01-08-2018, 11:37 AM

01-08-2018, 11:37 AM

|

#111 (permalink)

|

|

Master Novice

Join Date: Jan 2008

Location: SE USA - East Tennessee

Posts: 2,314

Thanks: 427

Thanked 616 Times in 450 Posts

|

Quote:

Originally Posted by Phoenix'97

Well, I am interested enough to see if I can help in their research by involving my car. Right now I can't purchase their unit but I can nudge them on the suggestion and see if I can get their minds to contemplate how to make such a system work on my sports car to allow for my gasoline motor to help charge this system while turning the rear wheels and this hybrid system turning the front wheels.

|

Link to MTSU's Green Energy Management page, including an update on the Hybrid Kit concept:

Green Energy Management (GEM) Updates | Middle Tennessee State University

I wouldn't do the alternator thing. This is just me talking, but the quickest way to get maximum uptake from buyers is to make the system as no-brainer easy as possible. I wouldn't balk at switching in alternators but a lot of people might - and the big thing with motors is in order to get any kind of speed out of them, you need voltage. The alternator in your car is NOT designed to provide that. The motors on the wheels, however, ARE already designed for high voltage, and with a simple flip of a switch a motor can become a generator - and in the case of these motors, they'll make way better generators than the alt in your car. So: when the battery needs recharging, simply pull a vanishingly small amount of current out of the motor/generators as they are pulled down the road. The motor management computer can be programmed to hold off such operations until the TPS is below a certain threshhold, when the taillights are on (lots more under those conditions), when the car is pointed downhill, etc. Not too difficult to find plenty of situations where the battery recharging can be done for a minimum of fuel burn.

__________________

Lead or follow. Either is fine.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-08-2018, 11:48 AM

01-08-2018, 11:48 AM

|

#112 (permalink)

|

|

EcoModding Lurker

Join Date: Nov 2014

Location: NY

Posts: 98

Thanks: 15

Thanked 5 Times in 5 Posts

|

Quote:

Originally Posted by elhigh

Link to MTSU's Green Energy Management page, including an update on the Hybrid Kit concept:

Green Energy Management (GEM) Updates | Middle Tennessee State University

I wouldn't do the alternator thing. This is just me talking, but the quickest way to get maximum uptake from buyers is to make the system as no-brainer easy as possible. I wouldn't balk at switching in alternators but a lot of people might - and the big thing with motors is in order to get any kind of speed out of them, you need voltage. The alternator in your car is NOT designed to provide that. The motors on the wheels, however, ARE already designed for high voltage, and with a simple flip of a switch a motor can become a generator - and in the case of these motors, they'll make way better generators than the alt in your car. So: when the battery needs recharging, simply pull a vanishingly small amount of current out of the motor/generators as they are pulled down the road. The motor management computer can be programmed to hold off such operations until the TPS is below a certain threshhold, when the taillights are on (lots more under those conditions), when the car is pointed downhill, etc. Not too difficult to find plenty of situations where the battery recharging can be done for a minimum of fuel burn. |

I see what you are saying. Well, couldn't we also hook up the drive wheels powered by the gasoline motor to electric motors serving as generators only? This way, if I understand you correctly, we can reduce parasitic drain by the engine mounted alternator and replace it with generators running off the drive wheels powered by the same gasoline engine, and for braking or decelerated fuel cut-off, the electric motors on the non-drive wheels can contribute to power generation.

The point I am trying to make is that I would prefer not to have to charge up this system. I want for it to be able to charge itself and the only way to do this is by using the gasoline engine to help charge it up! Even better would be to have the ability to operate all four wheel mounted electric motor/generators in tandem with the gasoline engine, making it work even less and possibly using solar panel films on the upper portion of the car to help recharge the system as well! |

|

|

|

01-08-2018, 11:58 AM

01-08-2018, 11:58 AM

|

#113 (permalink)

|

|

Master EcoModder

Join Date: Dec 2011

Location: New Zealand

Posts: 5,117

Thanks: 2,918

Thanked 2,587 Times in 1,607 Posts

|

Yes, you can absolutely do that, and that's the arrangement almost every hybrid on the market uses. It's trivial at that point to give them a bit of assist too.

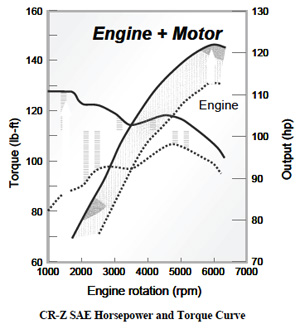

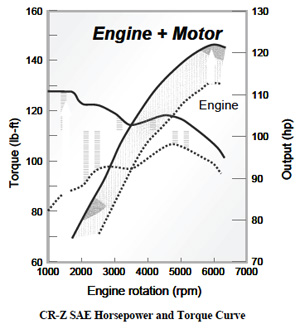

EDIT: Another neat feature of electric motors is that they produce peak torque at effectively 0RPM, where the gasoline engine produces the least. Off-the-line acceleration can be improved dramatically, even if the motor's total output is far less than the gas engine's peak output. Here's the torque curve of a 111HP gasoline engine paired with a 14HP electric motor:

At 1000rpm the electric motor is increasing total torque by almost 60%, despite being only 14HP.

Last edited by Ecky; 01-08-2018 at 12:30 PM..

|

|

|

|

01-08-2018, 12:36 PM

01-08-2018, 12:36 PM

|

#114 (permalink)

|

|

EcoModding Lurker

Join Date: Nov 2014

Location: NY

Posts: 98

Thanks: 15

Thanked 5 Times in 5 Posts

|

Quote:

Originally Posted by Ecky

Yes, you can absolutely do that, and that's the arrangement almost every hybrid on the market uses.

EDIT: Another neat feature of electric motors is that they produce peak torque at effectively 0RPM, where the gasoline engine produces the least. Off-the-line acceleration can be improved dramatically, even if the motor's total output is far less than the gas engine's peak output. Here's the torque curve of a 111HP gasoline engine paired with a 14HP electric motor:

At 1000rpm the electric motor is increasing total torque by almost 60%, despite being only 14HP. |

Well, what comes to mind is an episode of the proper Top Gear, the original British version where Clarkson drives a hybrid hypercar McLaren P1. This is where he mentioned how the electric motor filled in performance gaps of the gasoline engine to result in some insanely impressive performance!

Suffice it to say, I would love to have this kind of complimentary performance in my car. I didn't think it was possible to have access to hybrid technology that I could incorporate with some degree of ease on my V8 car. What this technology would also do for me is make it totally unnecessary to have to build the motor for increased torque production on the low RPM side when the electric motors can help me achieve this!

This is really the best way to have my cake and eat it too! The fuel savings will add up, especially when using Iso-Butanol, and furthermore I can feel great in knowing that I can drive my V8 around town and my emissions are further reduced by hybrid technology. If we can make use of that new solar panel film material on cars, this would also help make the technology even more beneficial when you now don't need to have to plug in these cars for a recharge!

I just hope I will be able to get a kit on my car in the future at some point.

|

|

|

|

01-08-2018, 12:51 PM

01-08-2018, 12:51 PM

|

#115 (permalink)

|

|

Master EcoModder

Join Date: Dec 2011

Location: New Zealand

Posts: 5,117

Thanks: 2,918

Thanked 2,587 Times in 1,607 Posts

|

Right, I think we're on the same page now. The question is, what method will you use to implement it?

I make hybrid bicycles all the time. The controllers can be found for as little as $20 on eBay, can support several thousand watts, and allow for both regenerative braking and acceleration. I bet you could find an inexpensive controller for use in your car, though not $20 cheap. There are some threads floating around in the EV section on this site for DIY controllers, maybe that would be a good place to start? You can attach virtually any controller to virtually any motor.

Regarding the motor, probably the easiest and cheapest is a belt-mounted hybrid motor/generator - it can go in place of the alternator, bolted to the engine, with a beefier belt. Other options are motors attached in-line with the driveshaft (requires custom driveshaft, but has advantages), or hub motors in the wheels (more unsprung weight, but has its own advantages). The motor in most simple hybrids is bolted to the engine. You could even pick your own motor (pull one from a dead forklift?) and fabricate your own mounts and belt pulley for it.

|

|

|

|

01-08-2018, 01:01 PM

01-08-2018, 01:01 PM

|

#116 (permalink)

|

|

Master EcoModder

Join Date: Dec 2011

Location: New Zealand

Posts: 5,117

Thanks: 2,918

Thanked 2,587 Times in 1,607 Posts

|

Come to think of it, I'm sure there are bolt-on supercharger kits for your motor. You can probably just grab a pulley for one of those, and put the electric motor in the same place the blower would usually be. Then, run some low gauge wires from it to a battery + controller in the trunk, or wherever else you decide to stash it.

|

|

|

|

01-08-2018, 02:32 PM

01-08-2018, 02:32 PM

|

#117 (permalink)

|

|

EcoModding Lurker

Join Date: Nov 2014

Location: NY

Posts: 98

Thanks: 15

Thanked 5 Times in 5 Posts

|

Quote:

Originally Posted by Ecky

Right, I think we're on the same page now. The question is, what method will you use to implement it?

Regarding the motor, probably the easiest and cheapest is a belt-mounted hybrid motor/generator - it can go in place of the alternator, bolted to the engine, with a beefier belt. Other options are motors attached in-line with the driveshaft (requires custom driveshaft, but has advantages), or hub motors in the wheels (more unsprung weight, but has its own advantages). The motor in most simple hybrids is bolted to the engine. You could even pick your own motor (pull one from a dead forklift?) and fabricate your own mounts and belt pulley for it.

|

If I can go this route, I am thinking that hub motors would be the way to go. Trying to keep it simple, rear wheel motors do the charging and the front wheels do the pulling, while simultaneously the engine spins the rear wheels for the pushing. Then this way the front hub motors are always in use, even on the expressway and there is no issue of losing too much power when the system has a means to recharge itself. |

|

|

|

01-08-2018, 02:43 PM

01-08-2018, 02:43 PM

|

#118 (permalink)

|

|

Master EcoModder

Join Date: Dec 2011

Location: New Zealand

Posts: 5,117

Thanks: 2,918

Thanked 2,587 Times in 1,607 Posts

|

In my Insight, a common modification is to add a "MIMA" to the stock hybrid system, which is a small joystick most people attach to their shifter which gives manual control over what the motor is doing. Press up to add energy to the battery, press down to add power to the wheels. Tapping it shuts off the engine, left and right run programs (e.g. assist when you press the pedal past a certain point, regen when at low throttle, until the battery is full).

For your retrofit, it's possible to just program the system to do things automatically, or to only have a joystick for manual control, or both. |

|

|

|

|

The Following User Says Thank You to Ecky For This Useful Post:

|

|

01-08-2018, 03:08 PM

01-08-2018, 03:08 PM

|

#119 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,093

Thanks: 8,256

Thanked 9,020 Times in 7,453 Posts

|

Quote:

|

The point I am trying to make is that I would prefer not to have to charge up this system. I want for it to be able to charge itself and the only way to do this is by using the gasoline engine to help charge it up!

|

You could put a propeller on the nose and use it to generate current. That would be even less efficient than burning the gas directly.

Once again — Kinetic Energy Recovery [System].

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

____________________

.

.What the headline giveth, the last paragraph taketh away. -- Scott Ott

|

|

|

|

01-08-2018, 03:18 PM

01-08-2018, 03:18 PM

|

#120 (permalink)

|

|

EcoModding Lurker

Join Date: Nov 2014

Location: NY

Posts: 98

Thanks: 15

Thanked 5 Times in 5 Posts

|

Quote:

Originally Posted by Ecky

In my Insight, a common modification is to add a "MIMA" to the stock hybrid system, which is a small joystick most people attach to their shifter which gives manual control over what the motor is doing. Press up to add energy to the battery, press down to add power to the wheels. Tapping it shuts off the engine, left and right run programs (e.g. assist when you press the pedal past a certain point, regen when at low throttle, until the battery is full).

For your retrofit, it's possible to just program the system to do things automatically, or to only have a joystick for manual control, or both.

|

Well, now a simple concept becomes more complicated. Why would I even want to have that integrated into my console by the shifter? Either the system works without my input or it doesn't.

Quote:

Originally Posted by freebeard

You could put a propeller on the nose and use it to generate current. That would be even less efficient than burning the gas directly.

Once again — Kinetic Energy Recovery [System].

|

Is this thread now turning into a joke? I hope not.

|

|

|

|

|