Update:

I got myself a movable grill block!

On the car:

Closed:

Open:

I took the easy way out and made a sliding grill block. I compromised and just replaced the grates with the slider. It is still stealth

The OEM grill has an opening of 94 sq". Mine has about 75 sq" or 80% of OEM

I did this by keeping it back and then I can make it taller than the OEM one. It is also wider by 3 ".

How I made it:

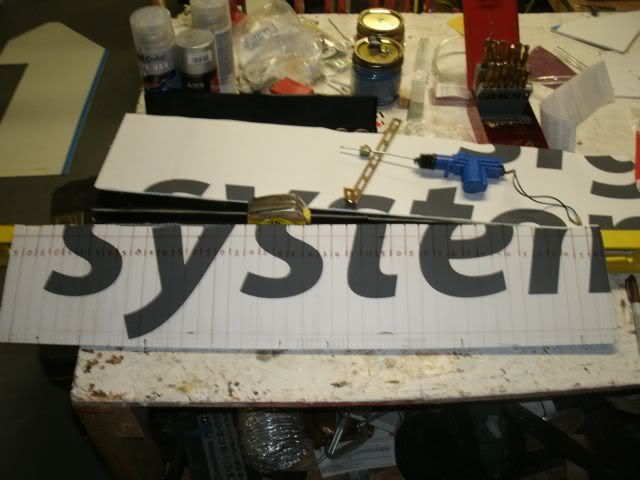

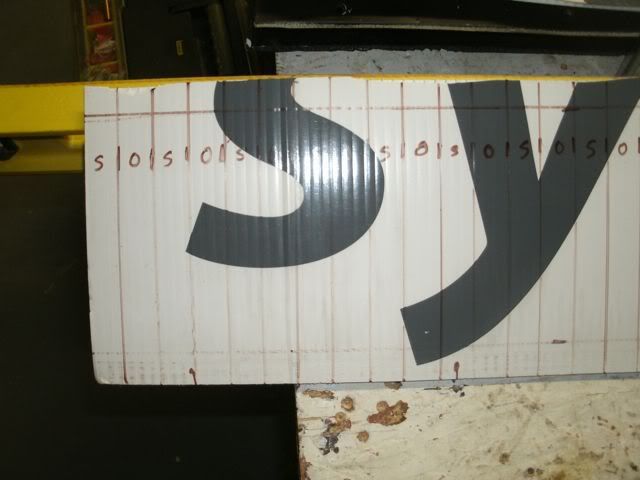

I cut some colorplast to the size I wanted. I measured the actuation length to be .75" so that is how wide I made the slats. I marked them all out before cutting:

One cut out:

and #2:

I cut some slots for bolts and put the bolts in. I saw that I needed spacers on the back side:

Assembled open:

Closed:

Once I put it on I found that I had too much play in the pices (away from each other). So I made some brackets to allow sliding but not in and out from air pressure:

On the car:

I just used the clamps for now, I will likely epoxy in on but for testing and my trip tomorrow this should work. The actuator and mounts are just hot glued onto the colorplast.

I still need to paint it but I can do that after my trip.

What do you think?