08-17-2014, 08:51 PM

08-17-2014, 08:51 PM

|

#921 (permalink)

|

|

Permanent Apprentice

Join Date: Jul 2010

Location: norcal oosae

Posts: 523

Thanks: 351

Thanked 318 Times in 215 Posts

|

Sounds a bit like the boost converters used for chargers.... hmmm.... how about giving this thing the dual job of boosting the voltage to the motor and charging the batteries...  I could really see the value of one in this case.

The other charger-type technology I'm trying to wrap my head around is AC Propulsion's use of part of the AC inverter as the charger. I've kind of got it for induction motors, but I'm not sure about BLDC... Ideas??

- E*clipse

Quote:

Originally Posted by MPaulHolmes

Have the low side be the low side switch in the boost converter. The inductor connects to the collector of the low side switch. Now, the high side IGBT has the diode built in from high side emitter to high side collector. That's the regular diode in the boost converter. The high side switch is what allows the regen to go to the batteries. During regen, low side IGBT off, and high side IGBT on with 100% duty.

|

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

08-17-2014, 09:42 PM

08-17-2014, 09:42 PM

|

#922 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,311

Thanks: 8,336

Thanked 9,095 Times in 7,512 Posts

|

Quote:

|

Ummm, regarding dimensions, as you can see from the pic, they're pretty oddly shaped. What dimensions would you like?

|

Anything, really. The proportions appear to be 1 motor diameter wide and high, and 2 diameters long. It looks like the ring gear is more compact with the teeth on the face rather than the flank, like most diffs. For comparison, here's a Subaru transaxle on the VW Type I frame.

There're about 10" between the forks, and I have no problem with moving the axles to behind the crossmember (using off-road racer 3x3 trailing arms).

I guess there are temperature sensors built in. Are the spider gears hidden inside that ring gear in the differential?

TIA

|

|

|

|

08-18-2014, 12:17 AM

08-18-2014, 12:17 AM

|

#923 (permalink)

|

|

Master EcoModder

Join Date: Sep 2010

Location: Saskatoon, canada

Posts: 1,488

Thanks: 746

Thanked 565 Times in 447 Posts

|

Quote:

Originally Posted by MPaulHolmes

Have the low side be the low side switch in the boost converter. The inductor connects to the collector of the low side switch. Now, the high side IGBT has the diode built in from high side emitter to high side collector. That's the regular diode in the boost converter. The high side switch is what allows the regen to go to the batteries. During regen, low side IGBT off, and high side IGBT on with 100% duty.

|

I attached a captured image from the AEVA discussion.

The low side is D, high side is U. During regen, D is off, and U is On, as you describe above, right?

Would that put a large over-voltage on the battery terminals? Or would the voltage 'drop' across the IGBT with the large currents involved? Or did I hijack the wrong diagram? |

|

|

|

08-18-2014, 12:28 AM

08-18-2014, 12:28 AM

|

#924 (permalink)

|

|

Master EcoModder

Join Date: Sep 2010

Location: Saskatoon, canada

Posts: 1,488

Thanks: 746

Thanked 565 Times in 447 Posts

|

Quote:

Originally Posted by e*clipse

Sounds a bit like the boost converters used for chargers.... hmmm.... how about giving this thing the dual job of boosting the voltage to the motor and charging the batteries...  I could really see the value of one in this case. |

I believe that Ryan at Netgain Controls tried for an all-in-one design, not quite this combination of features ...:

- DC/DC converter

- DC Controller

- Buck/boost battery charger

He started out using the field coil of the series DC motor as the inductor (which is a BIG inductor that you are already carrying) for the battery charger. The DC controller has an isolated DC power supply for his electronics anyway, so he added another for the DC/DC converter, to run the 12V car stuff, and added his regular netgain industrial DC controller (with some upgrades, of course) to the mix.

That was the general idea of the product announcement at EVCCON 2012 but I have not seen the product available, even as beta or alpha. I expect that he ran into some sort of implementation issues.

Back to your question - if the boost controller is part of the input stage for the controller (which is where the batteries are connected) I don't see how the batteries could also be attached to the output of the boost controller ... so what did I miss this time, Paul? |

|

|

|

08-18-2014, 12:52 AM

08-18-2014, 12:52 AM

|

#925 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

Yes, that's what I was trying to say (the picture). The throttle ideally is a wig wag. In the DC case, throttle is proportional to current. In the AC case throttle is proportional to Iq, which is still basically the motor's torque. But in the AC case with field oriented control, you do regen just by commanding a negative Iq. The PI loop makes the current follow throttle position. Even though the battery voltage is maybe only half, the current won't be large because the the Iq current would have very quickly converged to the throttle position due to the PI loop.

Not batteries connected to the output of the boost converter. Rather, the boost converter sort of bypassed backwards, so the current just goes right through U, thru the inductor, and to the batteries.

Edit: negative Iq just means negative torque, so slowing down. Care would have to be taken to ensure that the negative Iq didn't result in too big of a current to the batteries. But with a simple current feedback for the battery pack, you would be able to just limit commanded negative torque. Like when you limit limit battery amps in the dc case.

Actually, you wouldn't need a battery current sensor I don't think. In the DC case, to limit battery amps, you use the relationship

ampsBatt = PWM_DUTY * ampsMotor. So, when you monitor ampsMotor, and you know PWM_DUTY, you can just know ampsBatt. I think it would be analogous in the AC case. Instead of ampsMotor, it would be Iq (the current that is rotating, but "fixed" in magnitude, and is responsible for the torque).

I was just noticing that the 3 high side controllers that the beta testers are using right now could be used as boost converters just by adding an inductor to the 3 M+ cables. Then, the other side of the inductor would connect to the low voltage battery bank B+. Then, the normal B+ and B- on the DC controller would connect to B+ and B- of the AC controller. Then, if you had a 1000amp inductor (haha), you could have a 200kw boost converter, or so.

Last edited by MPaulHolmes; 08-18-2014 at 01:31 PM..

|

|

|

|

|

The Following User Says Thank You to MPaulHolmes For This Useful Post:

|

|

08-18-2014, 01:25 AM

08-18-2014, 01:25 AM

|

#926 (permalink)

|

|

Permanent Apprentice

Join Date: Jul 2010

Location: norcal oosae

Posts: 523

Thanks: 351

Thanked 318 Times in 215 Posts

|

Hi Freebeard!

Ok, these are really rough dimensions; please don't do any real engineering based on them. If you get that close, I'd be happy to get accurate numbers...

Output flange to output flange: 10.7" (272mm)

Rear mounting flange to output axle centerline: 100mm

Axle centerline to front bolt hole Centerline: 305mm

Approximate motor outer diameter: 13"

Approximate overall length: 17"

dry weight (bathroom scale) 90.2 lbs

Yes, the spider gears are in the differential. It's a standard open differential. Also, the temp sensors are built into the stator.

It looks like the flange-to-flange length is close enough for a single MGR adaptation to work directly. However, that's only 50kW. Also, it looks (from the Scooby adaptation picture) that it may need to be mounted in reverse, requiring an external oil cooler/pump.

- E*clipse

Quote:

Originally Posted by freebeard

Anything, really. The proportions appear to be 1 motor diameter wide and high, and 2 diameters long. It looks like the ring gear is more compact with the teeth on the face rather than the flank, like most diffs. For comparison, here's a Subaru transaxle on the VW Type I frame.

There're about 10" between the forks, and I have no problem with moving the axles to behind the crossmember (using off-road racer 3x3 trailing arms).

I guess there are temperature sensors built in. Are the spider gears hidden inside that ring gear in the differential?

TIA |

Last edited by e*clipse; 08-18-2014 at 01:31 AM..

Reason: more info

|

|

|

|

|

The Following User Says Thank You to e*clipse For This Useful Post:

|

|

08-18-2014, 03:43 AM

08-18-2014, 03:43 AM

|

#927 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,311

Thanks: 8,336

Thanked 9,095 Times in 7,512 Posts

|

Thanks

My application is a Baja Bug that will be lighened and boat-tailed. The ICE was 36hp so I think one MGR will suffice. Rather than mount in reverse, I'd put the motor's shaft about where the Subaru axle centerline is with the new centerline behind the crossmember. Unless the external pump is mandatory—then why not. That would fit under the stock rear sheetmetal.

I'm going to talk to the shop I work with in the morning. Maybe get two, use the best one and keep the other in reserve in case the supply dries up. What is the preferred nomenclature or part number to search for to find them online?

|

|

|

|

08-18-2014, 01:48 PM

08-18-2014, 01:48 PM

|

#928 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

OK, so you don't turn off the boost converter ever. The high side IGBT is the complement of the low side. Still switch it even when regen isn't happening. It serves no purpose during those times, but whatever. Then regen will still work, and the boost converter acts like a buck converter.

|

|

|

|

|

The Following User Says Thank You to MPaulHolmes For This Useful Post:

|

|

08-19-2014, 04:26 PM

08-19-2014, 04:26 PM

|

#929 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

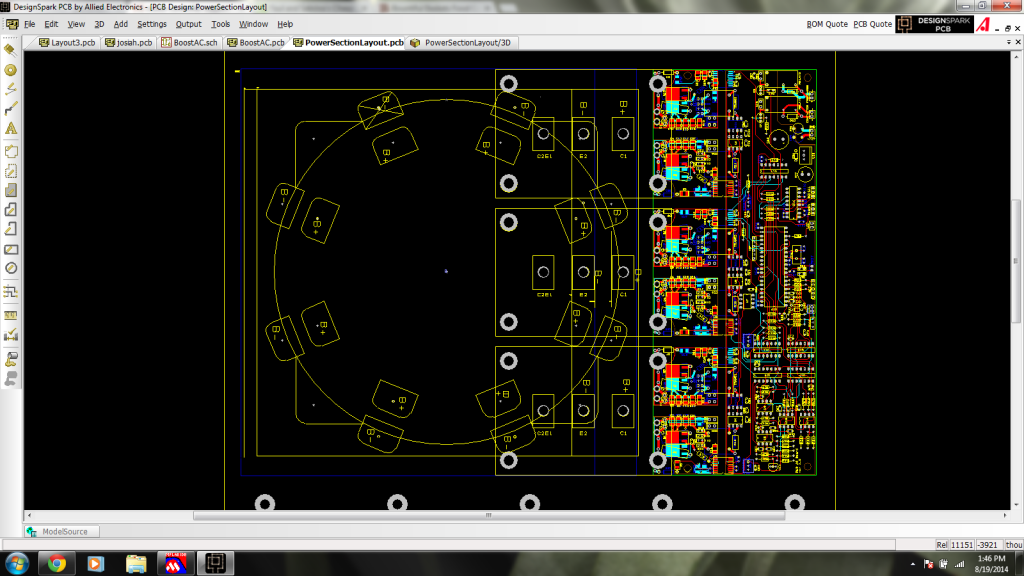

Actually, I think I'll try this. You can fuse the output cap of the boost converter and input cap of the AC controller into 1. So, the layout works out in an incredibly clean way. Instead of 3 IGBTs plugged into the control/driver board (like on the regular old AC controller), and also bolted to the ring capacitor, you have 4 plugged into the (not yet existing) control/driver board. And bolt all 4 igbts in exactly the same way to the ring capacitor. Then, instead of 3 cables heading out (for U, V, W), you have 4 cables. 3 go to the AC motor, and one goes to an inductor. The other side of the inductor goes to the battery pack +. Done! I was thinking of a separate little box for the inductor. The 1200v 600amp IGBTs have the same footprint and dimensions as the 600v 600amp IGBTs, so you could boost 300v at 200amp to 600v at 100amp with a stock $340 inductor.

So, instead of the following picture, you would have 4 IGBTs. You would have to switch out the dsPIC30F4011 for the dsPIC30F6015, which has PWM1L, PWM1H, ..., PWM4L, PWM4H. Use pwm4l and pwm4h for controlling the 4th IGBT's pwm:

Last edited by MPaulHolmes; 08-19-2014 at 05:04 PM..

|

|

|

|

08-19-2014, 09:49 PM

08-19-2014, 09:49 PM

|

#930 (permalink)

|

|

Dreamer

Join Date: Nov 2013

Location: Australia

Posts: 350

Thanks: 95

Thanked 214 Times in 151 Posts

|

Quote:

Originally Posted by MPaulHolmes

Actually, I think I'll try this. You can fuse the output cap of the boost converter and input cap of the AC controller into 1. So, the layout works out in an incredibly clean way. Instead of 3 IGBTs plugged into the control/driver board (like on the regular old AC controller), and also bolted to the ring capacitor, you have 4 plugged into the (not yet existing) control/driver board. And bolt all 4 igbts in exactly the same way to the ring capacitor. Then, instead of 3 cables heading out (for U, V, W), you have 4 cables. 3 go to the AC motor, and one goes to an inductor.

|

So it will be a redesign / expansion of the power section and some changes to the control section for the different processor and additional PWM output circuit.

Would that mean the same redesigned board could be used by the DC guys to have 4 IGBTs rather than 3? More power.

They probably wouldn't need so many isolated power supplies but maybe the extra component cost wouldn't be so much and you could have a standardised board for both DC and AC? Or maybe the layout could be made so that it was easy to use a single power supply for all drivers or populate out all components and have isolated supplies for each driver?

Would be neat to have a single PCB design that could be AC with boost, AC without boost, DC with 4 IGBTs or DC with 3 IGBTs and boost.

|

|

|

|

|

The Following 3 Users Say Thank You to Astro For This Useful Post:

|

|

|