08-10-2015, 09:11 AM

08-10-2015, 09:11 AM

|

#291 (permalink)

|

|

Uber Geek

Join Date: Sep 2014

Location: Ann Arbor, MI

Posts: 95

Mr. Scary - '07 Ford Mustang GT Race Car The Truck - '12 Ford F-150 Scab EcoBoost FX4 The 5.0 - '12 Ford Mustang GT Vert Brembo Premium Da Foci - '14 Ford Focus SE

Thanks: 10

Thanked 52 Times in 31 Posts

|

Quote:

Originally Posted by RobertISaar

air temp sensors can be quite laggy in comparison to actual air temp rise.... their thermal mass just takes too long to match the temp of the incoming air to be accurate unless held in similar conditions for fairly long periods of time, something like 60 seconds may be necessary get 90% of the delta for some sensors. I wouldn't be surprised if that were happening here if measured temps only rise that much.

|

Great point^^^^^

I forgot he is probably using a "blow through" MAF with the IAT sensor built in (a guess). Those are very slow reacting.

I'm used to using the "bulb"/stand alone style sensors (PD blower applications) which are nearly instantaneous. I'm mostly using OEM stuff reading through the OEM ECU. I did have some issue with wonky reading on our 2015 Mustang GT sensor so I put a second/stand along gauge to verify what I was seeing (end up the ECU was wrong). I used this one here:

Prosport Intake air temperature gauge, instant read air temperature gauge.

Inexpensive and almost instantaneous. And as far as I can tell very accurate (I rane a few tests on it). They also have one for turbo cars that has two sensors/readouts so you can do a pre and post IC measurement.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

08-10-2015, 12:29 PM

08-10-2015, 12:29 PM

|

#292 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,560

Thanks: 1,325

Thanked 612 Times in 399 Posts

|

I'm running a GM IAT sensor thats mounted in the charge pipe about 20" before the T/B. I'm running speed density so no MAF. I have check the temps with a infra red gun and they match what the IAT sensor is reading. After the pull that I referenced the IAT read 90*F about 20 seconds later.

On my small 14b turbo I would see around 140*F with the same A2A. On this setup my low pressure turbo runs first through a small A2A then has to travel 9 feet of charge pipe before it reaches the high pressure turbo's inlet. The low pressure turbo is running around 8 psi. on the pump gas tune. The high pressure turbo outlet is 6 feet of charge pipe before A2A, the A2A is 2.5 feet by 2 feet then the outlet form the A2A is 5 feet before the T/B.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

08-10-2015, 12:57 PM

08-10-2015, 12:57 PM

|

#293 (permalink)

|

|

Uber Geek

Join Date: Sep 2014

Location: Ann Arbor, MI

Posts: 95

Mr. Scary - '07 Ford Mustang GT Race Car The Truck - '12 Ford F-150 Scab EcoBoost FX4 The 5.0 - '12 Ford Mustang GT Vert Brembo Premium Da Foci - '14 Ford Focus SE

Thanks: 10

Thanked 52 Times in 31 Posts

|

I've used those GM sensors before, they are fast/accurate.

All of that tubing must really be shedding some heat!!! Pretty cool, pun intended.  |

|

|

|

|

The Following User Says Thank You to sqidd For This Useful Post:

|

|

08-12-2015, 11:16 AM

08-12-2015, 11:16 AM

|

#294 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,560

Thanks: 1,325

Thanked 612 Times in 399 Posts

|

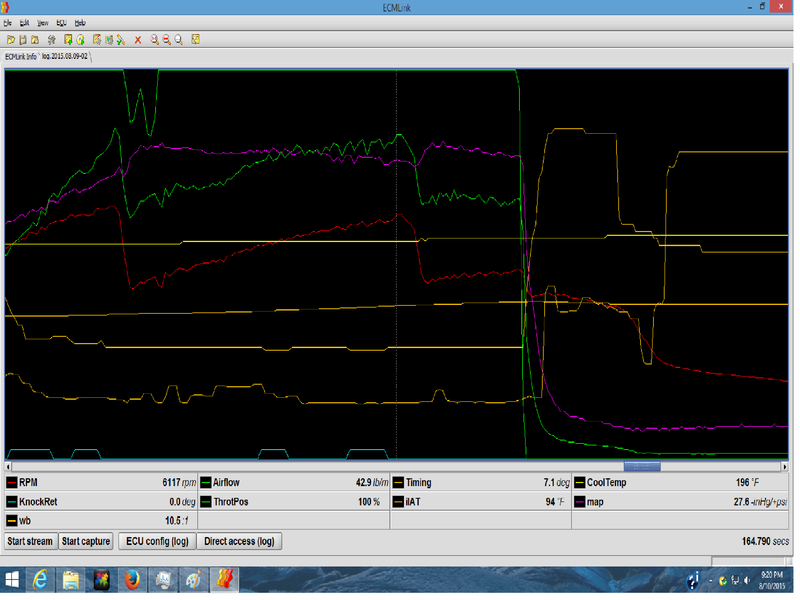

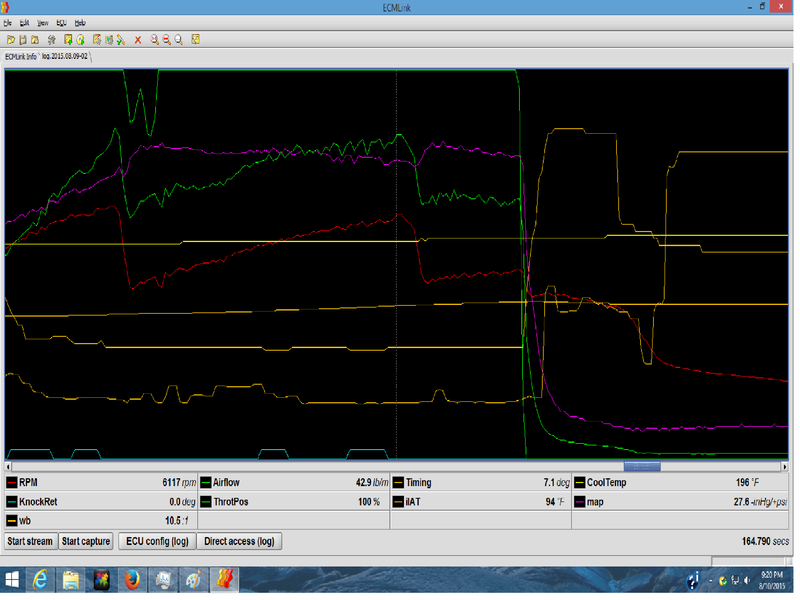

Heres a print screen of my data log that I was referring to.

After doing more testing on race fuel and pump gasoline I'm very happy with the results. It looks like I will be making 500 HP on pump and 650 Hp on race fuel.

Now its time to go back to more FE testing and start the emission test.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

|

The Following User Says Thank You to pgfpro For This Useful Post:

|

|

08-12-2015, 08:10 PM

08-12-2015, 08:10 PM

|

#295 (permalink)

|

|

Uber Geek

Join Date: Sep 2014

Location: Ann Arbor, MI

Posts: 95

Mr. Scary - '07 Ford Mustang GT Race Car The Truck - '12 Ford F-150 Scab EcoBoost FX4 The 5.0 - '12 Ford Mustang GT Vert Brembo Premium Da Foci - '14 Ford Focus SE

Thanks: 10

Thanked 52 Times in 31 Posts

|

Quote:

Originally Posted by pgfpro

Heres a print screen of my data log that I was referring to.

After doing more testing on race fuel and pump gasoline I'm very happy with the results. It looks like I will be making 500 HP on pump and 650 Hp on race fuel.

Now its time to go back to more FE testing and start the emission test. |

That's a whole lotta beans out of a itty bitty 4cyl!

|

|

|

|

|

The Following User Says Thank You to sqidd For This Useful Post:

|

|

08-13-2015, 01:03 AM

08-13-2015, 01:03 AM

|

#296 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,560

Thanks: 1,325

Thanked 612 Times in 399 Posts

|

Quote:

Originally Posted by sqidd

That's a whole lotta beans out of a itty bitty 4cyl!  |

Thanks Man!!!

A few items that I'm very happy with as far as the compound system goes.

#1 The low end torque of my small 13g with out the heat and peak flow numbers suffering. My little 13g turbo by itself would max out around about 26lbs/min. I did some testing with just the 13g turbo and the engine would hit a wall at 24lbs/min and not pull at all. Plus the IAT numbers would increase at a unreal amount and light up the knock sensor. Now I have all the low end torque the 13g provides without any upper air flow limitations up to 65 lbs/min.

#2 Running just the large FP Red turbo my engine had some turbo lag. It would take around 5500 rpm to reach max boost. This made the engine very peaky. Now the FP Red large turbo thinks its hooked to a 310CI engine instead of a 122CI engine at 4000 rpm as a example. So it comes on-line very fast.

#3 Decrease Back Pressure. This is one thing I didn't believe until I seen it with my own eyes. My back pressure is very low for the air flow its running compared to a single match turbo of the same flow. The reason behind this is that the large FP Red turbo is now running at a much lower pressure ratio then if it was a single. I'm running at or under a 2:1 PR with the compound system. Running it as a single I was running it at a 2.5 to 3.0 PR. When you run a high pressure ratio you have to run a higher wheel speed. To run a high wheel speed you have to have a higher drive pressure or exhaust pressure.

#4 This is about the FE side of things that the compound systems is helping with. At 5 to 10 psi around 25 to 35% throttle I'm running at 14.7 to 20:1 A/F.

This has helped when the car is at a dead stop and has to accelerate up to speed. In making this car a dual purpose car. I had to make some sacrifice when it came to engine compression. I wanted a car that could run on pump fuel without any race fuel, and still run in the mid 10's. So to do this I drop the compression down to 7.7:1. I also knew that I could get some of efficiency back at mid to light load with added back pressure when the small turbo is on its own. Plus my goal was to make up for what I lost in static compression and get it back in effective boost compression. Well so far it looks like its working. I need to do a video of this when I'm going from stop light to stop light. The engine sounds like a diesel with the turbos singing.lol I even had a guy in a diesel ask me if I was running a diesel and what turbo I was running because of how loud it was.

Sorry for the long post.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

|

The Following 2 Users Say Thank You to pgfpro For This Useful Post:

|

|

08-14-2015, 04:00 PM

08-14-2015, 04:00 PM

|

#297 (permalink)

|

|

Corporate imperialist

Join Date: Jul 2011

Location: NewMexico (USA)

Posts: 11,312

Thanks: 273

Thanked 3,580 Times in 2,843 Posts

|

Whats the deal with running leaner than 17:1?

When I start to get up near 18:1 I can tell power is dropping off pretty bad.

Is that normal or am I not running enough timing advance?

__________________

1984 chevy suburban, custom made 6.5L diesel turbocharged with a Garrett T76 and Holset HE351VE, 22:1 compression 13psi of intercooled boost.

1989 firebird mostly stock. Aside from the 6-speed manual trans, corvette gen 5 front brakes, 1LE drive shaft, 4th Gen disc brake fbody rear end.

2011 leaf SL, white, portable 240v CHAdeMO, trailer hitch, new batt as of 2014.

|

|

|

|

08-14-2015, 06:54 PM

08-14-2015, 06:54 PM

|

#298 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,560

Thanks: 1,325

Thanked 612 Times in 399 Posts

|

Quote:

Originally Posted by oil pan 4

Whats the deal with running leaner than 17:1?

When I start to get up near 18:1 I can tell power is dropping off pretty bad.

Is that normal or am I not running enough timing advance?

|

On my engine I try to run at least 18:1 and up to 25:1 depending on load. I'm trying to run lean enough to reduce all intake pumping losses. The turbo helps with this verses a N/A engine.

I'm also increasing ignition timing to help out the lean burns slow flame propagation.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

Last edited by pgfpro; 08-14-2015 at 10:05 PM..

|

|

|

|

08-15-2015, 05:26 PM

08-15-2015, 05:26 PM

|

#299 (permalink)

|

|

Corporate imperialist

Join Date: Jul 2011

Location: NewMexico (USA)

Posts: 11,312

Thanks: 273

Thanked 3,580 Times in 2,843 Posts

|

With a carb and GM HEI ignition I don't think there are a lot of options.

Unless I can use the 0-10v or 4-20ma output on my AEM air fuel meter to signal some sort of aftermarket MSD ignition box (which I don't have yet) to further advance the timing.

__________________

1984 chevy suburban, custom made 6.5L diesel turbocharged with a Garrett T76 and Holset HE351VE, 22:1 compression 13psi of intercooled boost.

1989 firebird mostly stock. Aside from the 6-speed manual trans, corvette gen 5 front brakes, 1LE drive shaft, 4th Gen disc brake fbody rear end.

2011 leaf SL, white, portable 240v CHAdeMO, trailer hitch, new batt as of 2014.

|

|

|

|

08-15-2015, 07:58 PM

08-15-2015, 07:58 PM

|

#300 (permalink)

|

|

In Lean Burn Mode

Join Date: Apr 2009

Location: Pacific NW

Posts: 1,560

Thanks: 1,325

Thanked 612 Times in 399 Posts

|

Quote:

Originally Posted by oil pan 4

With a carb and GM HEI ignition I don't think there are a lot of options.

Unless I can use the 0-10v or 4-20ma output on my AEM air fuel meter to signal some sort of aftermarket MSD ignition box (which I don't have yet) to further advance the timing.

|

I agree that would be tough to do with just a carb and HEI ignition.

With my engine management system I can pick out just a group of cells that I lower the fuel injector pulse width and increase ignition timing at based on load and rpm. I also run two different fuel/ignition maps, one for lean burn with waste solvent and one with out waste solvent. The fuel map cross over happens by threshold speed, load, TB angle and rpm. When waste solvent is enable I add the solvent manually with a solvent regulator. This is at freeway speed and the waste solvent is a set mass flow. The main injectors increase or decrease their pulse width based on load and rpm. My waste solvent enable MPH window is 50 mph to 70 mph.

__________________

Pressure Gradient Force

The Positive Side of the Number Line

|

|

|

|

|