At the nose, only a dozen or so tufts required.

Lots of cars (including my Porsche 944 Turbo) unnecessarily bugger the airflow around the nose by marginal installation of fog lights, too many inlets in the grill, etc.. At some point, I may start from scratch with a new nose cone, with one elliptical inlet, etc..

NACA tech papers can be found online, but I don't have a link. Radiused outlet geometry is key to gathering and venting the used cooling air back into the slipstream with minimal drag. The air molecules communicate with each other all along the stream. That sounds nuts, and may be, but it's true. So, downstream molecules influence upstream ones, which then wander off the path. Cooling needs to be holistic, i.e., input, throughput, and output all smoothly mated and compatible. Efficient outlet design may be more critical than inlet, since a good outlet will draw air into and through the cooling system, whereas a good inlet can get the cooling air to the radiator, but then the air may be jammed for lack of proper outlet, so stop flowing well. This is certainly the case with my Porsche intercooler, which has a superb inlet diffuser duct to the heat exchanger, but then leaves the spent air trying to find its way back to the slipstream somehow. I may install a cowl flap.

Heat rises, so vents along the sides of the hood about half way back may be pretty efficient, inducing Venturi suction of hot air from the engine compartment.

FWIW, in the P-51, the belly cooler was pretty efficient, and actually gave the plane a bit of thrust as heated air rejoined the slipstream. |

|

|

|

03-30-2008, 05:38 PM

03-30-2008, 05:38 PM

|

#27 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

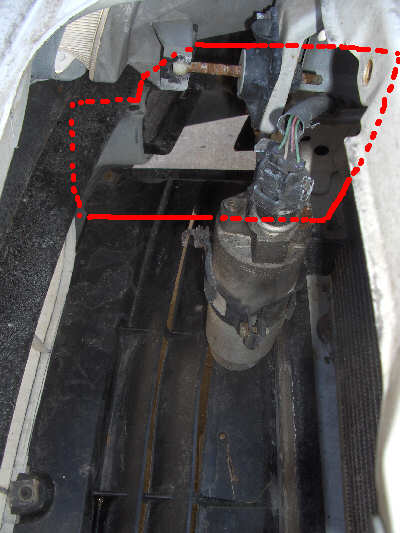

Well, it got above 40°F today, so I was out working on the Paseo. I took a lookg between the bumper and the deflectors I had initially planned on making are going to be a bit tougher than originally thought. The contours inside the bumper cover are not exactly easy to replicate. There is also no way to mount the deflectors. Here is why. The red line indicates where the deflector would go. On both sides there are a few obstructions.

So, I'm going to need to think about how I'm going to do those some more.

In the mean time. I did something else that'll also help. I took some of our favorite piping insulation and stuffed it all around the radiator so as to create a seal around it. Now, very little air should be able to go around the radiator instead of through it. This should reduce the amount of air needed to pass through the grill, and allow me to close more of it off. Here are the pics.

Before. Its hard to see, but theres roughly a .25 - .5 inch gap between the radiator and the support member.

After.

Before.

After.

Before.

After.

This is by no means a replacement for the deflectors. As you can see in the 2nd to last picture there is a big opening where the headlight is (look in the lower right). The deflector would go between the radiator and headlight opening so air can't just go through that hole. However, its a start. It'll be interesting to see if this has any effect on the coolant temperature.

Speaking of coolant temperature, I picked up my 192°F thermostat (180°F is stock) this Saturday when I was out and about for emissions testing. I'll have to get that in, but I would like to see what this does to the setup as it currently is. |

|

|

|

03-30-2008, 09:39 PM

03-30-2008, 09:39 PM

|

#28 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,988 Times in 3,618 Posts

|

I like your thinking on this one - optimizing the flow through the radiator means you can have the most effectively sized block ahead of it. Thumbs up.

|

|

|

|

03-31-2008, 10:02 AM

03-31-2008, 10:02 AM

|

#29 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Yep, thats the idea. Autospeed did an article on this a while back about doing the same thing, but they did it to an intercooler. It dropped intake temps a few degrees.

I have to say, the more I look at it, the more work it seems needs to be done. If anyone has any ideas that could simplify this I'd be all ears.  |

|

|

|

04-21-2008, 08:50 AM

04-21-2008, 08:50 AM

|

#30 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,589 Times in 1,555 Posts

|

Its been about a week now, but I do have the 192°F thermostat in. It appears that the original thermostat was not a problem as the scangauge now shows that my coolant temp is 12°F higher than it was before (original thermostat was 180). The scangauge now shows my coolant temp around 211-213, yet the radiator fan doesn't kick in (its supposed to kick on at 201), so I know something is messed up. It looks like the coolant temp sensor may be shot. Luckily this isn't a very expensive part either.

On top of figuring that out, another problem has arisen. I've had a small exhaust leak near the back of the car for a while now where it goes up and over the rear axle. I just haven't had the time until last week to fix it. So, I got it all welded back up and this quieted down the car. However, I can now hear another problem! The front brakes are dragging a fair amount. So, add that to the checklist of things to do.

Its good to know something can be fixed and my mileage will increase, but its bad to know theres more maintenance to do.

|

|

|

|

|