08-27-2012, 03:07 AM

08-27-2012, 03:07 AM

|

#1 (permalink)

|

|

EcoModding Apprentice

Join Date: Dec 2011

Location: Minnesota

Posts: 201

Thanks: 45

Thanked 8 Times in 7 Posts

|

Permanent cyl deactivation

I'm sure it's been discussed here or something but, are there any downsides to simply flat out disabling a few cylinders on an engine other than maybe roughness or something? Like could I turn a V8 into a 4cyl by just putting metal shims or something to block the intake and exhaust, or possibly pulling the lifters out so the valves never activate, or both... Or even down to 2cyl, or taking a factory 4cyl down to 1cyl. For that matter what if a person removes entire con rods/pistons from an engine so there's no friction, maybe just replacing it with a slug of similar weight on the crank so it doesn't imbalance while spinning??

Why do normal 'variable displacement' systems have to deactivate the valve mechanically, why not just some kind of butterflies in the intake or something? (or/and the exhaust but I don't see how that would affect anything even left unblocked)

This is really open ended, i'm hoping someone whose researched/tried it more might be able to bring me up to speed. The use would not just be for automotive - going to 1/4 the cyl originally designed is so little displacement you'd rightfully ask why not just use a smaller engine - the answer is sometimes junkyard car engines are even cheaper than small engines in a given size, slowing down rpm only goes so far - 've been given engines if I wanted to take them, yet the only application I wanted to use them for - like a small generator of maybe 10hp sustained they would still be grossly oversized for running on all cylinders... such a strategy could actually combine with extended in place engine life postponing rebuild/replacement by switching which cylinder you were firing on too, putting the old piston/con rod back in for one of the other cylinders and moving the crank weight over to the one you wore out. Heck maybe it could be a way to still use engines otherwise damaged - like cracked or scored cylinder walls but you aren't using them all so just disable those so damaged.  That's a good example of engines often available for free.

I eventually want to experiment with temporary deactivation too like the new systems do but before I bother with that I figure better to get a handle on how to permanently do it so see if there are alternatives to just mechanical valve actuation.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

08-27-2012, 10:23 AM

08-27-2012, 10:23 AM

|

#2 (permalink)

|

|

Batman Junior

Join Date: Nov 2007

Location: 1000 Islands, Ontario, Canada

Posts: 22,541

Thanks: 4,085

Thanked 6,989 Times in 3,619 Posts

|

|

|

|

|

|

The Following User Says Thank You to MetroMPG For This Useful Post:

|

|

08-27-2012, 01:57 PM

08-27-2012, 01:57 PM

|

#3 (permalink)

|

|

Master EcoModder

Join Date: Dec 2008

Location: Southern WI

Posts: 829

Thanks: 101

Thanked 563 Times in 191 Posts

|

Quote:

Originally Posted by stillsearching

....Why do normal 'variable displacement' systems have to deactivate the valve mechanically, why not just some kind of butterflies in the intake or something? (or/and the exhaust but I don't see how that would affect anything even left unblocked....

|

Hi,

If you are going to deactivate cylinders, then simply pull the rockers from that cylinder, and make sure you do this both the intake and exhaust.

Why the exhaust too?

Because, anytime you start moving air around, there is a local loss of energy. With the exhaust valve opening, there is more airflow through the exhaust port and back again when the piston moves back down.

With both valves left in the closed position, air is repeatedly compressed, but at least there is no airflow, and compressing the cylinder results in some energy back into the system when that piston drops to BDC again.

Jim. |

|

|

|

08-27-2012, 04:04 PM

08-27-2012, 04:04 PM

|

#4 (permalink)

|

|

Wiki Mod

Join Date: Nov 2009

Location: Midland MI, USA

Posts: 2,042

Thanks: 228

Thanked 304 Times in 210 Posts

|

I have thought of doing this before but never done it.

I am no engine engineer so help me with this, what if I killed the fuel injectors to 2 of the 4 cylinders and left the valves in place? Say start with all 4 on then kill switch off a pair (say 2&4 or 1&3 in firing order). What if any issues would this cause? I can see my dash with a row of master kill switches (think aircraft panel with nice lights under them to indicate on or off)

__________________

|

|

|

|

08-27-2012, 07:18 PM

08-27-2012, 07:18 PM

|

#5 (permalink)

|

|

Master Ecomadman

Join Date: Nov 2010

Location: Chicago area

Posts: 1,157

Thanks: 20

Thanked 337 Times in 227 Posts

|

Been there done that. 2 cyl is not enough power for everyday driving.

Cutting just the injectors will put air onto the exhaust and the engine control will respond by richening the mixture or going to open loop.

__________________

- Tony

|

|

|

|

08-27-2012, 09:10 PM

08-27-2012, 09:10 PM

|

#6 (permalink)

|

|

Wiki Mod

Join Date: Nov 2009

Location: Midland MI, USA

Posts: 2,042

Thanks: 228

Thanked 304 Times in 210 Posts

|

is air in the exhaust a bad thing? can I spoof the ECU to keep it in the right fuel range?

__________________

|

|

|

|

08-28-2012, 12:05 PM

08-28-2012, 12:05 PM

|

#7 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 710 Times in 458 Posts

|

Quote:

Originally Posted by Weather Spotter

is air in the exhaust a bad thing? can I spoof the ECU to keep it in the right fuel range?

|

Air in the exhaust, affecting the O2 sensor reading, is an important concern and is also beside the point.

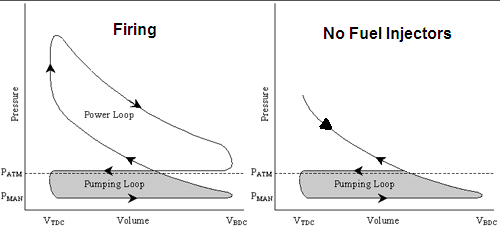

For an engine for which the non-firing cylinders' valves are allowed to open and close as before, the above graph shows how much useful work is generated by each firing cylinder, which is represented by the white area inside the curve. This is after heat losses to the exhaust and to the coolant are considered. The graph also shows how much suction work is needed by all firing and non-firing cylinders. That's the gray area.

Note that the non-firing cylinders still require suction work.

In this hypothetical engine, the work produced by each firing cylinder now has to cover the suction work needed by two cylinders - one firing, and one non-firing. This is in addition to the work needed to overcome friction losses, drivetrain losses, aerodynamic losses, and to propel the vehicle down the road.

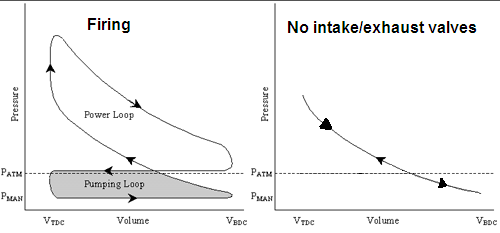

Now, in this graph, the non-firing cylinders also have their valves deactivated. Note that the non-firing cylinders do not require work in the sense that they did when just the fuel injectors were shut off. Now, the firing cylinders just have to provide suction work for themselves, in addition to the friction and drivetrain and aerodynamic losses, and to propel the vehicle down the road.

|

|

|

|

|

The Following User Says Thank You to t vago For This Useful Post:

|

|

08-28-2012, 05:22 PM

08-28-2012, 05:22 PM

|

#8 (permalink)

|

|

Wiki Mod

Join Date: Nov 2009

Location: Midland MI, USA

Posts: 2,042

Thanks: 228

Thanked 304 Times in 210 Posts

|

so all that comes down to, without closing the valves its not worth it, the pumping losses will negate most (all) of the gas savings.

Bummer!

__________________

|

|

|

|

08-28-2012, 06:01 PM

08-28-2012, 06:01 PM

|

#9 (permalink)

|

|

MPGuino Supporter

Join Date: Oct 2010

Location: Hungary

Posts: 1,808

iNXS - '10 Opel Zafira 111 Anniversary Suzi - '02 Suzuki Swift GL

Thanks: 831

Thanked 710 Times in 458 Posts

|

More or less. And, using a butterfly valve on selected intake runners, in order to shut off those cylinders, would be even worse than merely shutting down the injectors for those cylinders. I started work on a similar project for my truck, shortly after joining this board, only to come to the realization that this butterfly valve idea would not work as intended.

|

|

|

|

08-29-2012, 08:58 AM

08-29-2012, 08:58 AM

|

#10 (permalink)

|

|

Master Ecomadman

Join Date: Nov 2010

Location: Chicago area

Posts: 1,157

Thanks: 20

Thanked 337 Times in 227 Posts

|

He is not taking into account the lower manifold vacuum due to the 2 active cylinders working harder to keep up, the engine would be at full throttle twice as long with half the cylinders. I would go as far to say that under load it would have half the manifold vacuum and thus half the pumping loss. Of course if the valves were deactivated then it would have half the vacuum and half the displacement for 1/4 the pumping loss of a full engine.

Quote:

Originally Posted by Weather Spotter

so all that comes down to, without closing the valves its not worth it, the pumping losses will negate most (all) of the gas savings.

Bummer!

|

__________________

- Tony

|

|

|

|

|