03-25-2011, 06:59 PM

03-25-2011, 06:59 PM

|

#121 (permalink)

|

|

Master EcoModder

Join Date: Dec 2007

Location: Norfolk, Va. USA

Posts: 869

Thanks: 14

Thanked 33 Times in 28 Posts

|

Modern disc brakes are designed to completely remove the pad from the rotor.

So there will be no parasitic drag there.

If you have a car less than 15 years old with dragging rotors, you have a problem that needs to be addressed.

__________________

When you are courting a nice girl an hour seems like a second. When you sit on a red-hot cinder a second seems like an hour. That's relativity.

Albert Einstein

|

|

|

|

|

The Following User Says Thank You to metroschultz For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

04-04-2011, 08:37 PM

04-04-2011, 08:37 PM

|

#122 (permalink)

|

|

EcoModding Jack

Join Date: Nov 2010

Location: Sacramento

Posts: 335

Thanks: 12

Thanked 58 Times in 40 Posts

|

Updates

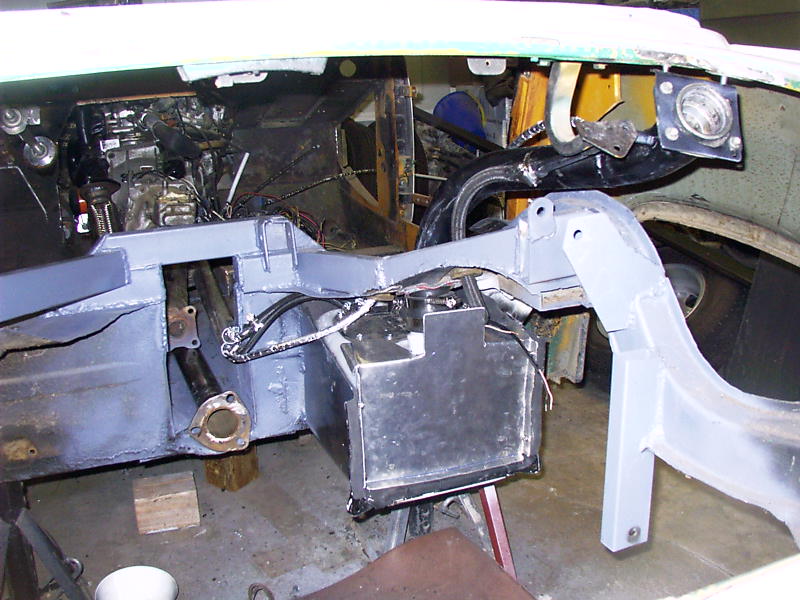

I got the gas tank and all hoses and lines connected up. Lined the box with neoprene rubber, covered the pex tubing with aluminum tape and ran it through aluminum tubing inside the trans tunnel. Used some stainless steel tubing fittings and the buta-n hose and have it all connected ready to go.

I also added an aluminum shroud around the tubing from the tank to the conduit, not shown in this picture.

I have the rearend installed and fabricated the parking brake cable bracket using the stock midget cable. but it was a little too long, so I had a shop make me a new cable a little shorter ($25) using the stock sheath, and it appears to work well.

With the rearend mounted and the engine/trans positioned, I could measure the driveshaft length, and so got that and took the two halfs into Driveshaft Service and they mated them up for me at the right length for $110.

|

|

|

|

04-04-2011, 08:52 PM

04-04-2011, 08:52 PM

|

#123 (permalink)

|

|

EcoModding Jack

Join Date: Nov 2010

Location: Sacramento

Posts: 335

Thanks: 12

Thanked 58 Times in 40 Posts

|

hybrid drive

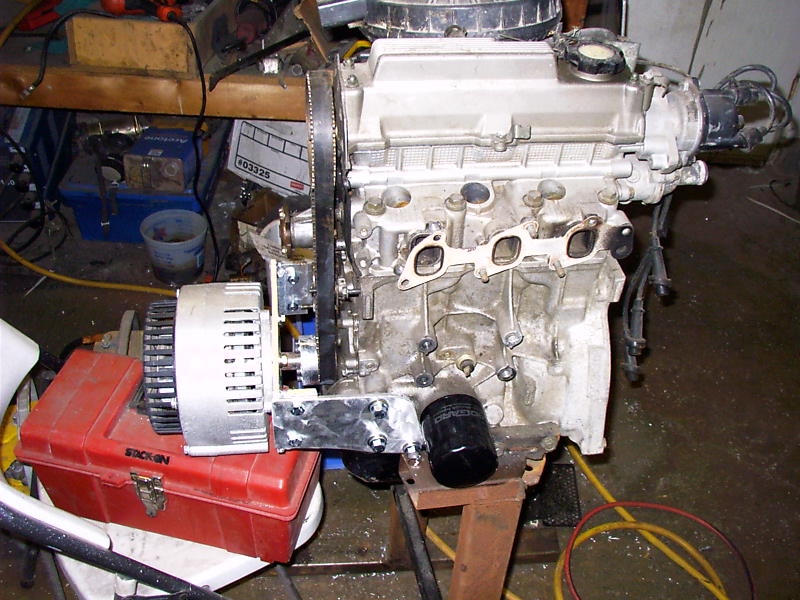

I've decided since this project is taking so gosh darn long, I might as well make it take longer, so I'm going ahead with a hybrid drive.

The idea is to replace the starter motor and the alternator with a motor that can both start the engine, charge the batteries, and use battery power to help propel the vehicle, either for acceleration or just to reduce the fuel needed to move it down the road. This really is one of those "of course" things that car makers should have done a long time ago, but haven't just because why bother to fix something not broken..

I weighed the starter and the alternator, and the front pulley, and their total was 24lbs. I have a 15hp BLDC motor that weighs, guess what, 24lbs.

So the hybrid drive adds no additional weight to the car, except any additional batteries beyond needed to start the car.

I have added a 15hp BLDC motor to the front of the engine, which is one reason I moved the engine back, the motor fits with plenty of room behind the front crossmember. The bad news is that I blew up the motor controller for it that I created (originally for an electric jetski I built). So I'm now working on building another one, this time it will be more robust as paddling back home isn't an option here.

I've also decided to just put this supposedly low-mileage motor in the car. I pulled the plugs and they looked clean, oil was clean, will do a compression test once I can get the engine to spinning with the electric motor.  |

|

|

|

04-04-2011, 09:09 PM

04-04-2011, 09:09 PM

|

#124 (permalink)

|

|

Moderate your Moderation.

Join Date: Nov 2008

Location: Troy, Pa.

Posts: 8,919

Pasta - '96 Volkswagen Passat TDi 90 day: 45.22 mpg (US)

Thanks: 1,369

Thanked 430 Times in 353 Posts

|

So the only time the electric motor will be able to do anything is with the engine spinning?

It's not a bad idea, but is there no way you could get it between the engine and transmission, with the clutch between the gasser and e motor?

This would allow electric only drive, simply by pressing the clutch pedal, but still allow the e motor to s start the engine, provide power assistance, and charge the battery while driving.

__________________

"¿ʞɐǝɹɟ ɐ ǝɹ,noʎ uǝɥʍ 'ʇı ʇ,usı 'ʎlǝuol s,ʇı"

|

|

|

|

04-04-2011, 09:41 PM

04-04-2011, 09:41 PM

|

#125 (permalink)

|

|

Master EcoModder

Join Date: Oct 2009

Location: Red Deer, AB

Posts: 421

Thanks: 39

Thanked 96 Times in 69 Posts

|

Quote:

Originally Posted by metroschultz

Modern disc brakes are designed to completely remove the pad from the rotor.

So there will be no parasitic drag there.

If you have a car less than 15 years old with dragging rotors, you have a problem that needs to be addressed.

|

Interesting comment. Are you sure that is true for all newer cars. My '07 has had slight brake drag since new and brakes on my '03 work van drag a little also.

Nimblemotors, great job on your project.

__________________

Almost all my driving is done 1-5 miles at a time.

Best short trip: 2.4 l/100 km, 3.9 km

|

|

|

|

04-04-2011, 10:35 PM

04-04-2011, 10:35 PM

|

#126 (permalink)

|

|

EcoModding Jack

Join Date: Nov 2010

Location: Sacramento

Posts: 335

Thanks: 12

Thanked 58 Times in 40 Posts

|

Quote:

Originally Posted by Christ

So the only time the electric motor will be able to do anything is with the engine spinning?

|

Right, the motor has a solid direct connection to the engine crankshaft, so if the motor rpm == engine rpm.

Quote:

It's not a bad idea, but is there no way you could get it between the engine and transmission, with the clutch between the gasser and e motor?

This would allow electric only drive, simply by pressing the clutch pedal, but still allow the e motor to s start the engine, provide power assistance, and charge the battery while driving.

|

The real key as I mentioned, is this adds no weight over a traditional gas engine drivetrain, yet could improve mpg. I'll be using a lithium battery pack, that will weigh about the same as a lead-acid starter battery, maybe a little bigger, we'll have to see.

It would take a much bigger motor and probably hundreds of lbs of batteries to power the car any distance without using the gas engine. |

|

|

|

04-04-2011, 10:39 PM

04-04-2011, 10:39 PM

|

#127 (permalink)

|

|

Moderate your Moderation.

Join Date: Nov 2008

Location: Troy, Pa.

Posts: 8,919

Pasta - '96 Volkswagen Passat TDi 90 day: 45.22 mpg (US)

Thanks: 1,369

Thanked 430 Times in 353 Posts

|

I see. As you were, soldier.  .

Don't forget to start the engine using the motor by leaving the clutch engaged and making the vehicle move while the engine cranks!

__________________

"¿ʞɐǝɹɟ ɐ ǝɹ,noʎ uǝɥʍ 'ʇı ʇ,usı 'ʎlǝuol s,ʇı"

|

|

|

|

04-04-2011, 10:56 PM

04-04-2011, 10:56 PM

|

#128 (permalink)

|

|

(:

Join Date: Jan 2008

Location: up north

Posts: 12,762

Thanks: 1,585

Thanked 3,558 Times in 2,220 Posts

|

I'm not aware of any "no-drag" disk brakes setups unless they are very recent.

|

|

|

|

04-04-2011, 11:09 PM

04-04-2011, 11:09 PM

|

#129 (permalink)

|

|

EcoModding Apprentice

Join Date: Jul 2008

Location: Florida

Posts: 135

Thanks: 54

Thanked 16 Times in 14 Posts

|

In the late 80's GM had what they called "quick take up" master cylinders, they had stepped bores that were much larger to get the pads to the rotors quickly then a smaller bore for the actual pressure generation. So there was certainly some effort put into the idea.

Not sure what was done on the caliper end of the system because as far as I know they (mostly) all interchange (GM 1/2 ton trucks circa 70's to early 90's), maybe it was just the MC that did the trick??

|

|

|

|

04-04-2011, 11:33 PM

04-04-2011, 11:33 PM

|

#130 (permalink)

|

|

(:

Join Date: Jan 2008

Location: up north

Posts: 12,762

Thanks: 1,585

Thanked 3,558 Times in 2,220 Posts

|

What I (think I) know is, they've been reducing caliper drag in teensy increments in the last decades but only in the last couple of years have they gotten serious about it and incorporated return spring mechanisms (which I've never seen anywhere but in printed materials). So, unless the disk brake system is a new no-drag design of only a couple year's age, it probably has more drag than any old drum system.

|

|

|

|

|